FRP-RC (fiber reinforced polymer-reinforced concrete) combined beam partially constrained by fiber sleeve and construction method of combined beam

A FRP-RC, local restraint technology, applied in the direction of chemical instruments and methods, joists, girders, etc., can solve the problems that the effect of steel bars cannot be fully exerted, hinder the development of reinforced concrete structures, and hinder the development of high-performance concrete, etc. It is beneficial to the earthquake resistance of the structure, improves the coordination ability of the overall stiffness and deformation, and improves the ultimate compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing:

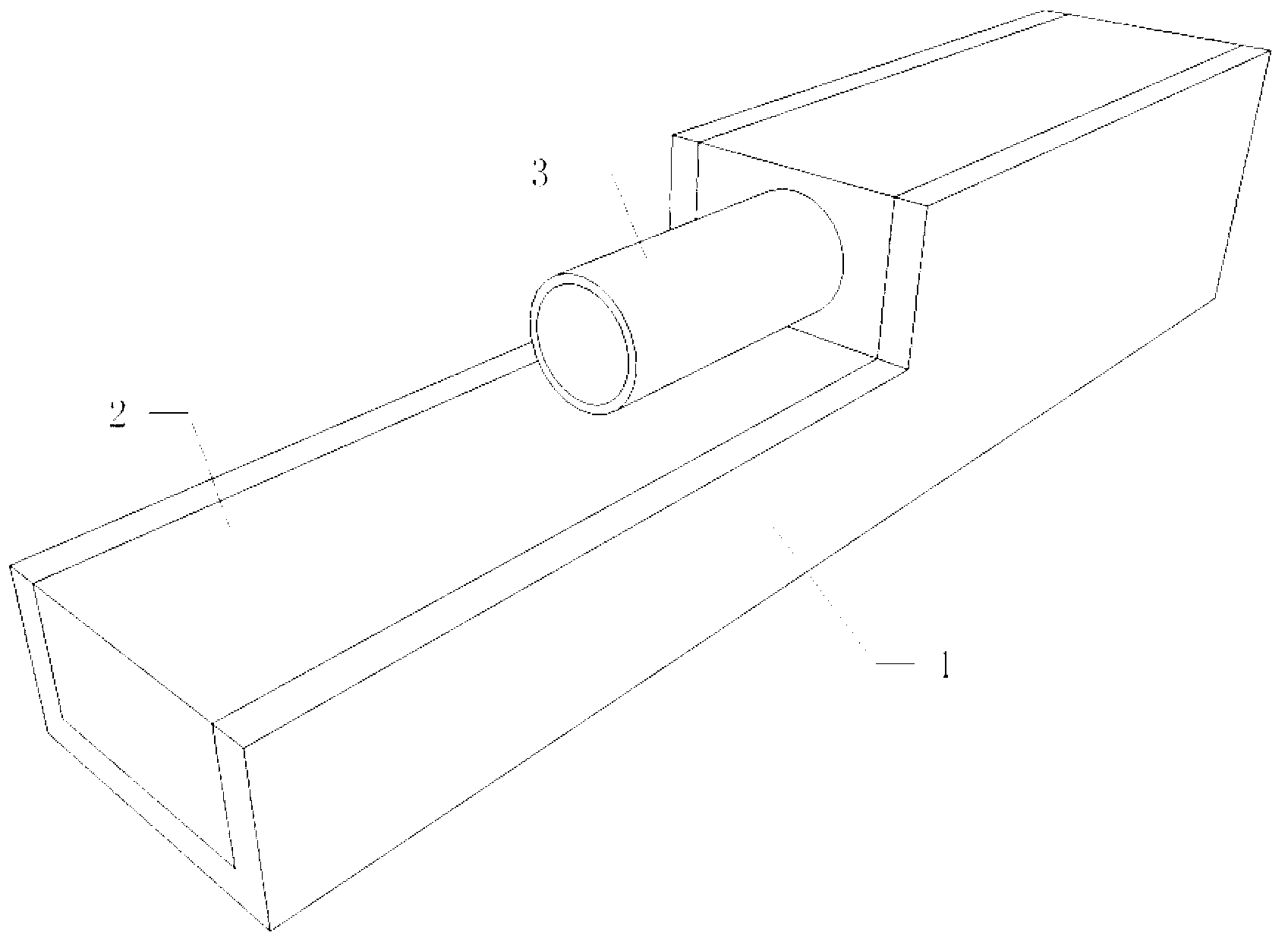

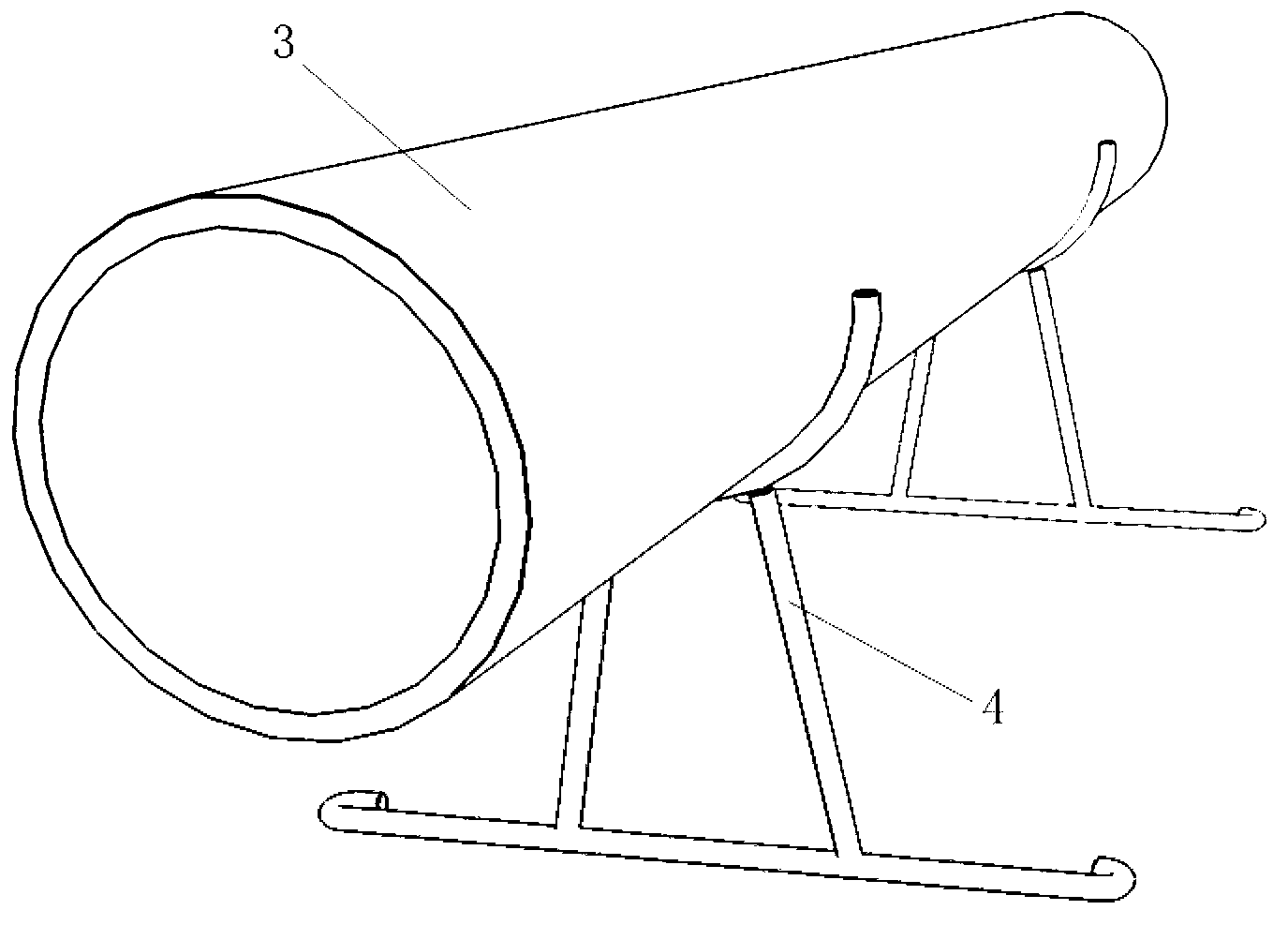

[0025] refer to Figure 1 to Figure 6 , the locally constrained fiber casing FRP-RC composite beam of the present invention, the steps are as follows:

[0026] 1) Preparation:

