Patents

Literature

37results about How to "Improve environmental protection factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

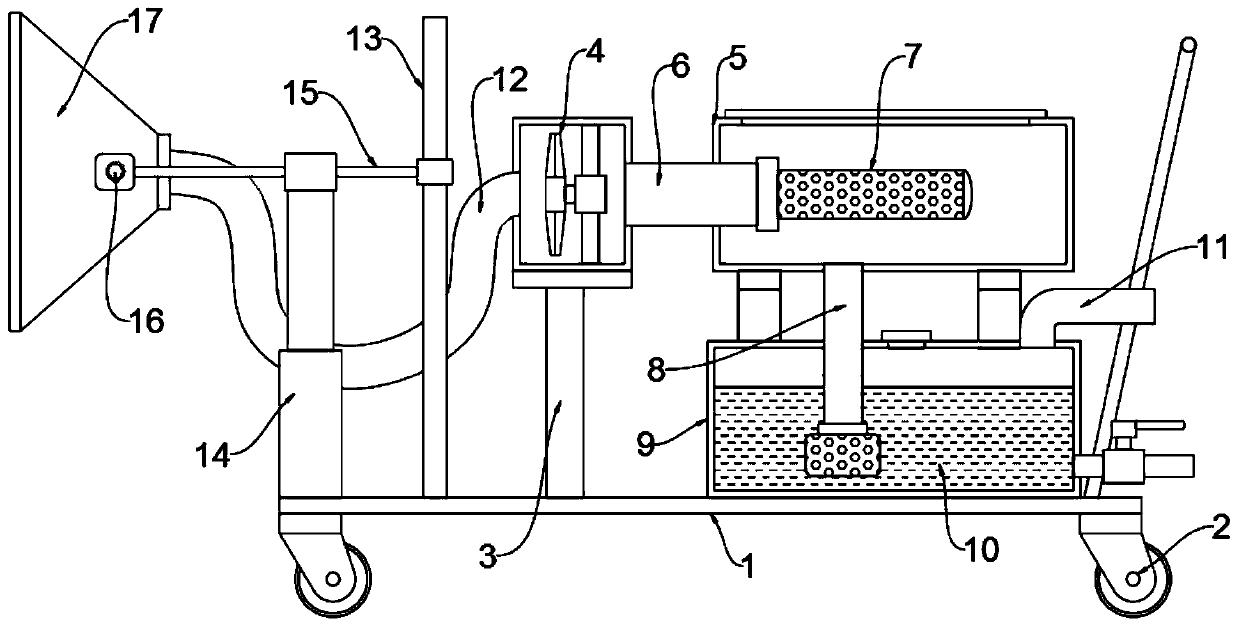

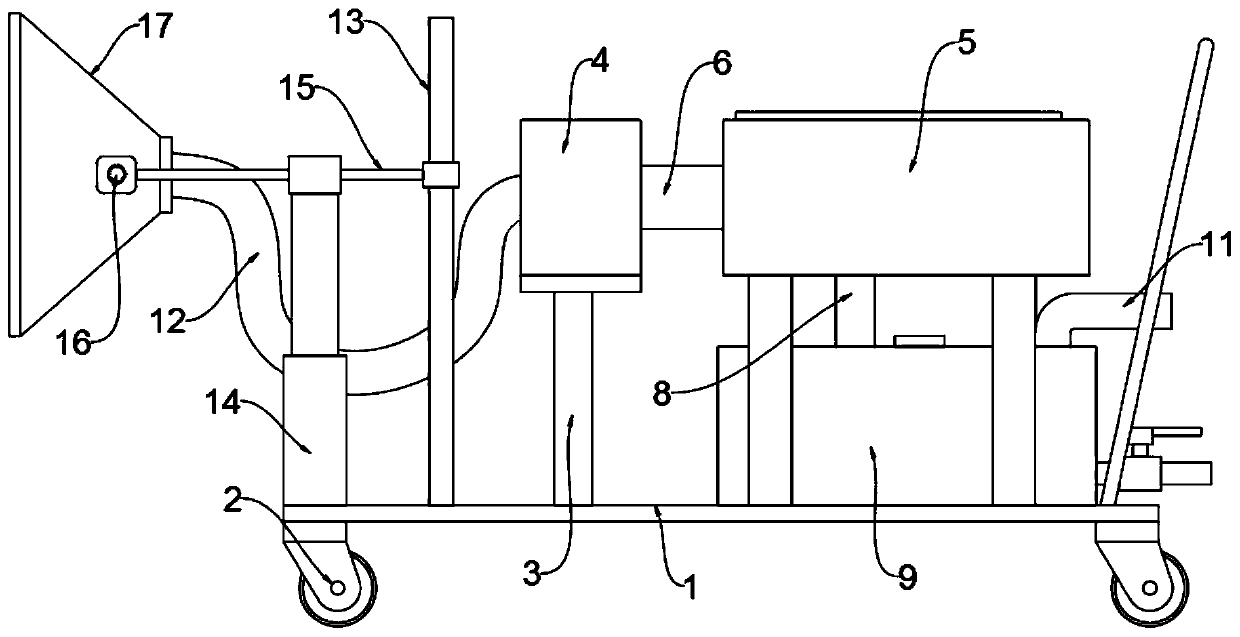

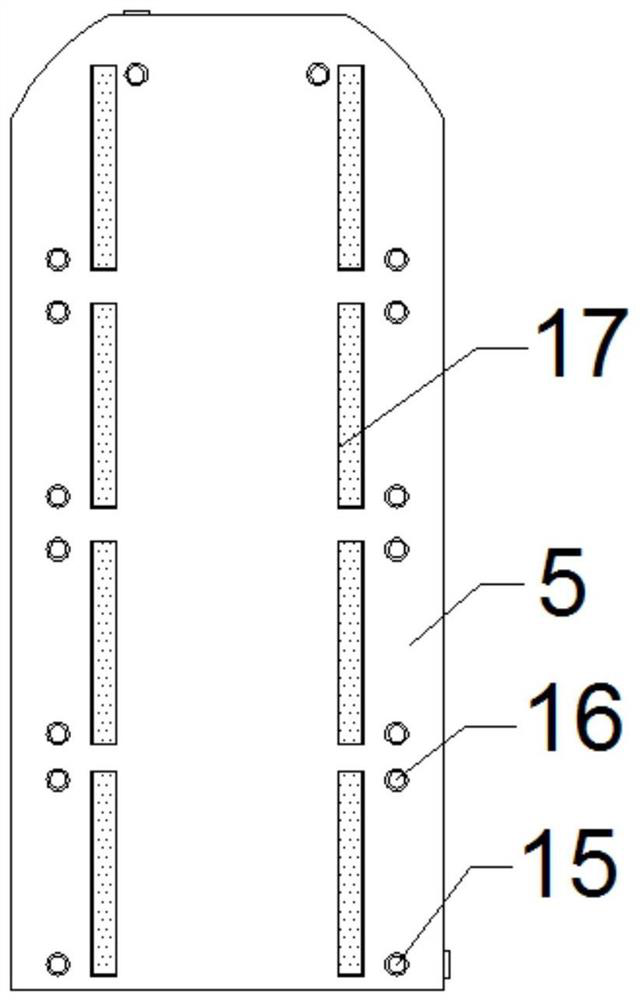

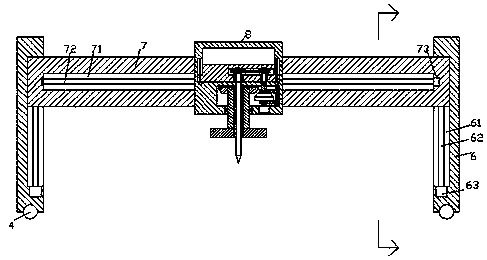

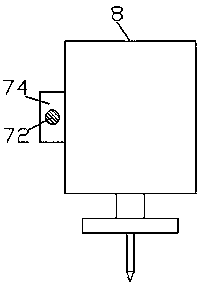

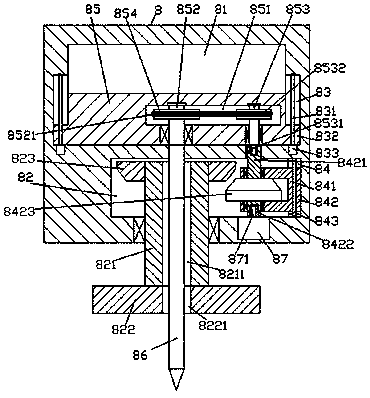

Environment-friendly dust removal device

ActiveCN107116462AReduce investmentReduce manufacturing costGrinding drivesLapping machinesScrew joint

