LVL structure and melamine paper facing novel plate and manufacturing method thereof

A technology of melamine paper and new boards, applied in chemical instruments and methods, paper/cardboard layered products, building components, etc., can solve the problems of short service life, poor use effect and low technical content of density boards, and achieve the goal of using Reduced amount of glue, good use effect, and good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment:

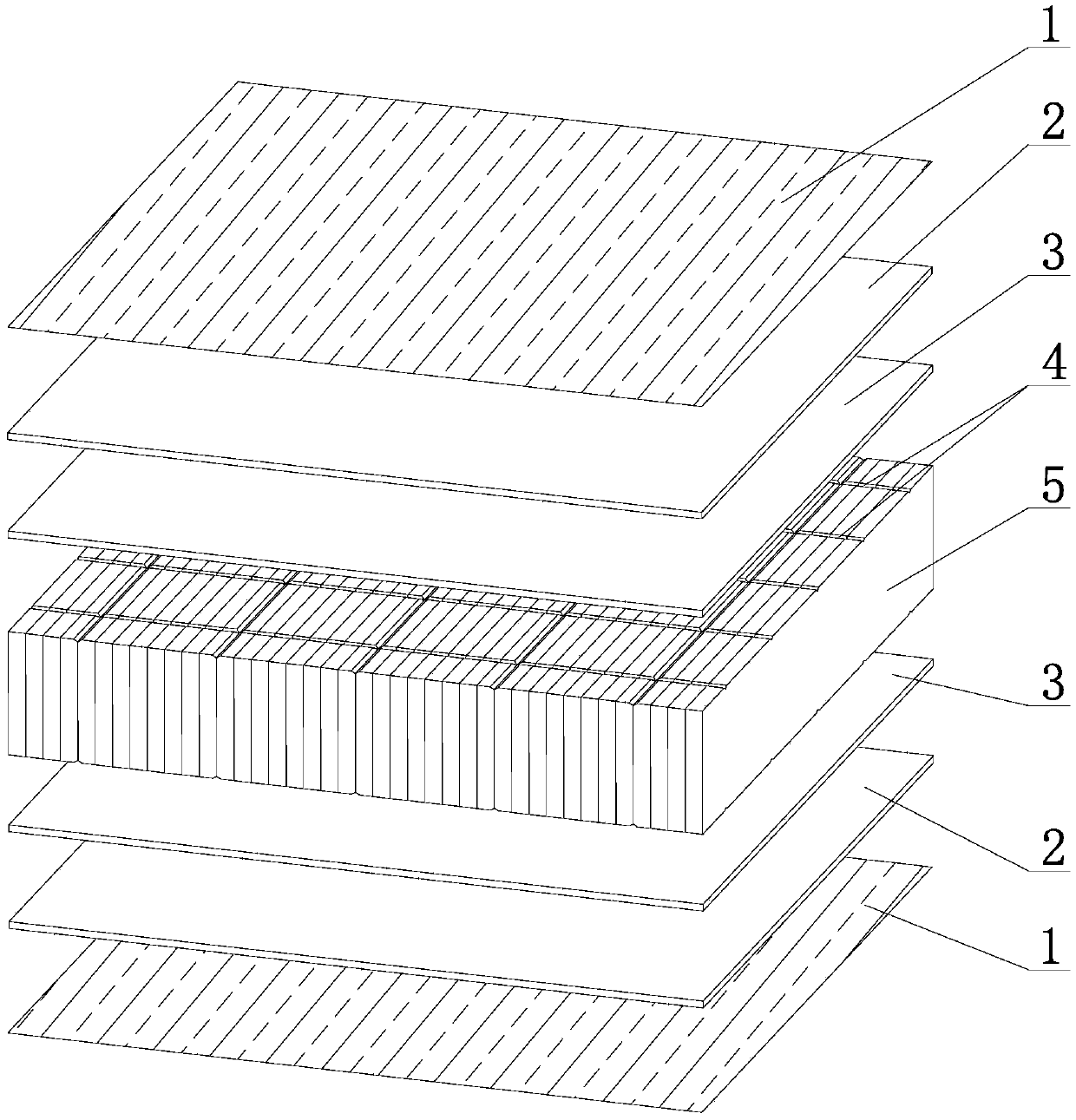

[0030] Such as figure 1 As shown, the LVL structure melamine paper facing novel plate of the present invention comprises an LVL structure layer 5, and from the LVL structure layer 5 outwards, there are successively attached wood veneers I3, wood veneers II2, and wood veneers II2 are surface-mounted There is melamine paper 1.

[0031] Among them, the thickness of the LVL structure layer 5 is 12 mm, the thickness of the wood veneer I3 and wood veneer II2 is 2 mm, and the thickness of the melamine paper 1 is ignored, and the overall thickness of the board is 20 mm.

[0032] The upper and lower sides of the LVL structure layer 5 in this embodiment are punched with fiber breaking grooves 4 by punching knives.

[0033] The fiber breaking grooves 5 of the present embodiment are distributed in a well shape.

[0034] The depth of the fiber breaking groove 5 of the present embodiment is 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com