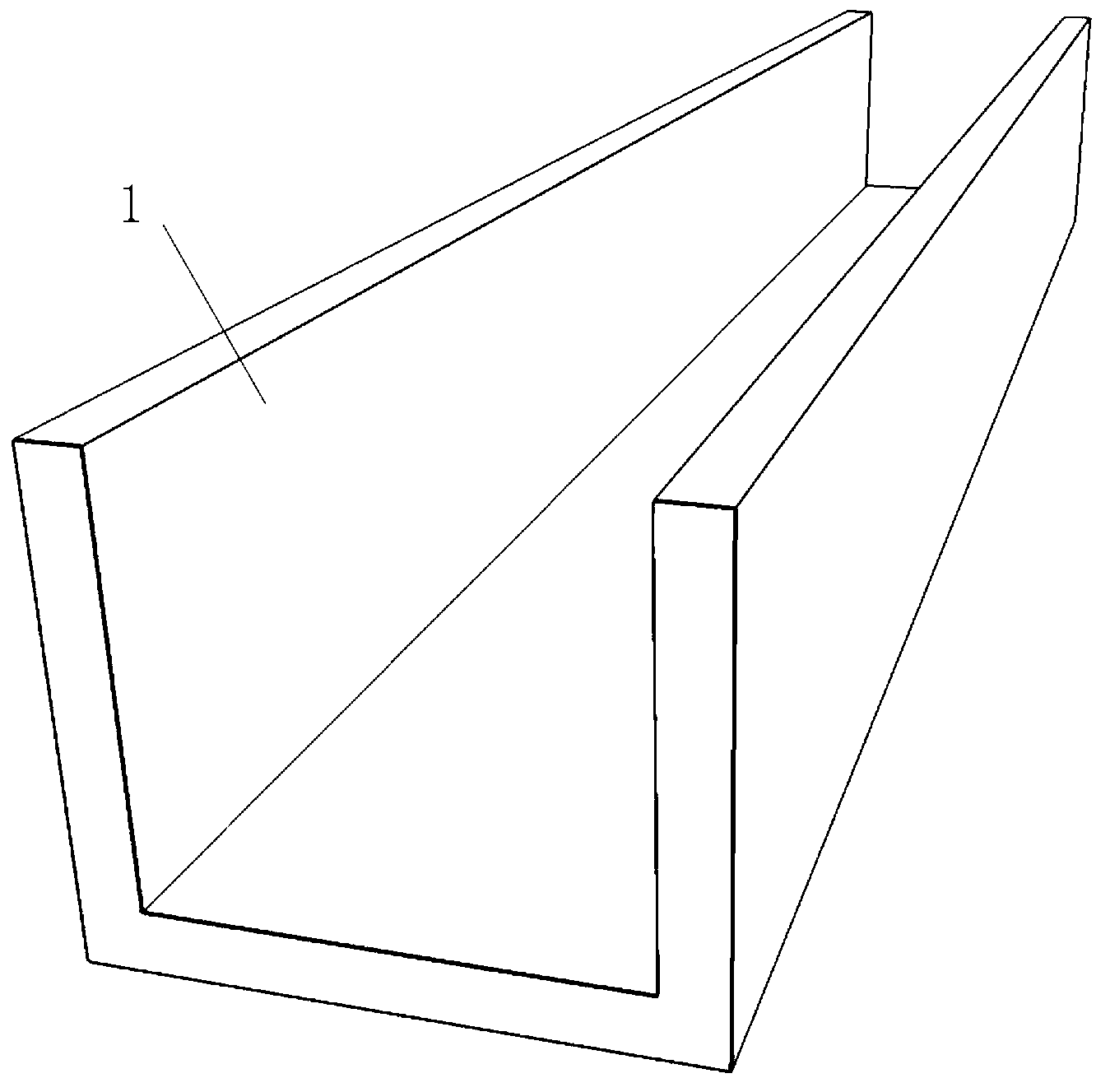

[0027] a) see figure 2 , The production of FRP formwork: make a U-shaped wooden formwork in advance according to the required size; spread the fiber cloth cut according to the design on a flat plastic film, impregnate it with epoxy resin, and lift it together with the plastic film Put it into the U-shaped wooden formwork according to the predetermined position, and then use a scraper to make it adhere to the formwork, and lay the corresponding layers according to the same steps; then, put the impregnated fiber cloth in the formwork according to the predetermined The laying method is pasted vertically, and rolled with rollers to make it completely soaked and pasted tightly, and pay atte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com