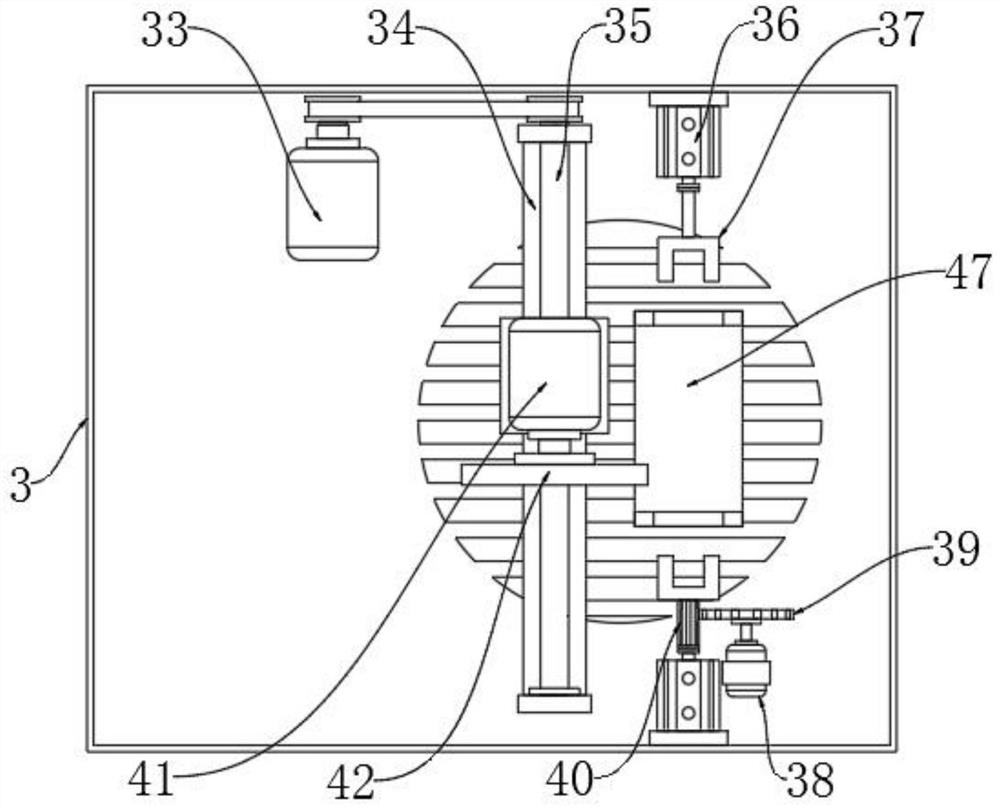

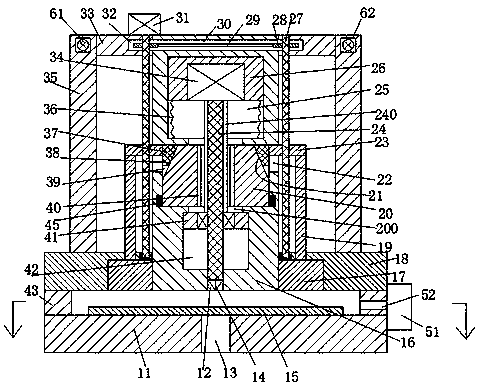

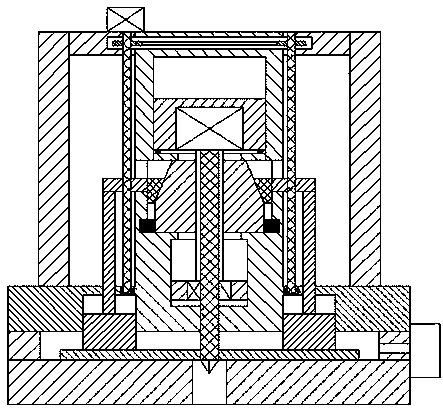

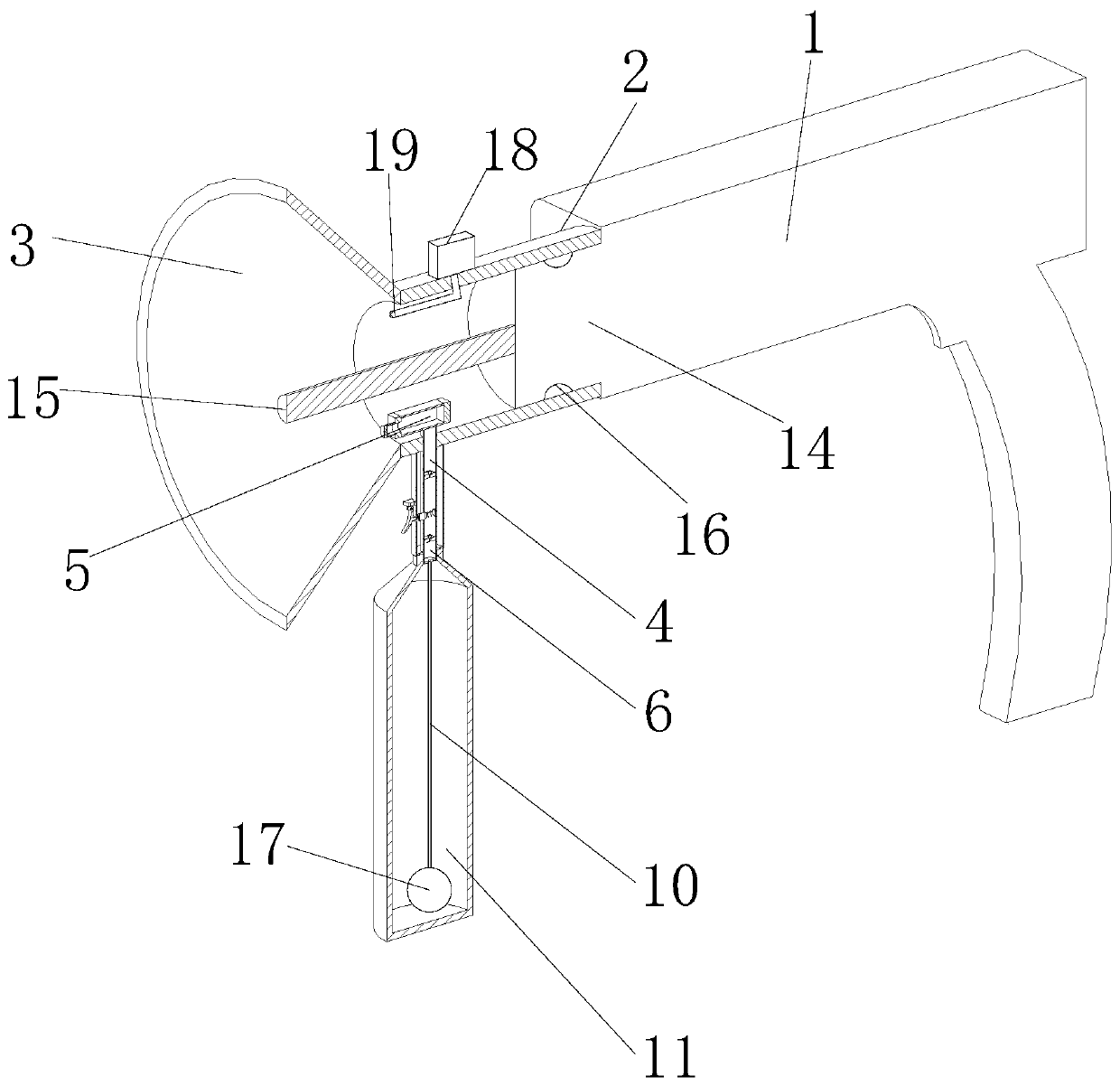

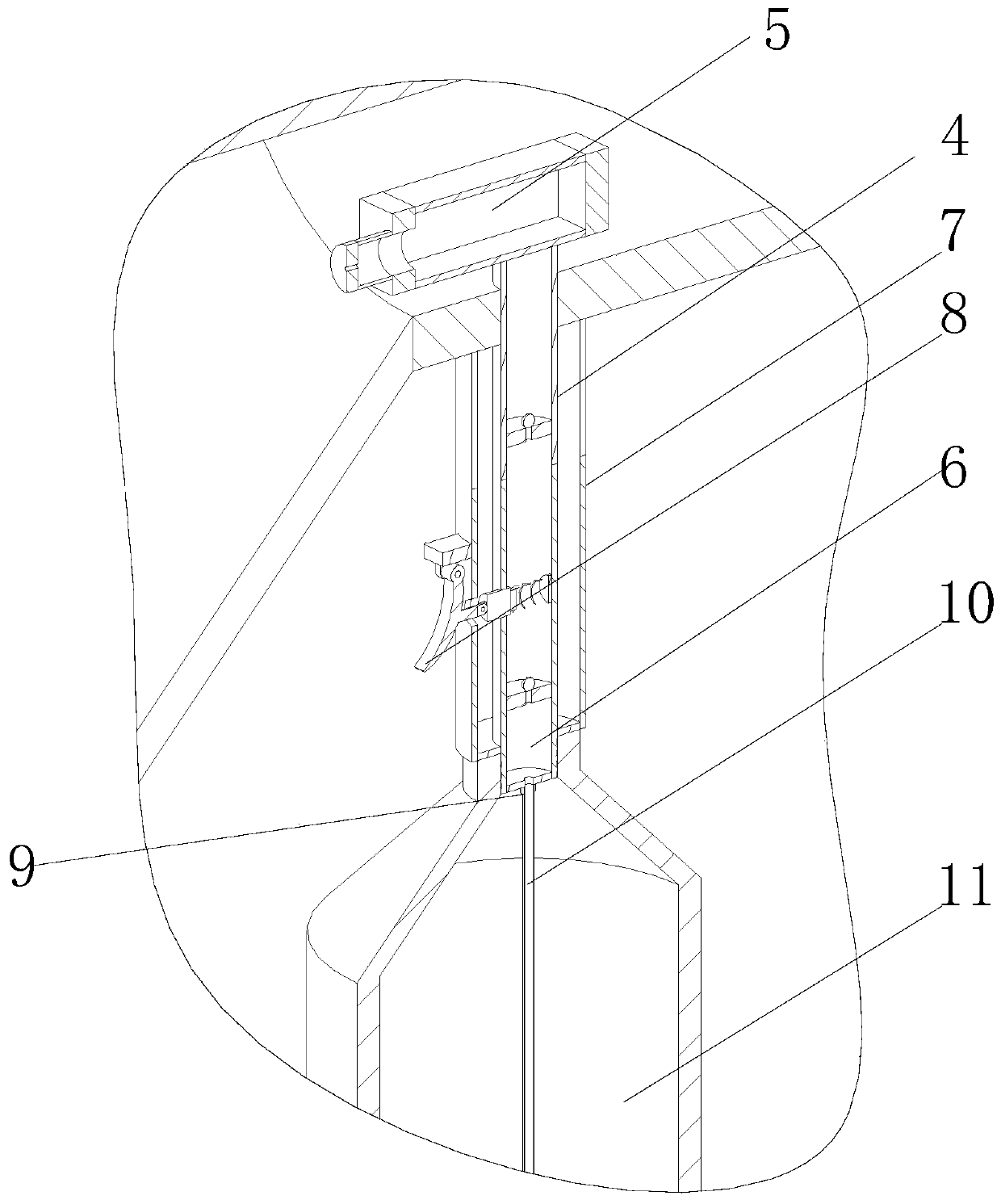

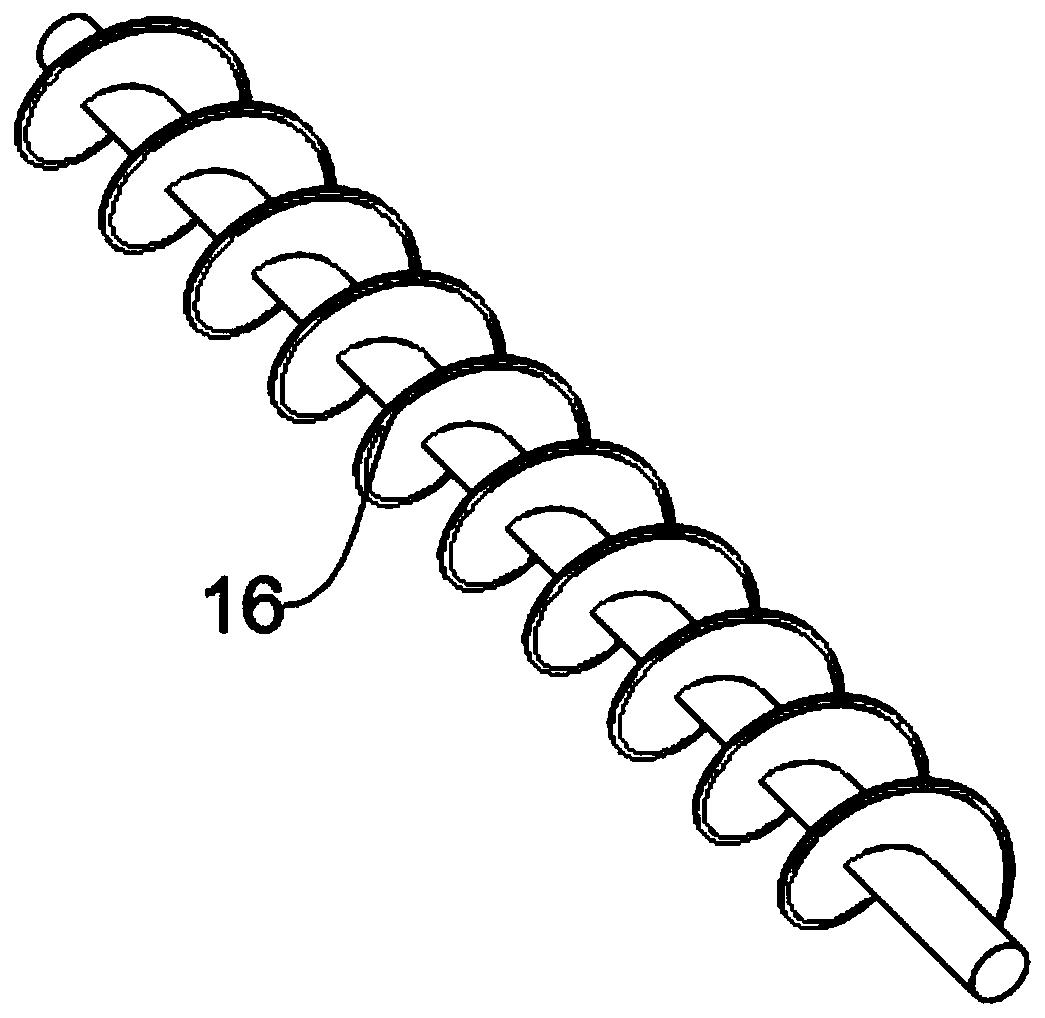

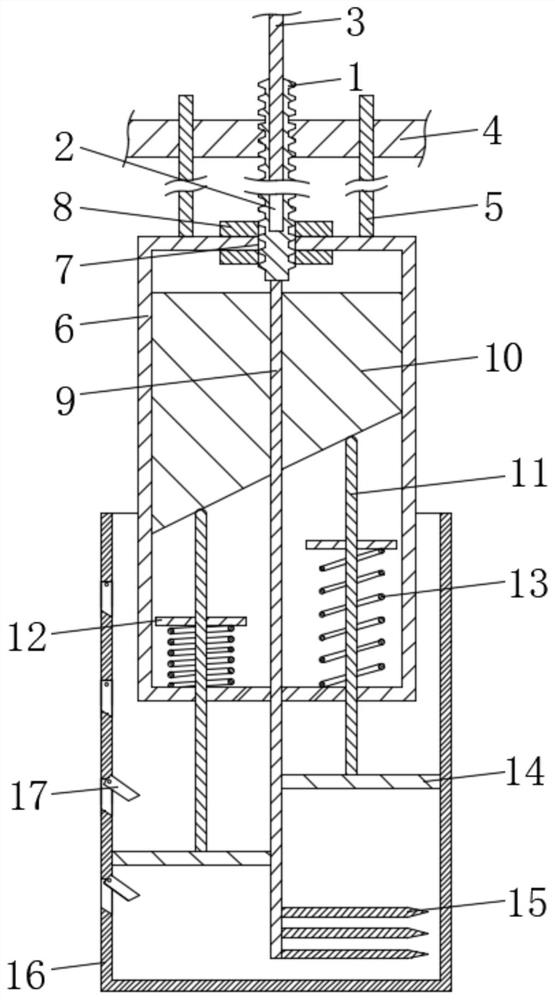

The invention discloses an environment-friendly dust removal device. The environment-friendly dust removal device comprises a frame composed of supporting feet and a top plate, universal wheels are arranged at the bottoms of the supporting feet, a control pipe device is arranged in the frame, a first cavity is formed in the control pipe device, first sliding connection grooves are equally formed in the left side inner wall and the right side inner wall of the first cavity, first screw joint rods are arranged in the first sliding connection grooves, a first sliding connection block is in movable fit connection with the interior of the first cavity, a second cavity is formed in the position, below the first cavity, in the control pipe device, a guide connection groove is formed in the inner wall of the right side of the second cavity, a guide connection rod is arranged in the guide connection groove, a guide connection frame with the left side penetrating into the second cavity is in movable fit connection with the guide connection rod, and a first inclined wheel is arranged in the guide connection frame penetrating into the second cavity. The device is simple in structure and convenient to operate, and has multiple purposes, equipment investment is reduced, the metal workpiece clamping and positioning frequency is reduced, time and labor are saved, dust after grinding can be treated in the same device, and the environment-friendly coefficient is high.

Owner:JIANGSU XINYE HEAVY IND

Dustproof protective cover

PendingCN110960946AImprove functionalityAvoid pollutionCombination devicesEngineeringStructural engineering

Owner:常州威华电子股份有限公司

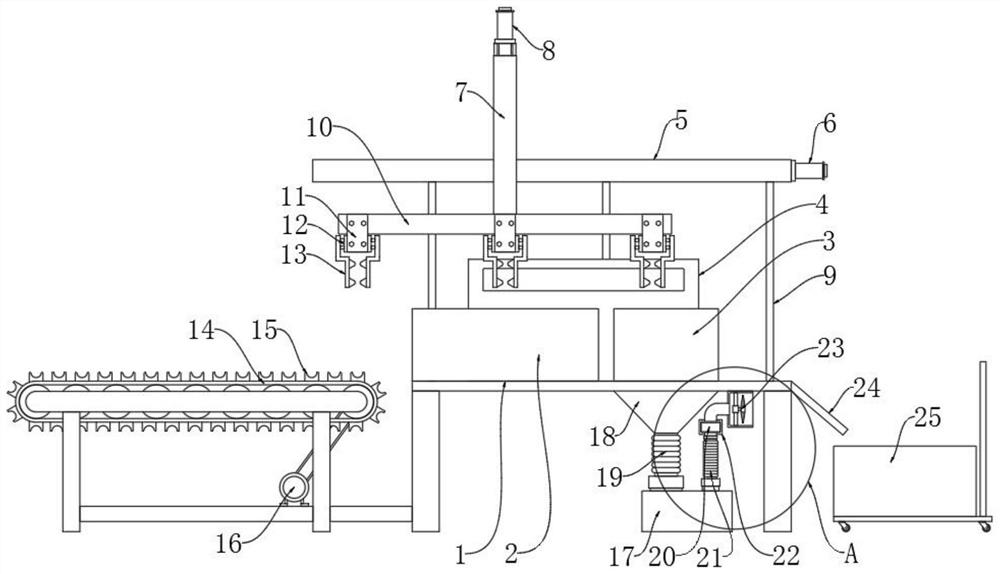

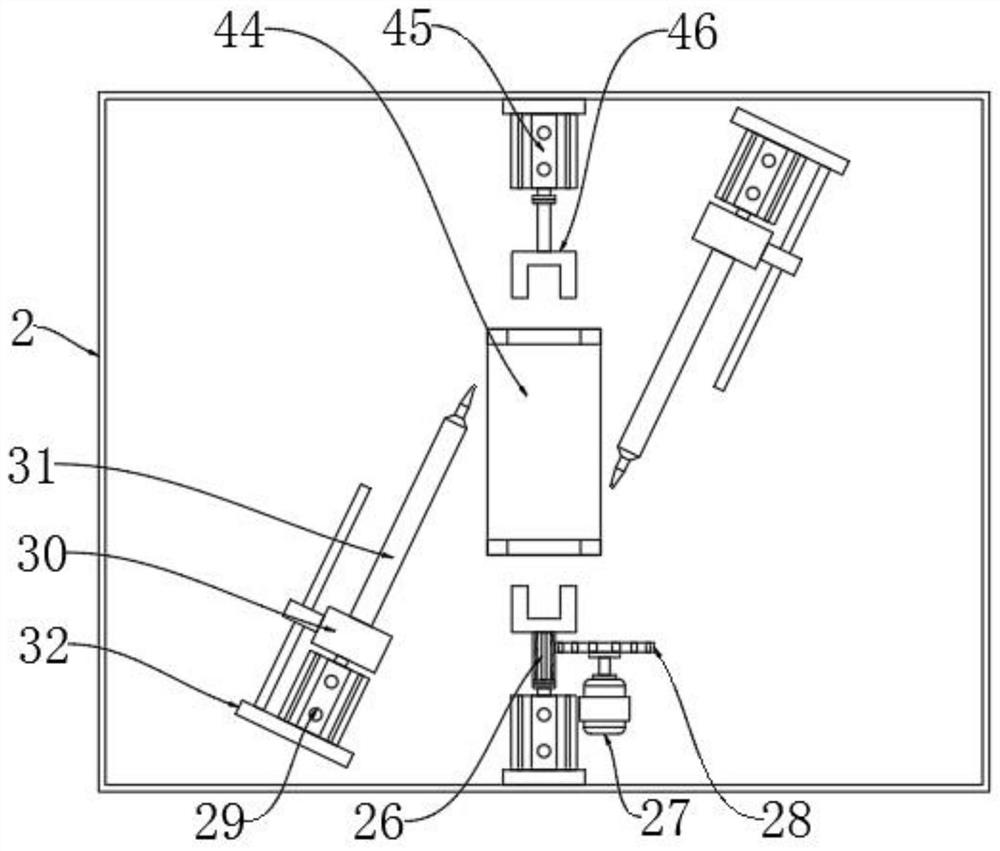

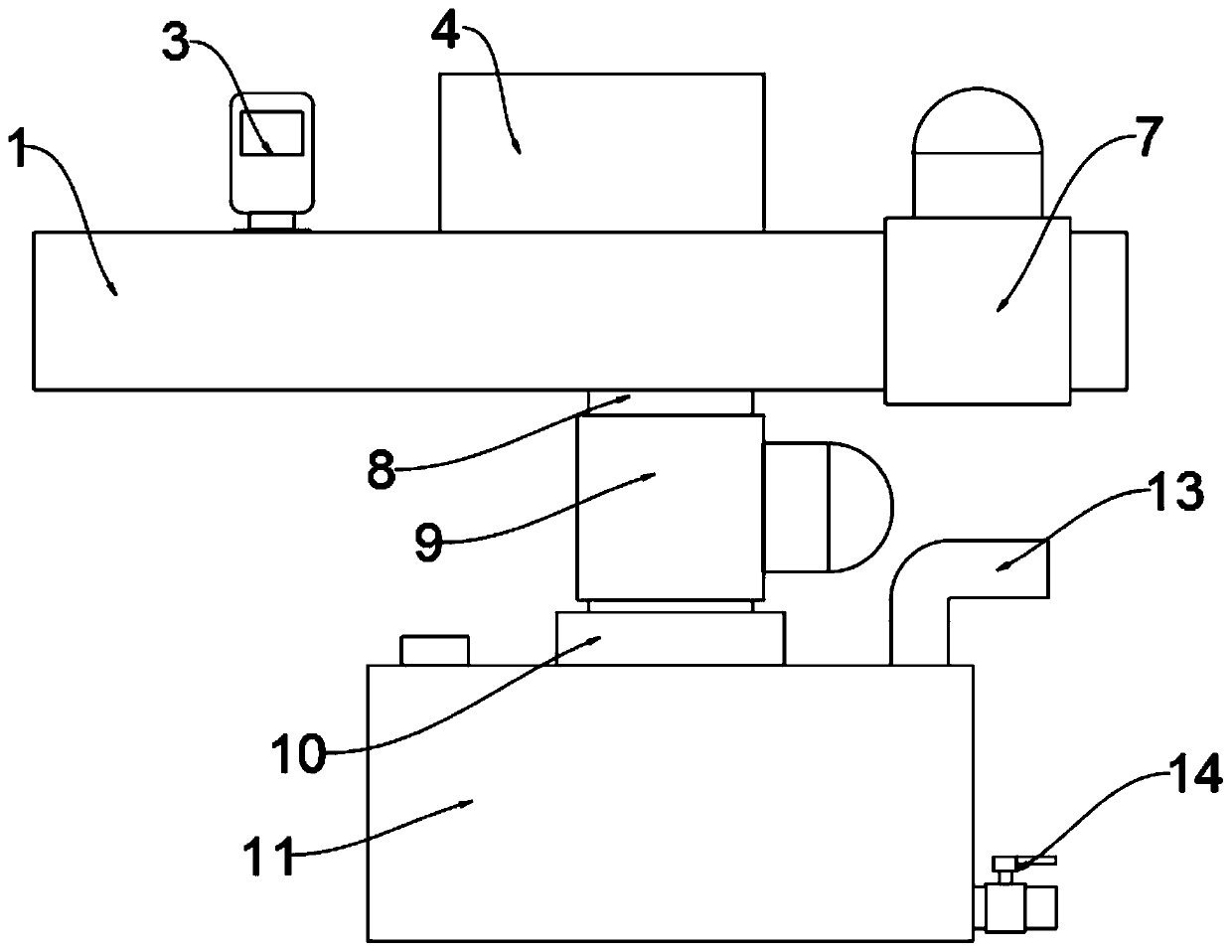

Efficient full-automatic laser welding system

PendingCN111940903ARealize fully automated production and processingIncrease productivityGrinding machinesGrinding feedersRotational axisElectric machinery

The invention discloses an efficient full-automatic laser welding system. The system comprises a supporting base, wherein a welding mechanism, a grinding mechanism, a cooling box and a fixing supportframe are arranged on the outer surface of the upper end of the supporting base, a movable cross beam is fixedly connected to the top end of the fixing support frame, a first motor is arranged at oneend of the movable cross beam, a lead screw is fixedly connected to one end of a rotating shaft of the first motor, the lead screw penetrates through the inner part of the movable cross beam, the outer part of the movable cross beam is sleeved with a movable block, the movable block is in threaded connection with the lead screw in the movable cross beam, a movable longitudinal beam is arranged onone side of the movable cross beam, and a second motor is arranged at one end of the movable longitudinal beam. According to the efficient full-automatic laser welding system, feeding, transferring and discharging can be synchronously operated, meanwhile, welding, air cooling and grinding can be synchronously carried out, full-automatic production and machining are achieved, and the production efficiency is effectively improved.

Owner:浙江施克汽车配件有限公司

Production method for environment-friendly bamboo mat

InactiveCN107457877AImprove environmental protection factorWood treatment detailsCane mechanical workingMaterials scienceRaw material

The invention discloses a production method for an environment-friendly bamboo mat. The production method comprises the following steps of raw material felling, material cutting, bamboo splitting, sheet splitting, filament drawing, digesting, drying, dyeing, bamboo filament sorting and weaving.

Owner:王莉

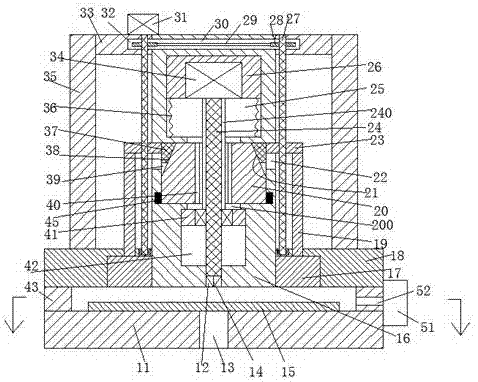

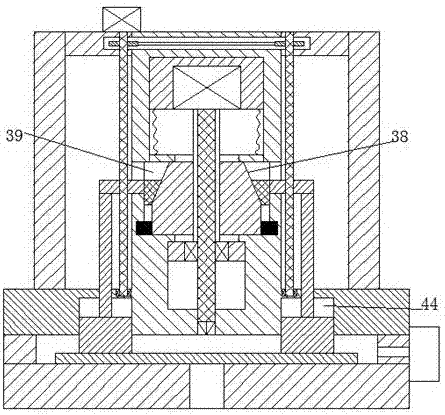

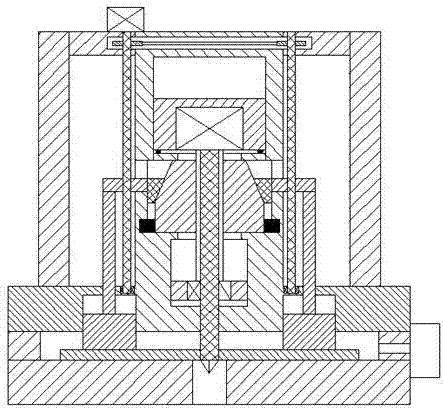

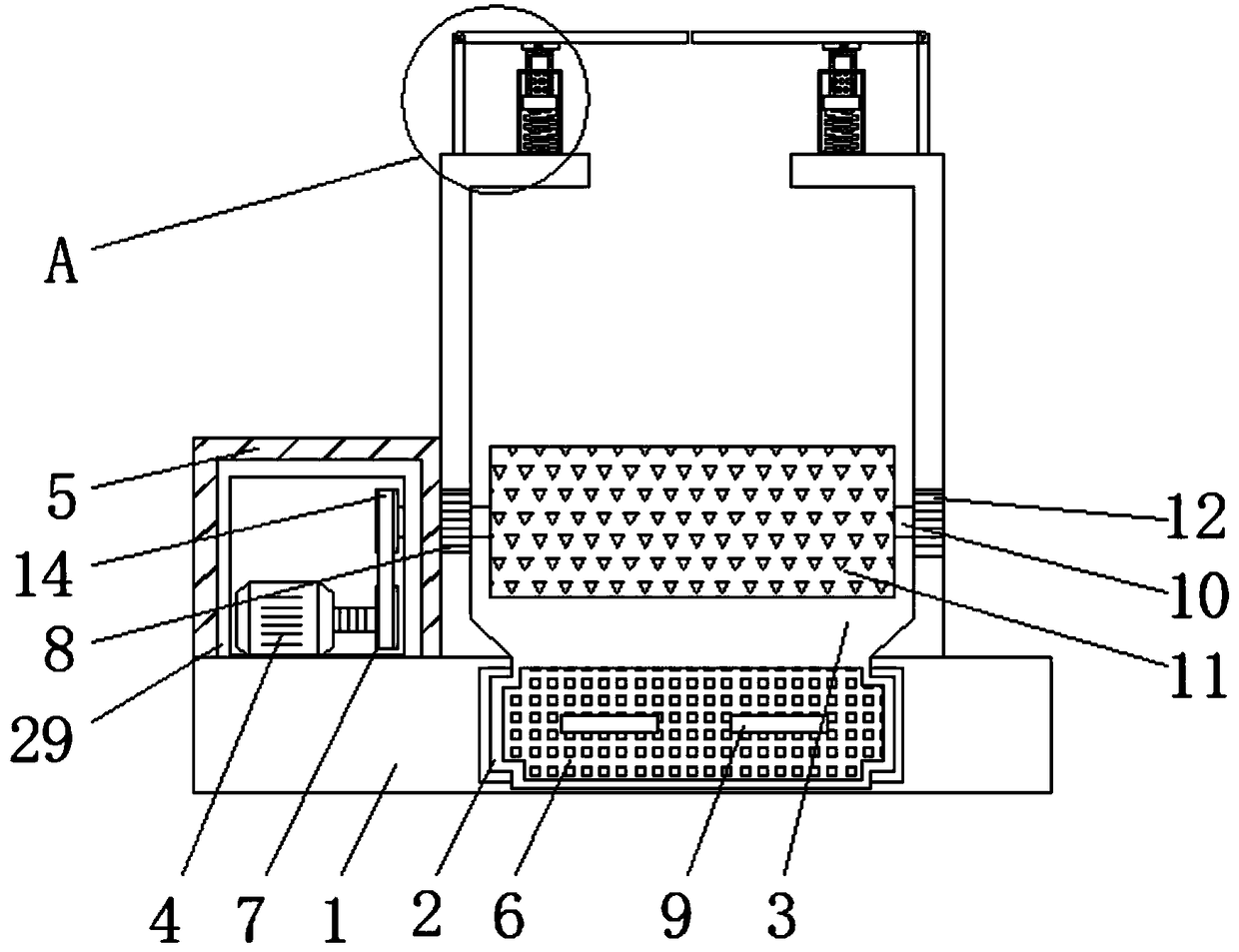

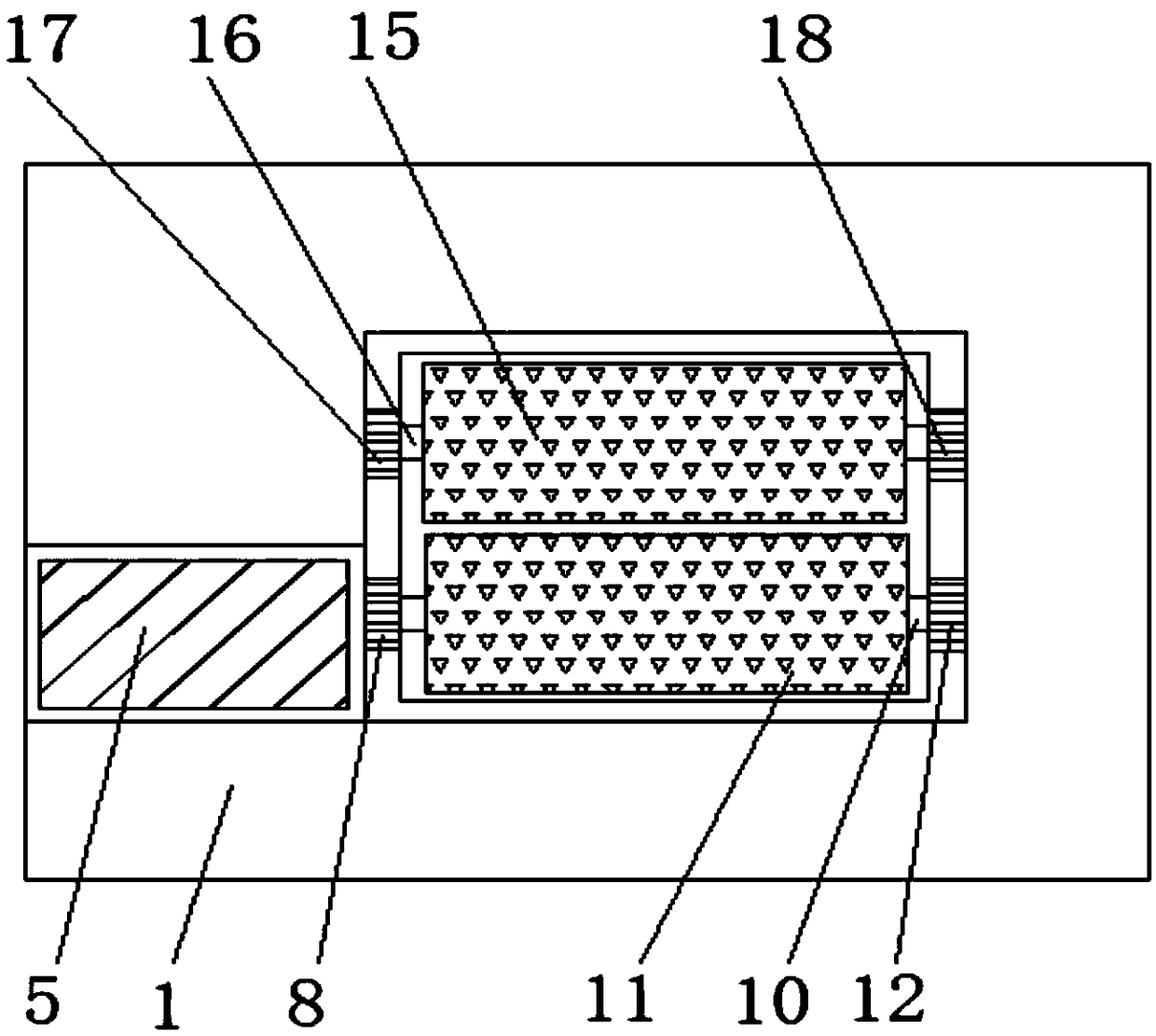

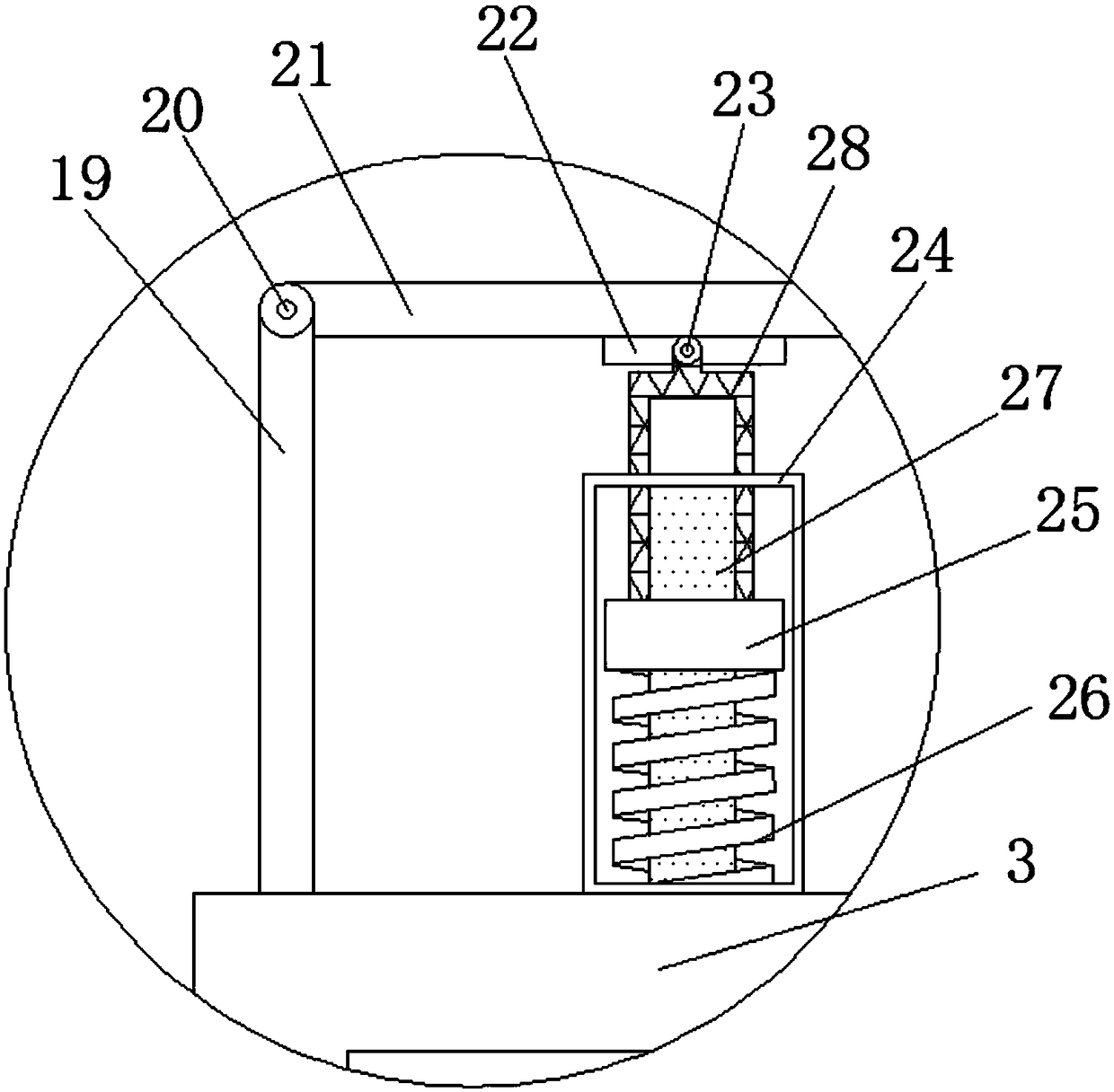

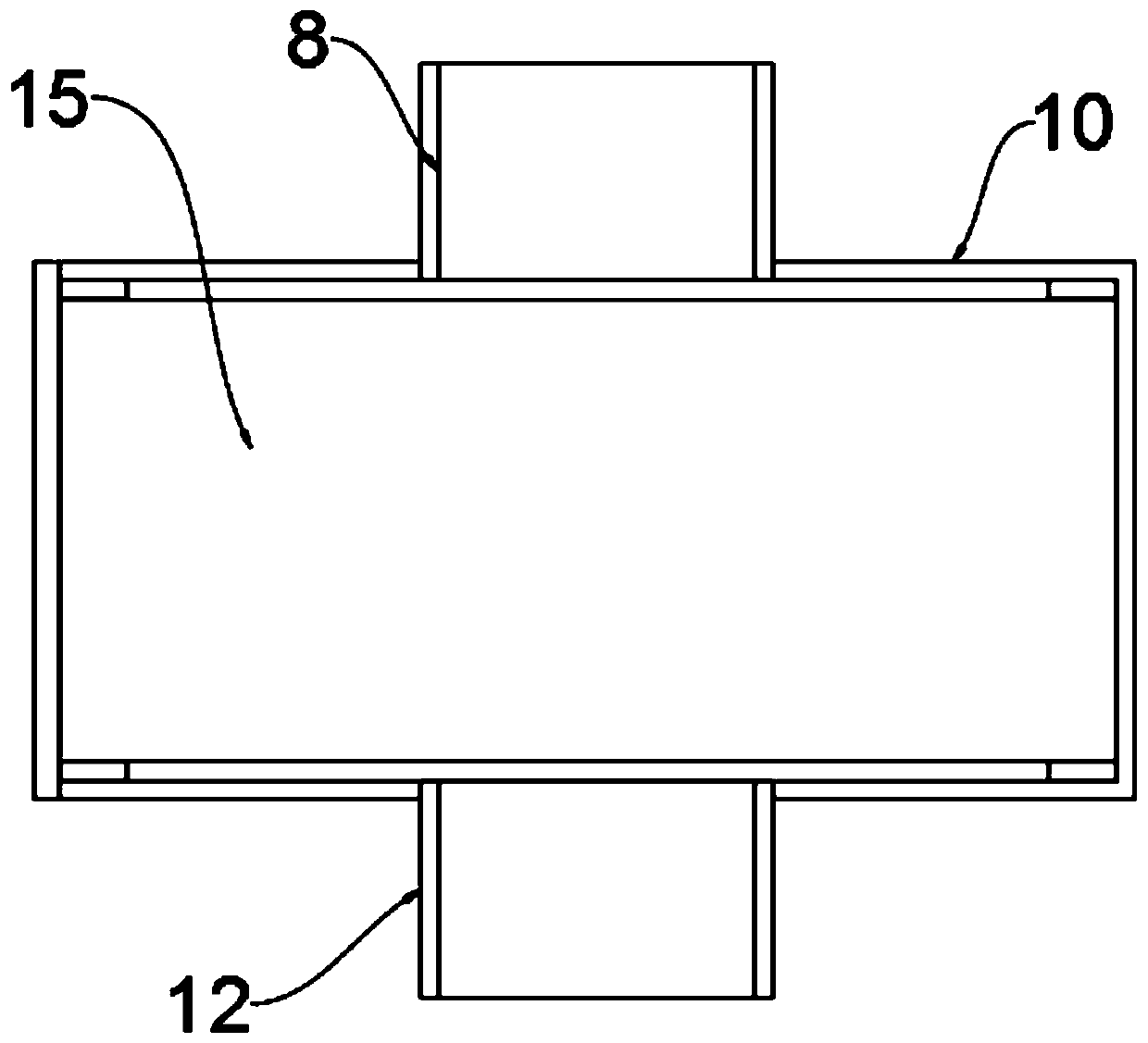

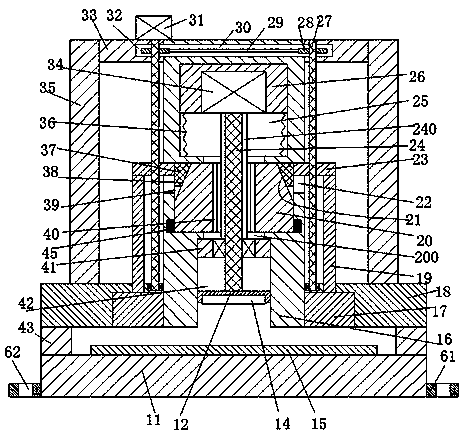

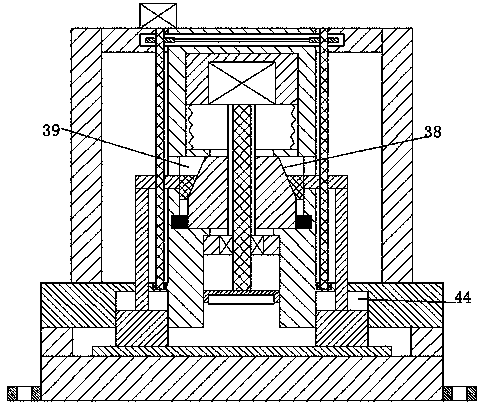

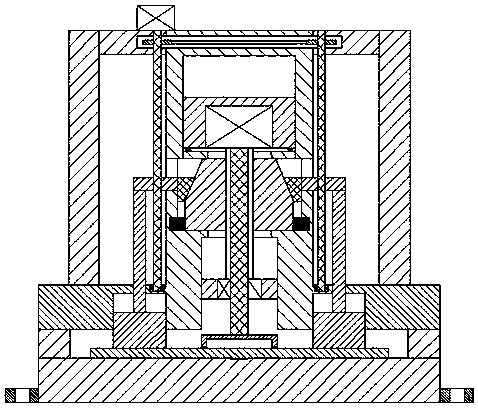

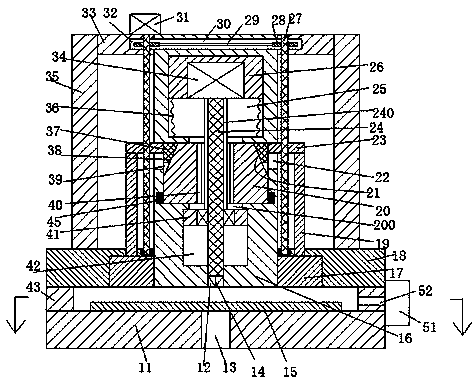

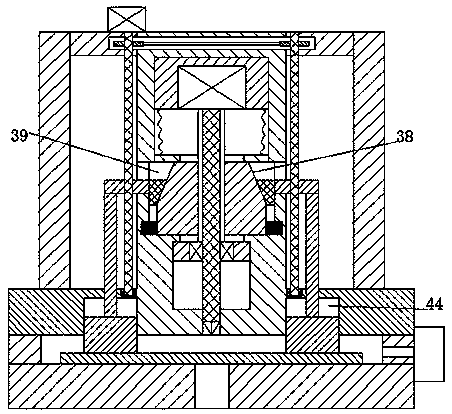

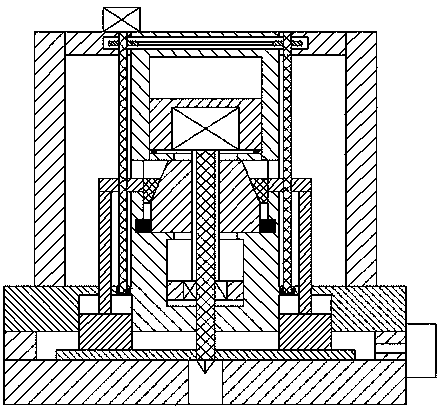

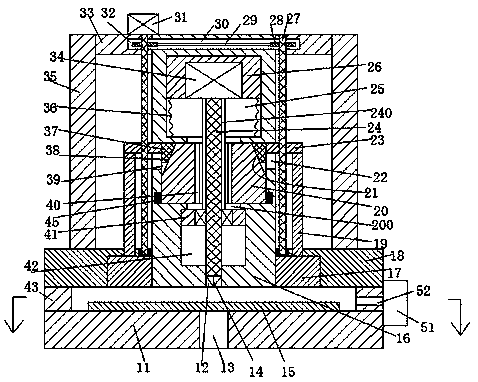

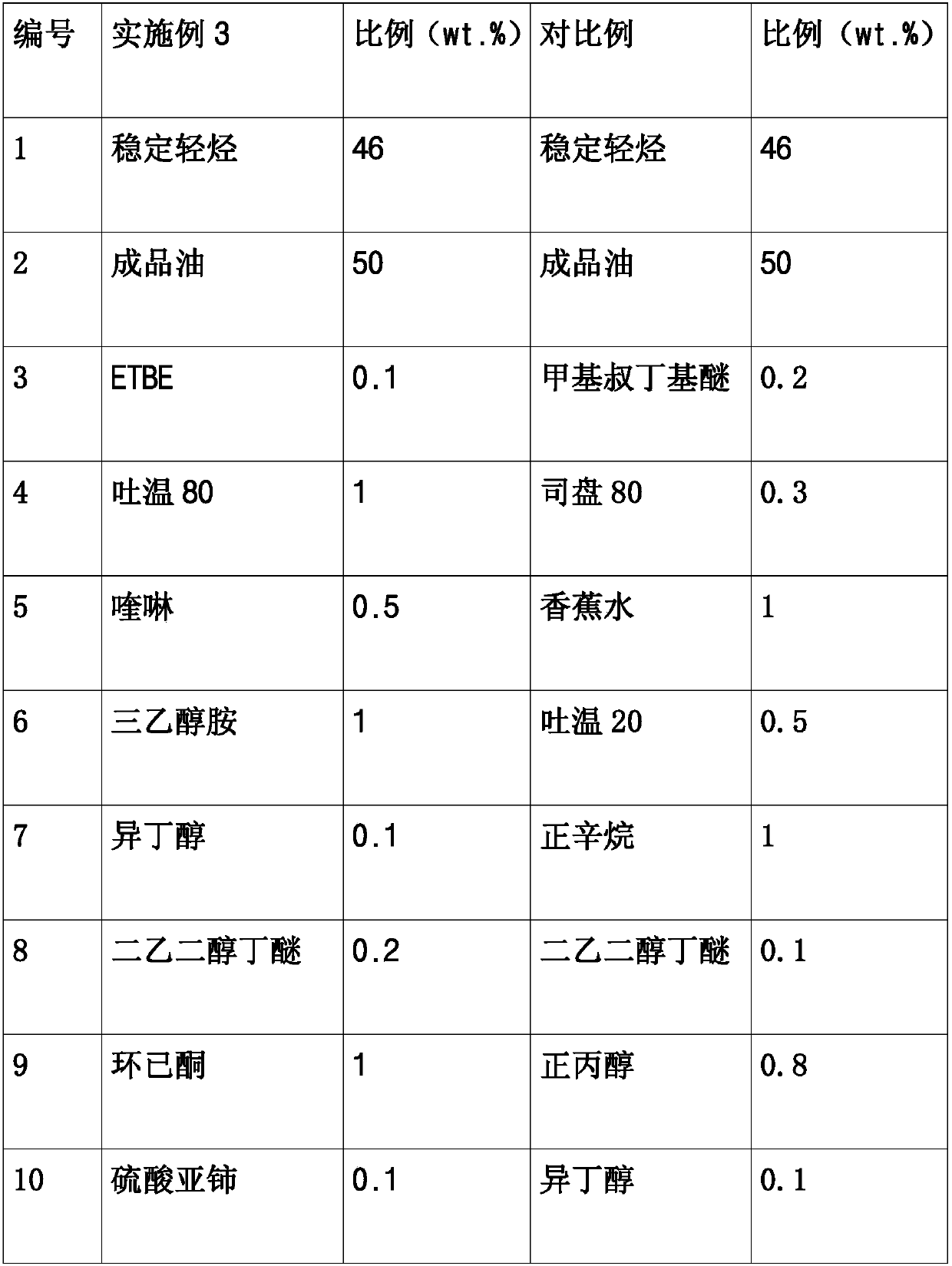

Environment-friendly grinding equipment

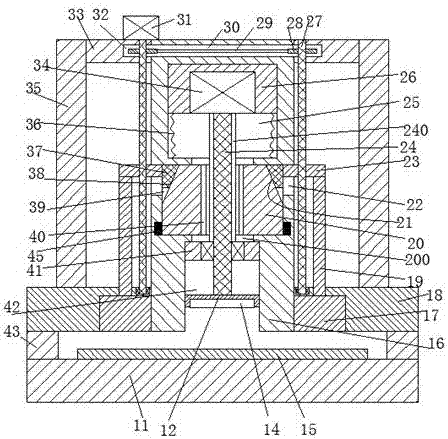

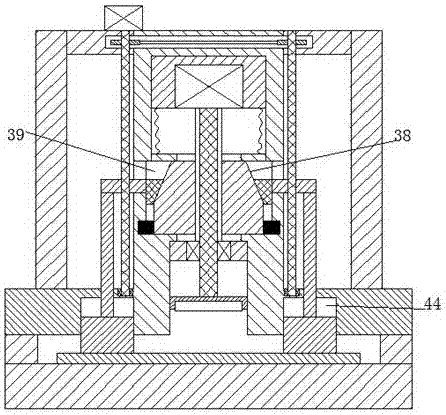

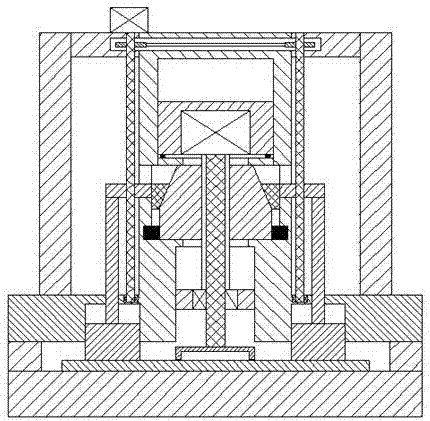

ActiveCN107457632AAvoid injuryEffective isolationGrinding carriagesGrinding feedersArchitectural engineeringBilateral symmetry

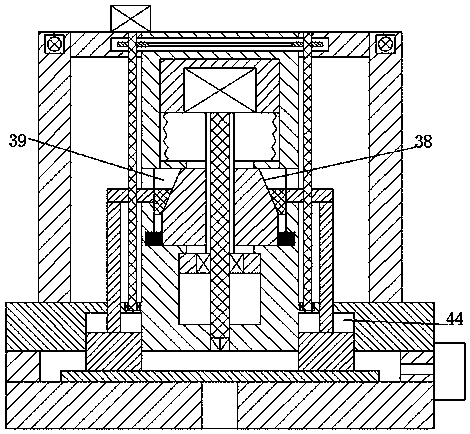

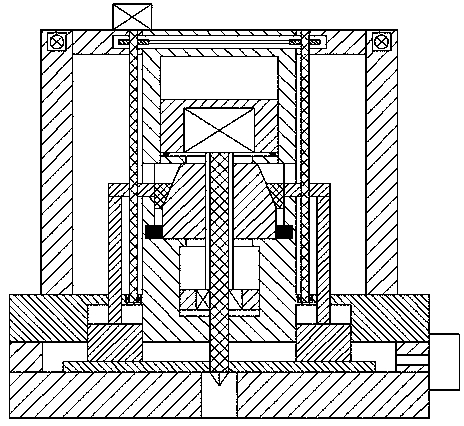

The invention discloses environment-friendly grinding equipment used for grinding steel plates. The environment-friendly grinding equipment comprises a bottom support for installation of the steel plates and a clamping base fixedly installed on the bottom support through supporting frames; a center hole is formed in the center of the clamping base; a center frame is fixedly installed in the center hole, the upper end of the center frame extends upwards, and top frames are symmetrically installed on the two sides of the upper end of the center frame; a vertical frame is fixedly installed between each top frame and the clamping base; an upper sliding cavity, a middle sliding cavity and a lower sliding cavity are formed in the center frame; a through connecting groove is formed between the middle sliding cavity and the upper sliding cavity, and another through connecting groove is formed between the middle sliding cavity and the lower sliding cavity; an upper sliding frame is vertically movably installed in the upper sliding cavity; a lower sliding frame is vertically movably installed in the lower sliding cavity; and sliding connecting blocks are horizontally movably installed in the middle sliding cavity in a bilateral symmetry mode.

Owner:新沂市华洋金属制品有限公司

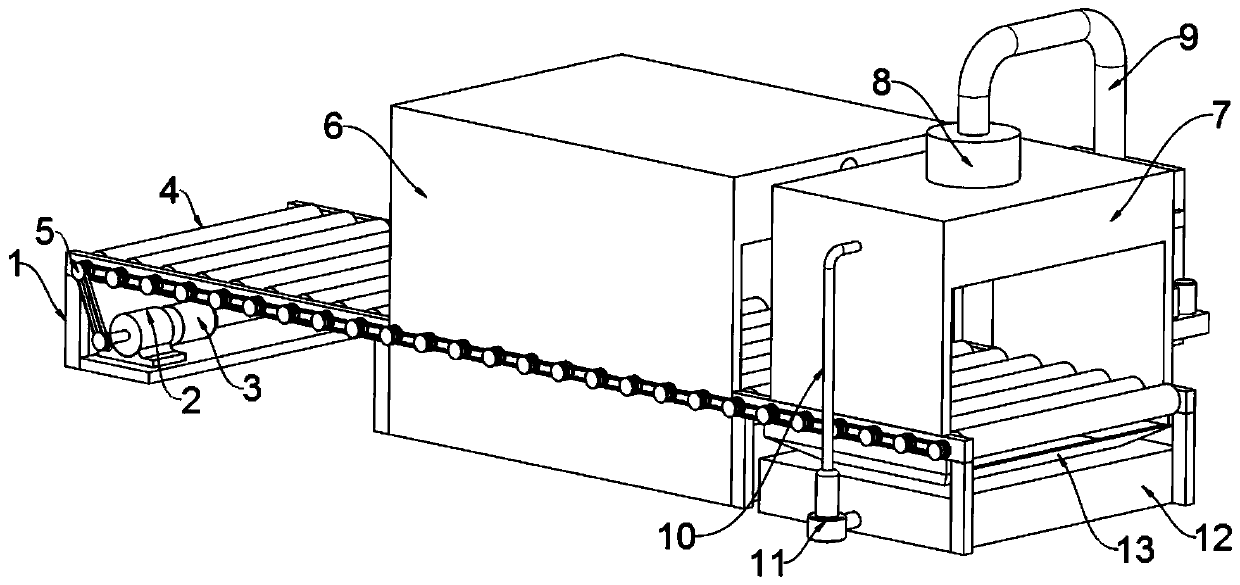

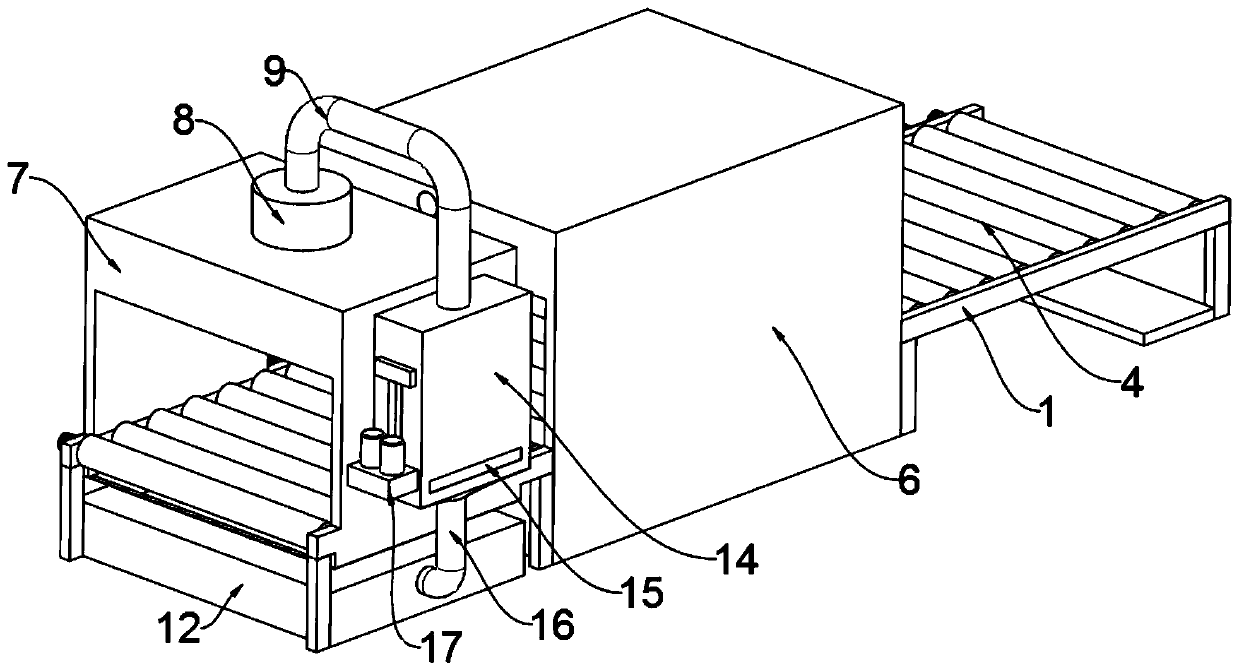

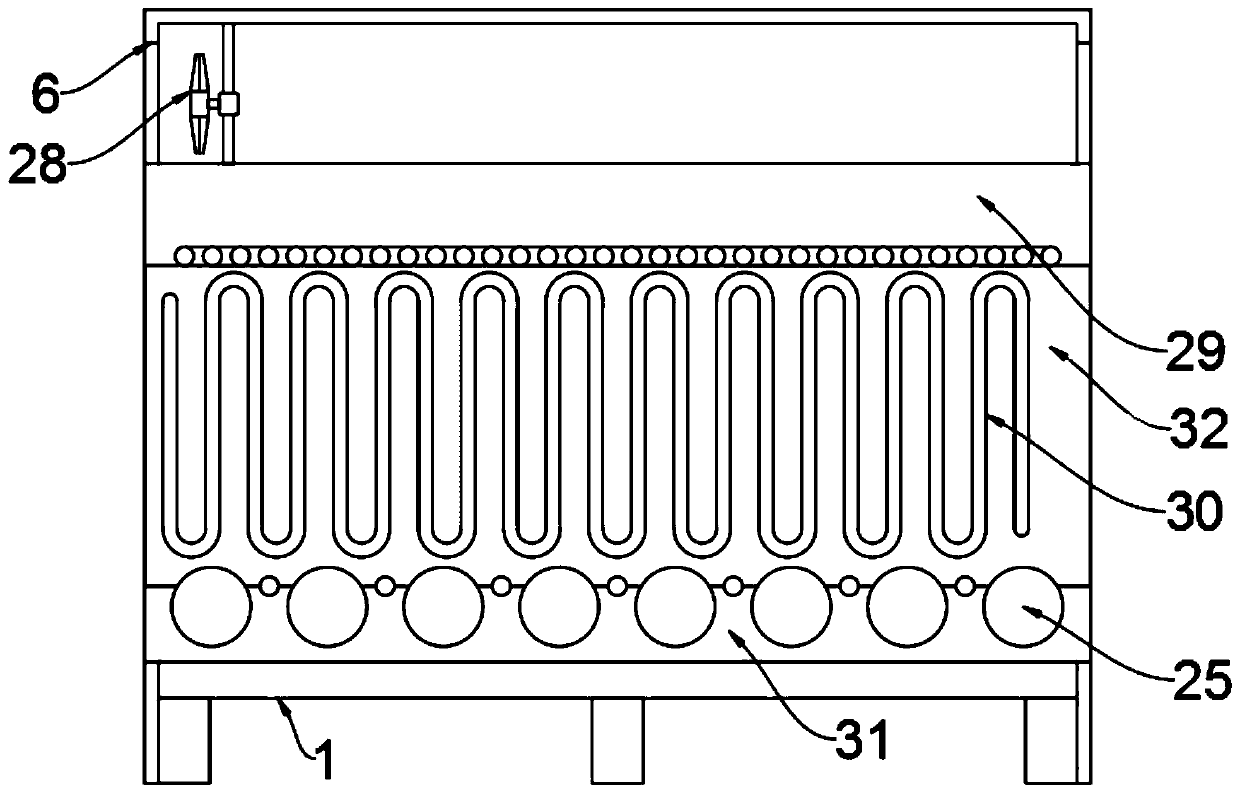

Heat treatment equipment for die steel machining and production

InactiveCN110592345AGood insulation performanceAvoid artificial unluckyFurnace typesHeat treatment furnacesWater vaporWater resources

The invention discloses heat treatment equipment for die steel machining and production, relates to the field of die steel heat treatment, and aims to solve the problem of water resource waste as cooling water generated during the conventional die steel quenching is directly discharged, and meanwhile generated vapor is not collected. A first transferring roller is arranged between roll shaft mounting racks; a belt pulley is arranged at one end of the first transferring roller; an alternating current motor is arranged between the firs transferring roller; a speed reducer is arranged at one endof the alternating current motor; the belt pulley is arranged at one end of a rotating shaft of the speed reducer, and is connected with the belt pulley at one end of the first transferring roller through a belt; a heating box body is arranged on the outer surfaces of the roll shaft mounting racks.

Owner:大冶市飞亚模具材料有限公司

Anti-aging plastic

The invention discloses anti-aging plastic. The anti-aging plastic comprises natural rubber, white oil, calcium sulfate, dioctyl phthalate, flexibilizer, polyphenyl ether, silver oxide, an anti-ultraviolet agent and nano calcium carbonate. The anti-aging plastic comprises, by weight, 20-30 parts of the natural rubber, 2-5 parts of the white oil, 1-3 parts of the calcium sulfate, 3-5 parts of the dioctyl phthalate, 1-3 parts of the flexibilizer, 10-15 parts of polyphenyl ether, 1-5 parts of the silver oxide, 15-25 parts of the anti-ultraviolet agent and 3-8 parts of the nano calcium carbonate. In this way, the anti-aging plastic can be provided. According to the anti-aging plastic, the price is low, the yield is high, the performance is good, the environmental protecting coefficient is high, in the using process, the anti-aging performance is good, and on the premise of guaranteeing of the original plastic performance, the anti-aging performance is optimized.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

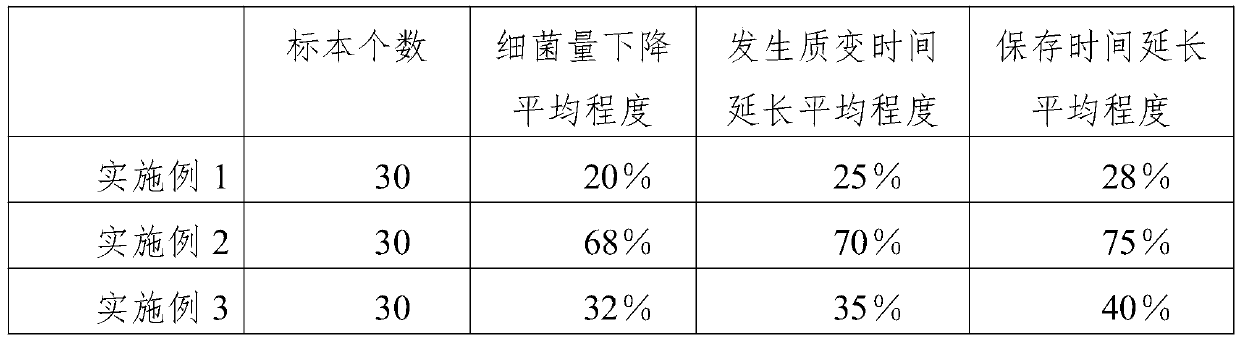

Manufacturing method for ornamental fish-embedded specimen

InactiveCN110934130AOvercome the defects of immersion preservationOvercoming distortionDead animal preservationFisheryNatural state

Embodiments of the invention disclose a manufacturing method for an ornamental fish-embedded specimen, and specifically relates to the technical field of specimen manufacturing. The manufacturing method comprises the following concrete steps: S1, fish treatment; S2, preservative treatment; S3, manufacturing of a soaked specimen; S4, manufacturing of an ecological landscape specimen; and S5, embedding. The manufacturing method provided by the invention is safe and non-toxic and has high environmental protection coefficient; meanwhile, a specimen has real and natural form, and overcomes the problems of distorted and wizened specimen and generation of white spots and bubbles due to incomplete dehydration in traditional embedding of a fish specimen; meanwhile, the fish-embedded specimen manufactured by using the manufacturing method provided by the invention is convenient and visual, can realize 360-degree observation and study, and overcomes the defect of inconvenience in observation of atraditional specimen; meanwhile, fish swims and is lifelike in a soaking liquid, so the form of the fish in a natural state is preserved; the fish-embedded specimen can be preserved for a long time,is convenient to use and store and stable in specimen form, and can be used for a long time after one-time investment; and the maintenance and updating cost of the specimen is greatly reduced.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

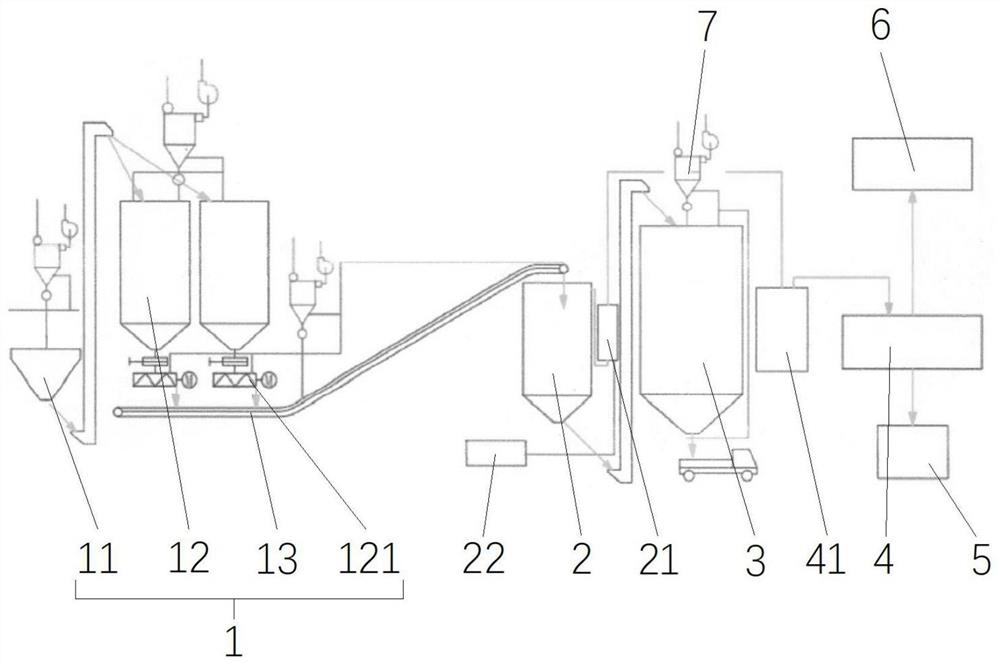

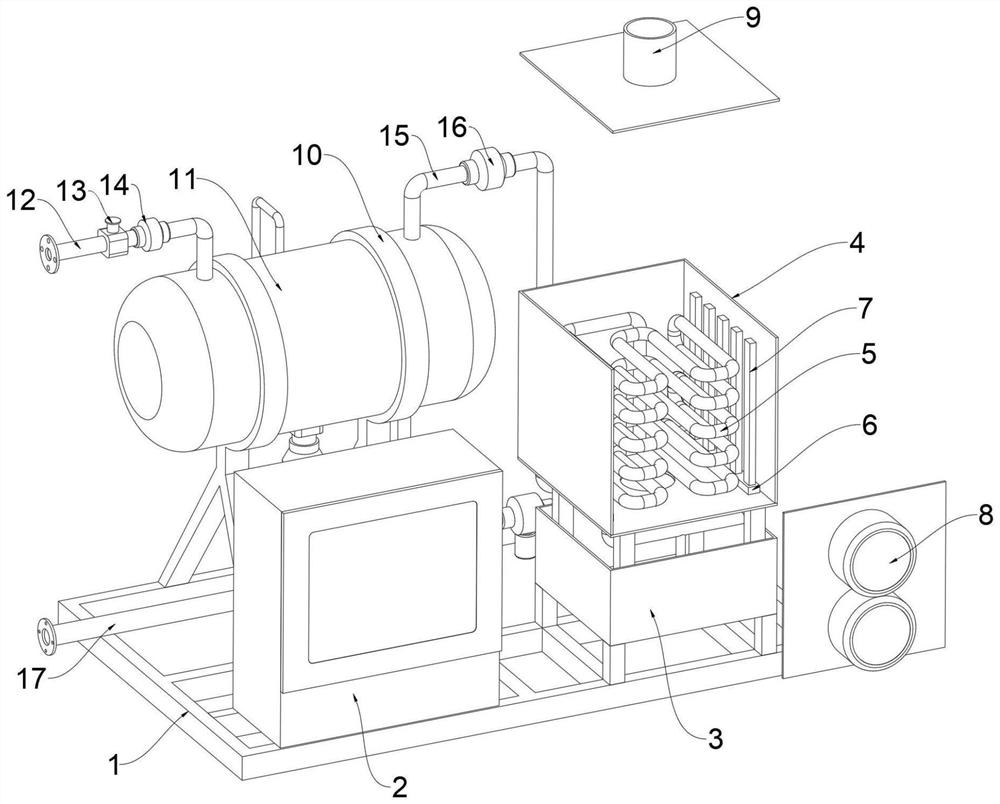

Combined heat and power generation system capable of generating power by utilizing biomass in stepped manner

ActiveCN112646594AImprove pyrolysis efficiencyImprove energy conversion efficiencyChemical industryBiofuelsCogenerationProcess engineering

The invention relates to a combined heat and power generation system capable of generating power by utilizing biomass in a stepped manner. The combined heat and power generation system comprises a raw material processing unit, a biomass pyrolysis and gasification unit, a straw carbon bin, a gas turbine power generation unit and a central control unit. The central control unit is arranged, a preset difference matrix d0, a preset rotating speed matrix W0 and a preset rotating speed adjusting parameter matrix wa0 are arranged in the central control unit, and when a cutter adopts Wi rotating speed to cut straw into straw blocks, a visual detector detects the average block diameter D of the straw blocks and compares D with the corresponding ith preset block diameter Di; the difference value d between the actual block diameter of the straw block and the preset block diameter is calculated, and the rotating speed of the cutter is adjusted by selecting the corresponding preset rotating speed adjusting parameter according to the comparison result, so that different kinds of straw can be effectively cut into straw blocks with the corresponding block diameters, and the pyrolysis efficiency of the straw blocks is improved; and the energy conversion efficiency of the system is improved.

Owner:SHEXIAN QINGZHANG CEMENT MFG CO LTD

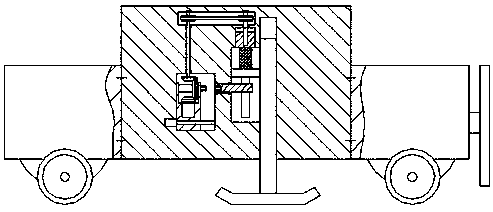

Environment-friendly glass device

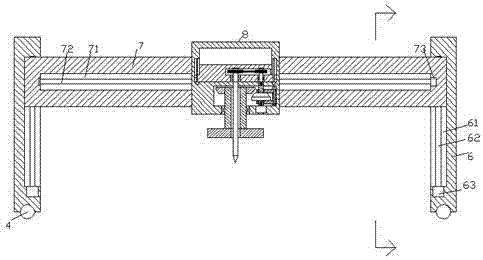

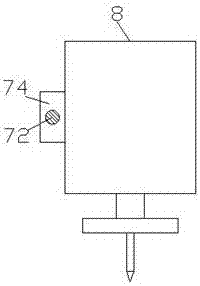

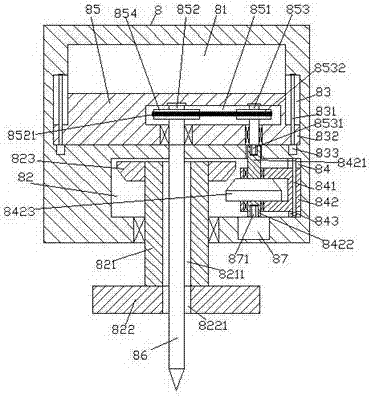

ActiveCN107486949AAvoid injuryAvoid pollutionWorking accessoriesStone-like material working toolsEngineeringChassis

The invention discloses an environment-friendly glass device used for conducting tapping on glass. The environment-friendly glass device comprises a chassis used for installing glass and a fixed frame which is fixedly installed above the chassis through a bracket, a dust sucking device is arranged on the right end face of the bracket, the left side of the dust sucking device is provided with a dust sucking pipe which penetrates through the bracket, a middle end hole is formed in the middle end of the fixed frame, a middle end frame is fixedly installed in the middle end hole, and the upper end of the middle end frame extends upwards; and upper side frames are oppositely installed on the two sides of the upper end of the middle end frame, a vertical arm is fixedly installed between each upper side frame and the fixed frame, an upper sliding hole, a middle sliding hole and a lower sliding hole are formed in the middle end frame, a through groove is formed between the middle sliding hole and the upper sliding hole, a through groove is formed between the middle sliding hole and the lower sliding hole, and a through cavity which communicates with the outside is formed in the middle end of the lower end wall of the lower sliding hole.

Owner:江苏长欣车辆装备有限公司

Improved environmental-protection glass device

InactiveCN107856196AAvoid injuryAvoid pollutionWorking accessoriesStone-like material working toolsEngineeringChassis

The invention discloses an improved environment-friendly glass device, which is used for opening holes in the glass, including a chassis for installing the glass and a fixed frame fixed above the chassis through a bracket, and a dust suction device is arranged on the right end surface of the bracket. , the left side of the dust collection device is provided with a dust suction pipe passing through the bracket, a middle end hole is arranged at the middle end of the solid frame, a middle end frame is fixedly installed in the middle end hole, the upper end of the middle end frame expands upwards, and the middle end The upper side frame is installed opposite to the two sides of the upper end of the frame, and the vertical arm is fixedly installed between the upper side frame and the fixed frame. Intercommunication grooves are arranged between the sliding holes, and a through cavity communicating with the outside is arranged at the middle end of the lower end wall of the sliding holes.

Owner:孙卫香

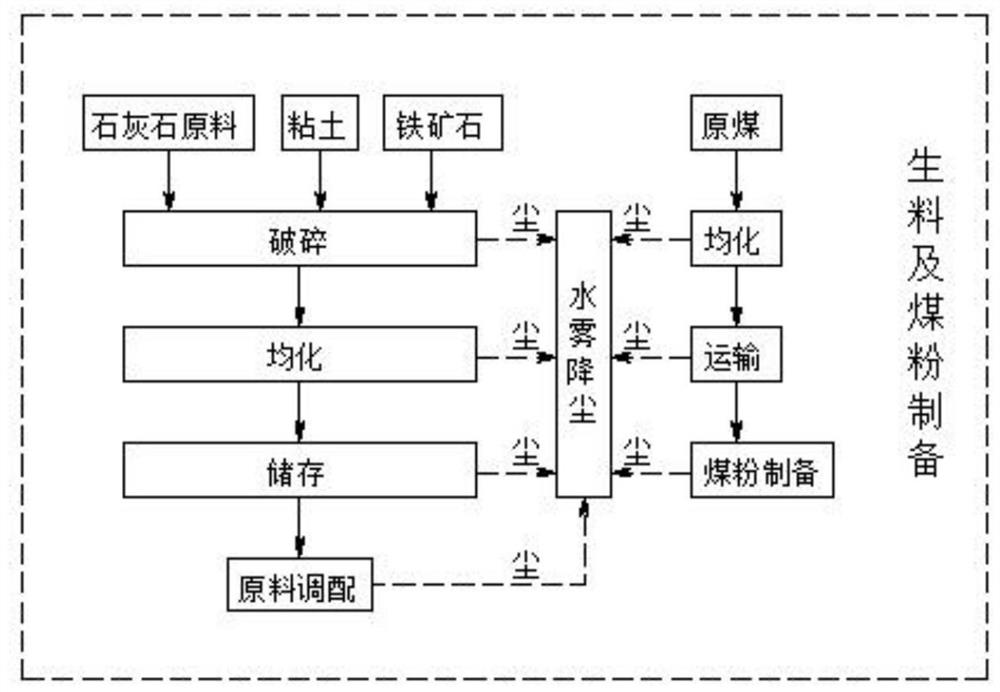

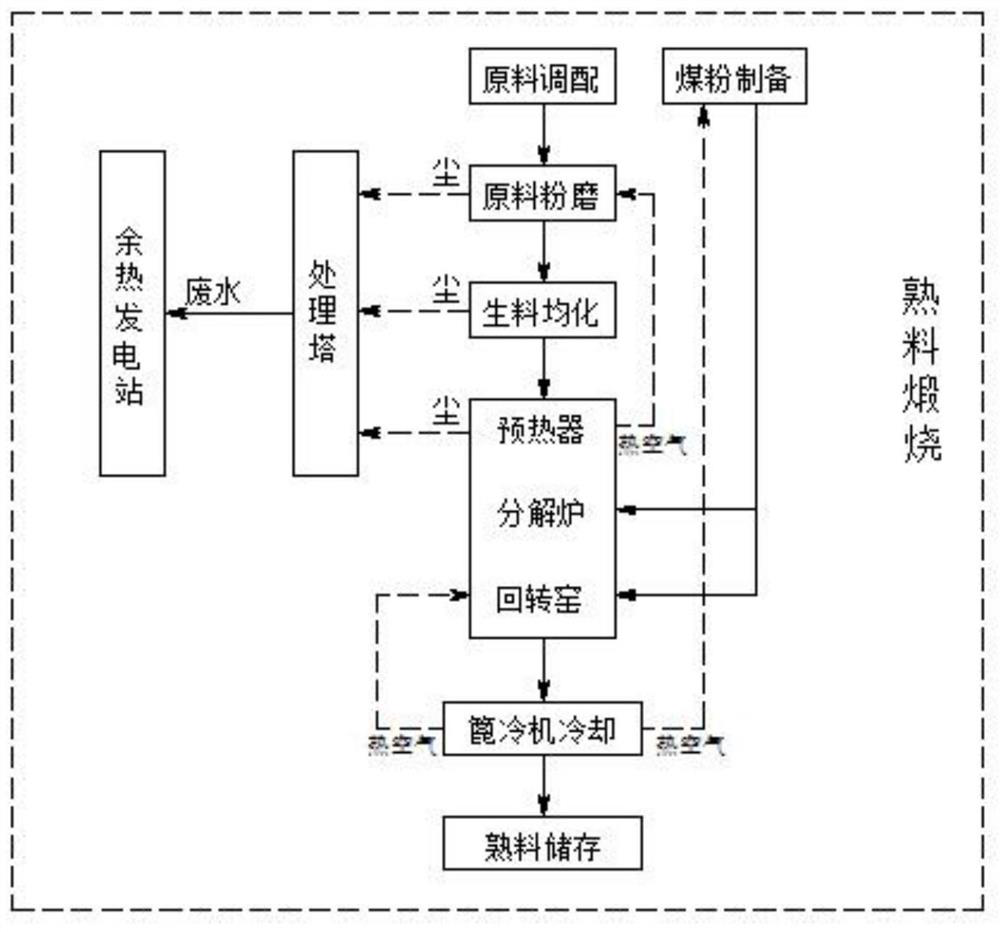

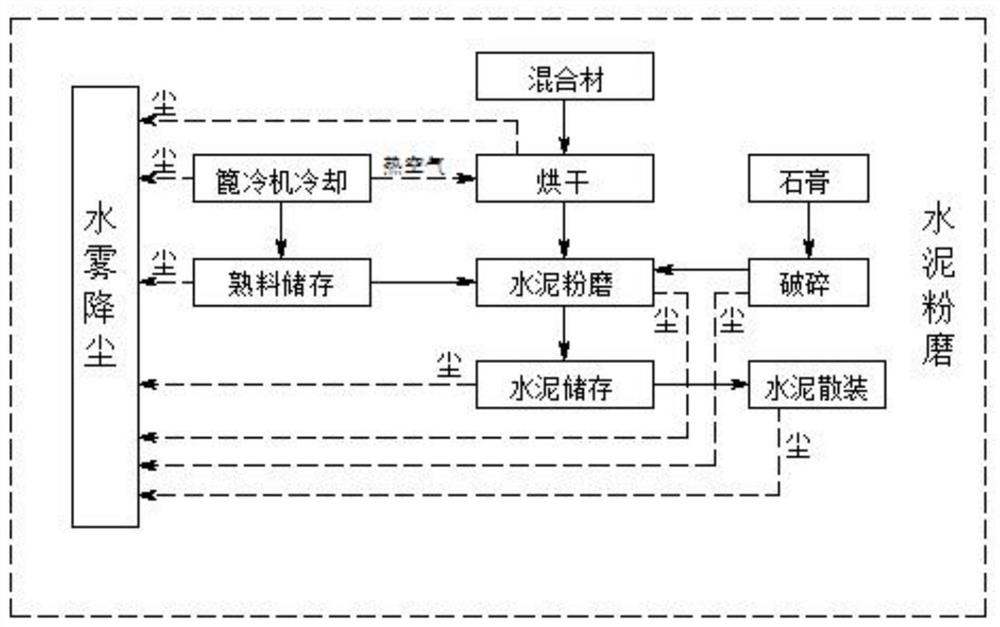

Industrial waste residue masonry cement based on biomass fuel calcined clinker and preparation method thereof

The invention discloses industrial waste residue masonry cement based on biomass fuel calcined clinker and a preparation method of the industrial waste residue masonry cement, the preparation method comprises raw material and pulverized coal preparation dust removal, clinker calcination dust removal and cement grinding dust removal, and the cement production sequence is raw material and pulverizedcoal preparation, clinker calcination and cement grinding. The raw material and pulverized coal preparation dust removal and the cement grinding dust removal are carried out by adopting a water mistdust removal method, the clinker calcination storage adopts a treatment tower to remove dust and gas, and high-temperature air is introduced into a waste heat power station to realize the recycling ofheat. Dust generated in the production process of cement raw materials, clinker and finished products is comprehensively eliminated, dust pollution is reduced, the body health of workers is maintained, heat generated in the clinker production process is effectively recycled, energy conservation and environmental protection are achieved, and pollutants can be reduced.

Owner:安徽枞阳海螺水泥股份有限公司

Environment-friendly big data monitoring terminal

PendingCN112378825AHarm reductionReduce pollution factorParticle suspension analysisProcess engineeringVideo recording

The invention discloses an environment-friendly big data monitoring terminal, which comprises a memory and a processor, wherein the processor is connected with the memory; the memory is used for storing executable instructions of the processor; the processor is used for calling an executable instruction in the memory so as to report a dust distribution area and a dust distribution amount in a factory by using the environment-friendly big data monitoring mechanism, and the environment-friendly big data monitoring mechanism comprises pinhole video recording equipment which is arranged on a ceiling of the factory and is used for acquiring a video recording image below the factory, and the processor is used for providing data information according to the environment-friendly big data detectionmechanism. Through establishment of the environment-friendly big data monitoring terminal, harm of dust to the body of a worker can be greatly reduced, dust distribution information in a factory is monitored in real time, and dust is collected or subjected to dust falling treatment in time, so that the dust pollution coefficient in the factory is greatly reduced, and the environment-friendly coefficient in the factory is greatly increased.

Owner:江苏中润普达环境大数据有限公司

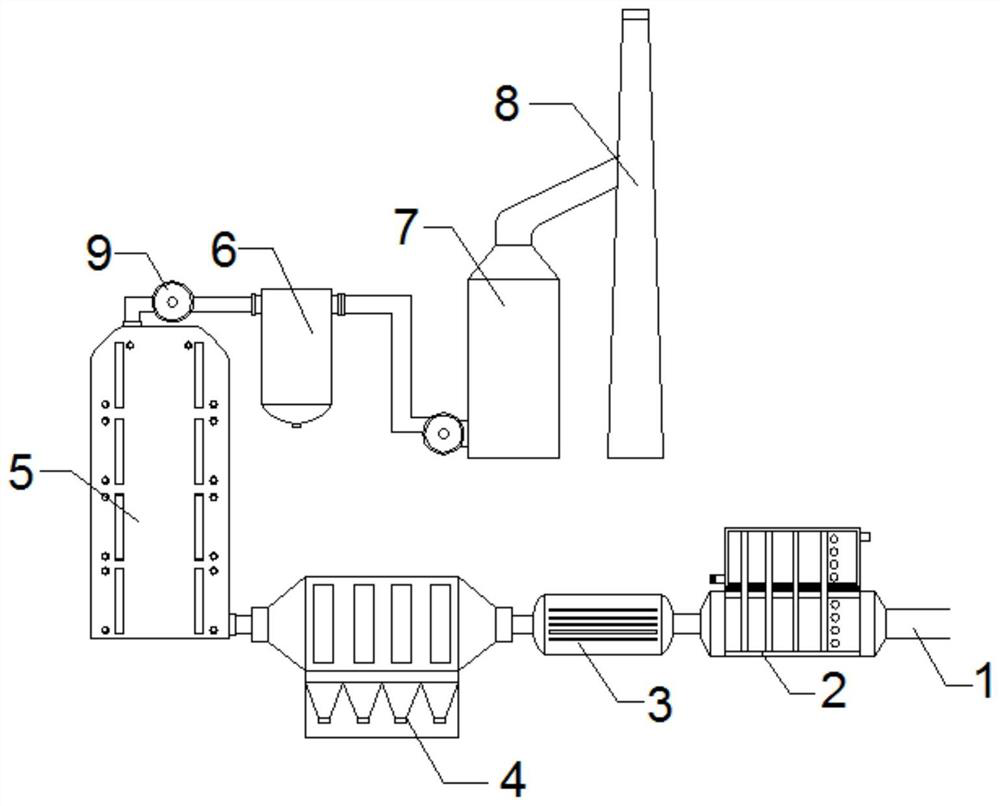

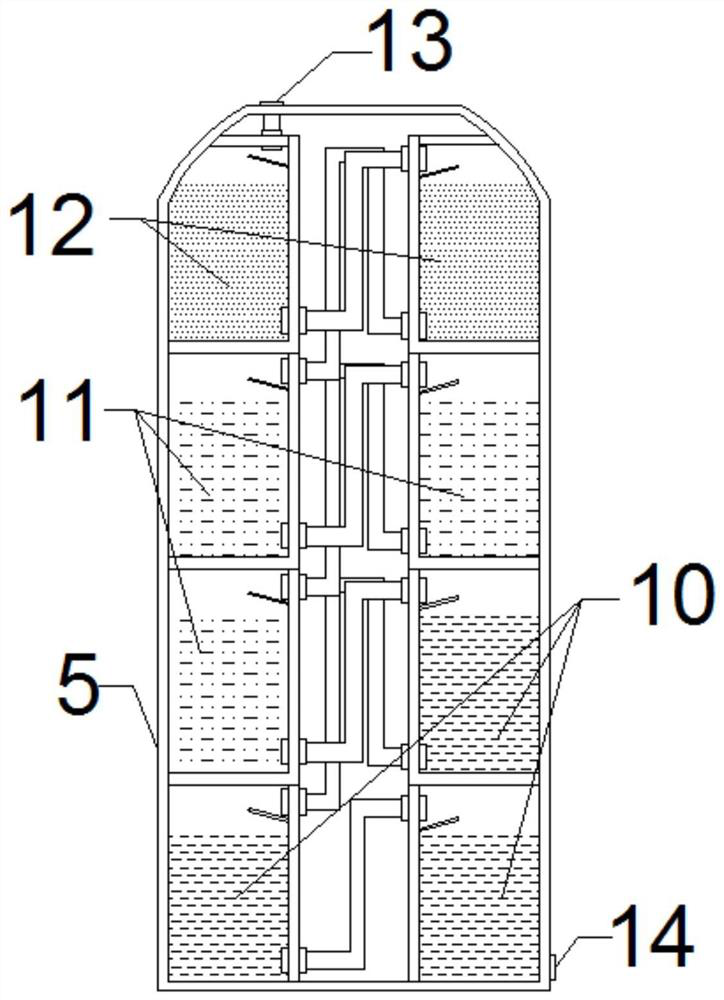

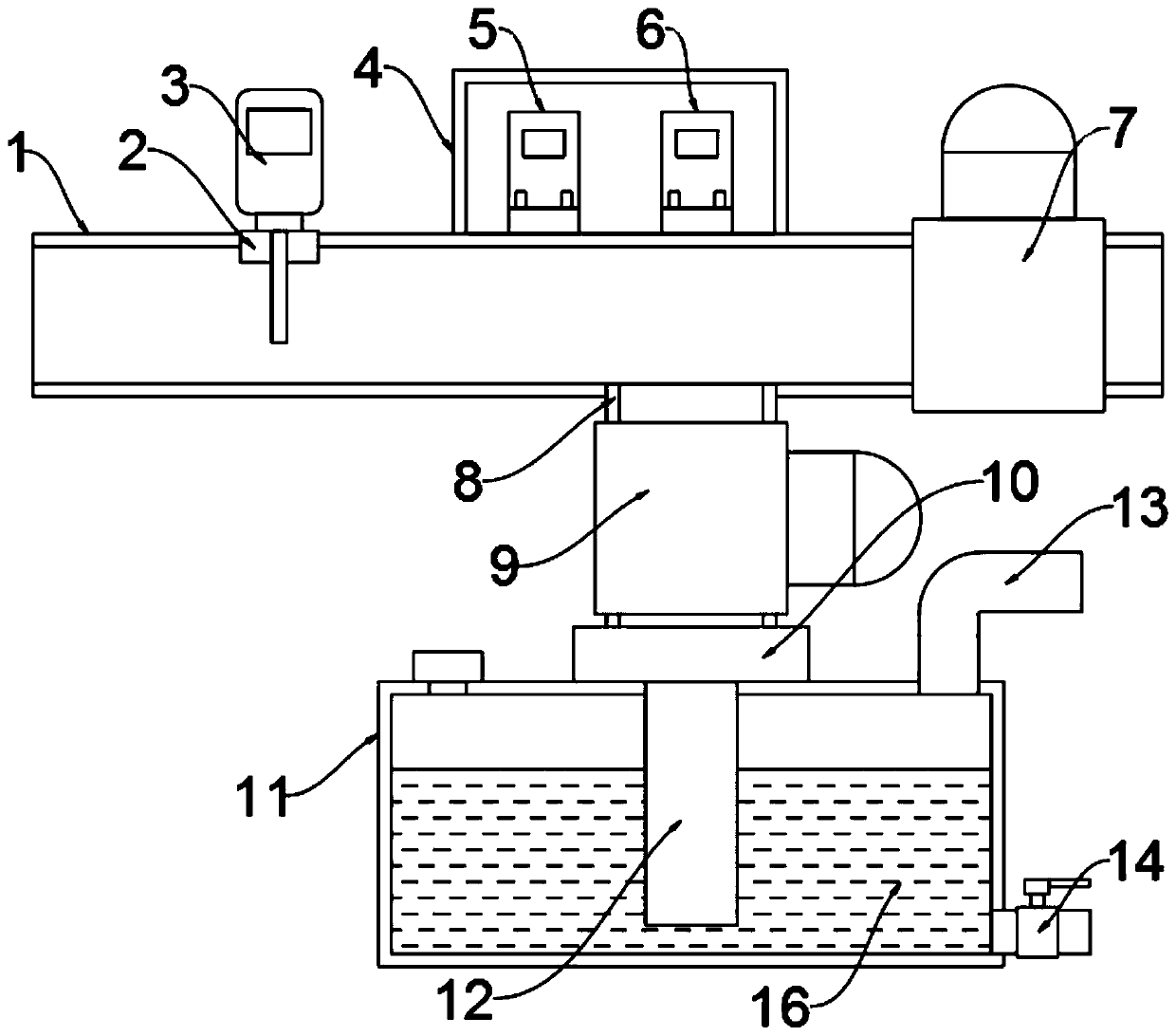

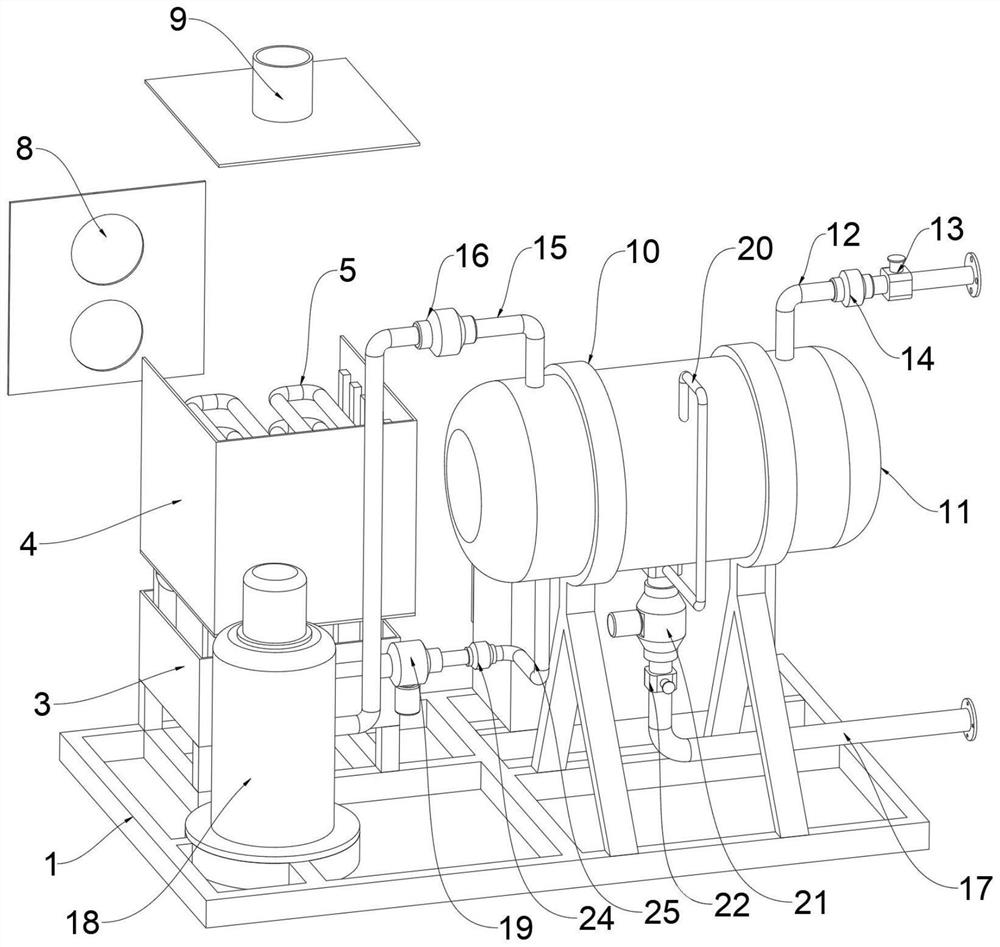

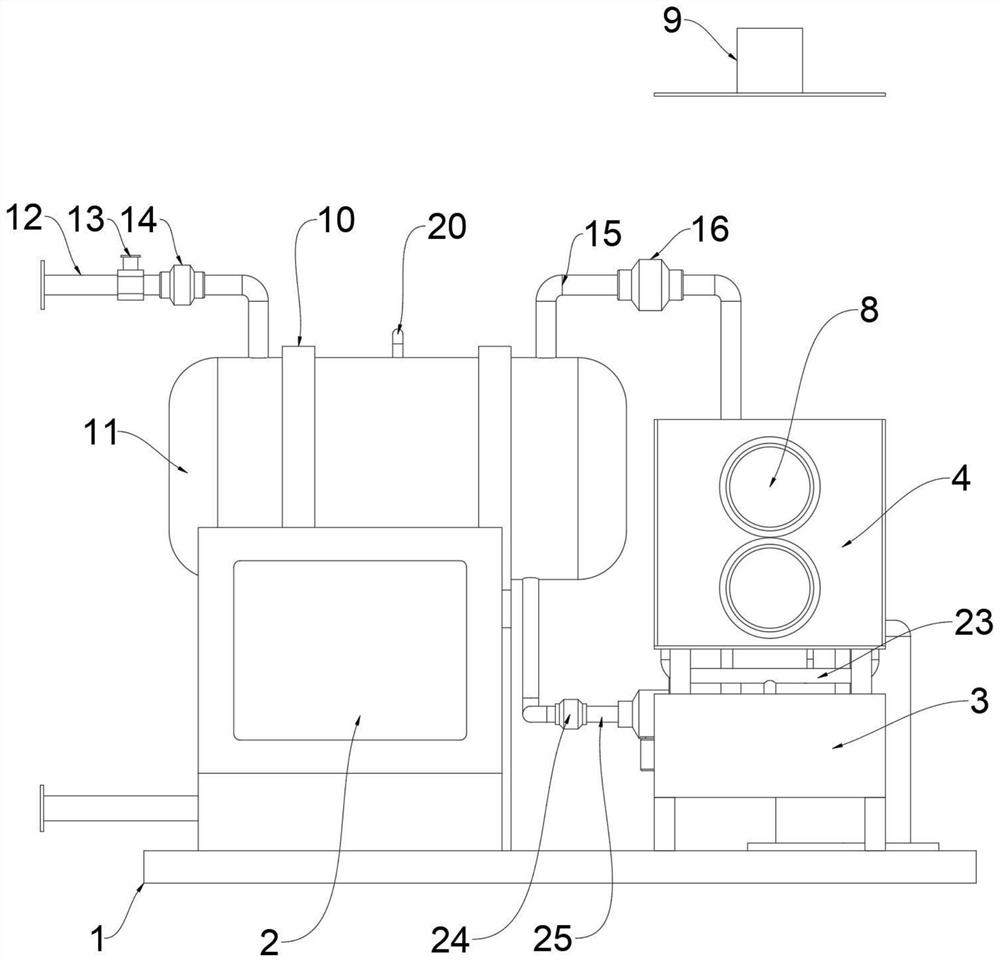

Exhaust gas recovery system capable of reducing condensate

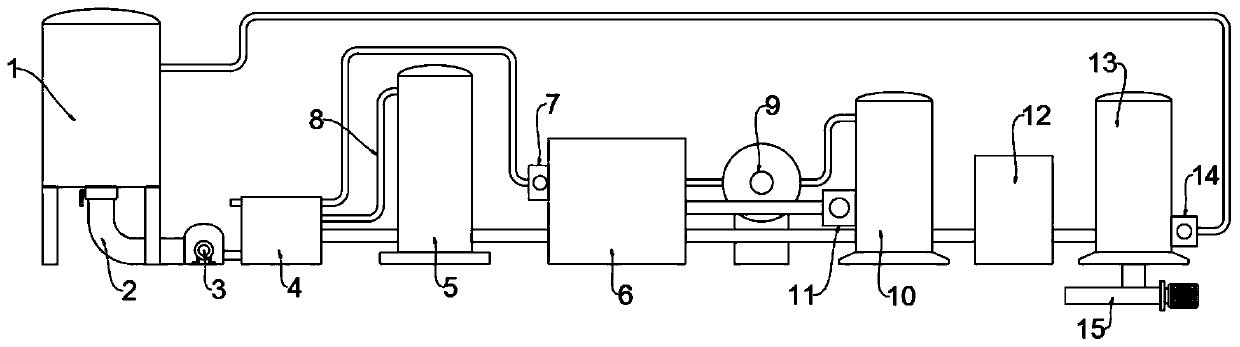

PendingCN111672287AImprove environmental protection factorIncrease diversityGas treatmentDispersed particle separationWater vaporExhaust gas emissions

The invention discloses an exhaust gas recovery system capable of reducing condensate. The system comprises a smoke pipe, a smoke treatment tank and a primary treatment chamber, a smoke exhaust end ofthe smoke pipe is connected with a waste heat recoverer through a flange, a smoke outlet end of the waste heat recoverer is connected with a water cooling flue, a gas outlet end of the water coolingflue is connected with a bag-type dust collector, a smoke treatment tank is arranged on one side of the bag-type dust collector, a gas inlet nozzle is formed in the bottom of one side of the smoke treatment tank, and a gas outlet nozzle is formed in the top of the smoke treatment tank. According to the waste gas recovery system, multi-stage waste removal treatment is utilized, dust removal and dehydration treatment is carried out on waste gas, condensate and water vapor are reduced, and multi-stage cooling and dust falling treatment is carried out through the carbon dioxide absorbent liquid, the desulfurizing agent liquid and the denitrifying agent liquid while carbon dioxide, sulfur and nitrate are removed, so that the environment-friendly coefficient of the waste gas treated by the wastegas recovery system is higher when the waste gas is discharged.

Owner:潮州市中乾环境科技有限公司

An environmental protection dust removal equipment

ActiveCN107116462BReduce investmentReduce manufacturing costGrinding drivesLapping machinesDust controlScrew joint

Owner:JIANGSU XINYE HEAVY IND

Office garbage crushing treatment device

The invention discloses an office garbage crushing treatment device which comprises a base. A sliding groove is formed in the upper surface of the base, a drawer box is connected to the inner wall ofthe sliding groove in a clamping mode, and hand pulling grooves are formed in the outer surface of the drawer box. A crushing box is fixedly connected to the upper surface of the base, a rotating motor is fixedly connected to the upper surface of the base, and a motor box is fixedly connected to the upper surface of the base. A first gear is fixedly connected to the output end of the rotating motor, a first rolling bearing is fixed inside the crushing box, and a second rolling bearing is fixedly connected to the end, away from the first rolling bearing, of the inner part of the crushing box. Afirst transmission shaft is fixedly connected to the inner wall of the first rolling bearing, an active crushing column is fixedly connected to the outer surface of the first transmission shaft, thefirst transmission shaft penetrates through the active crushing column and is fixedly connected to the inner wall of the second rolling bearing. The office garbage treatment device has the advantagesof high crushing speed, thorough crushing and low noise.

Owner:芜湖寅越信息科技有限公司

Flue gas monitoring alarm device

PendingCN110827489APrevent leakageAvoid failureCombination devicesPipeline systemsFlue gasProcess engineering

The invention discloses a flue gas monitoring alarm device, relates to the field of flue gas monitoring, and aims to solve the problems that an existing monitoring device can only monitor data and give an alarm and cannot carry out emergency measures, and partial flue gas leakage is easily caused. A detector mounting seat is arranged on the outer surface of a flue gas circulation pipeline; a PM2.5detector is fixedly mounted on the detector mounting seat; the detection end of the PM2.5 detector is arranged in the flue gas circulation pipeline; a control box body is arranged on the outer surface of the upper end of the flue gas circulation pipeline, a first relay and a second relay are arranged in the control box body, the PM2.5 detector has a buzzing function, a contact of the first relayis normally opened, and a contact of the second relay is normally closed.

Owner:海安嘉臣环境科技有限公司

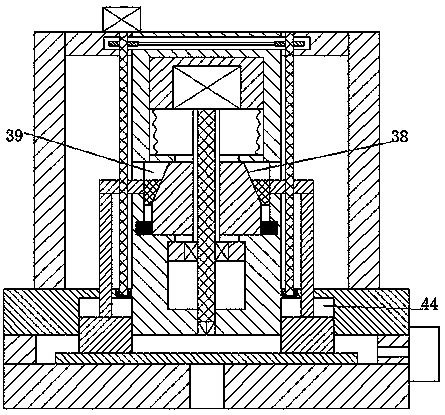

Practical type environment-friendly grinding device

InactiveCN107855845AAvoid injuryEffective isolationGrinding carriagesGrinding drivesMechanical engineeringExtended side

The invention discloses a practical environment-friendly grinding equipment, which is used for grinding steel plates. It includes a bottom support for installing steel plates and a card seat fixed and installed above the bottom support through a bracket. A central hole is arranged in the center of the card seat. A central frame is fixedly installed in the central hole, the upper end of the central frame is extended upwards, and top frames are installed on both sides of the upper end of the central frame, a vertical frame is fixedly installed between the top frame and the card seat, and an upper sliding cavity is arranged in the central frame , the middle sliding cavity and the lower sliding cavity, there are connection grooves between the middle sliding cavity, the upper sliding cavity and the lower sliding cavity, the upper sliding frame can be installed in the upper sliding cavity, and the upper sliding frame can be installed in the lower sliding cavity. The lower frame and the middle sliding cavity are equipped with sliding blocks that are equal to each other and can move left and right.

Owner:毛杰

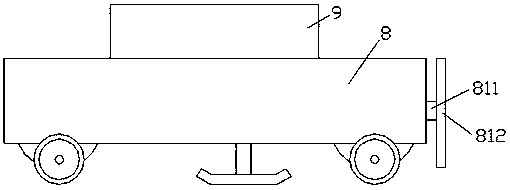

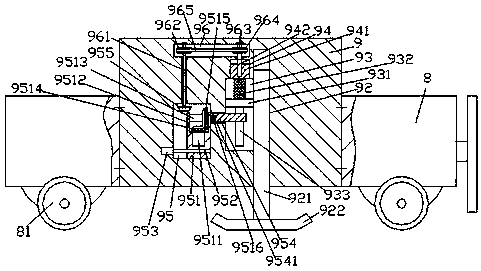

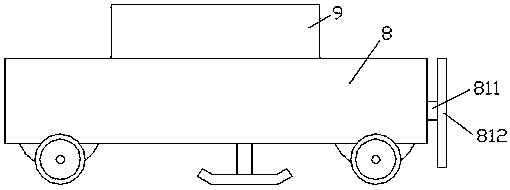

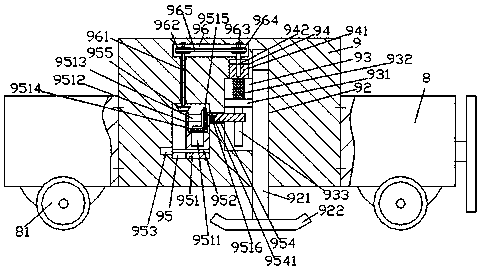

Environment-friendly garbage rolling compaction device

InactiveCN108069173AImprove efficiencyLow costRefuse receptaclesRefuse vehiclesMobile vehicleEngineering

The invention discloses an environment-friendly garbage rolling compaction device. The environment-friendly garbage rolling compaction device comprises a moving vehicle body and a garbage rolling compaction body fixedly installed in the moving vehicle body. The right end surface of the moving vehicle body is fixedly provided with a push plate through a transverse arm. A through opening which extending up and down is arranged in the push plate, and the left side and the right side of the through opening communicate. A first sliding connecting groove which extends downwards and penetrates through the bottom end surface of the garbage rolling compaction body is arranged in the garbage rolling compaction body. The inner wall of the left side of the first sliding connecting groove is provided with a first change groove in a communicating mode. A guide groove is formed in the top wall in the first change groove in a communicating mode. A second change groove extending towards the left side is formed in the inner wall of the part, at the upper side of the guide groove, of the garbage rolling compaction body. A dispatch cavity is formed in the inner wall of the part, at the left side of the first change groove, of the garbage rolling compaction body. The tail side of the top of the dispatch cavity is located under the extending section of the left side of the first change groove. The environment-friendly garbage rolling compaction device is simple in structure, convenient to operate, and capable of meeting different garbage rolling compaction work requirements and improving garbagerolling compaction quality. Meanwhile, the work efficiency is greatly improved, and the work cost is reduced.

Owner:佛山市庐米文化传播有限公司

Novel environmental-protection glass device

InactiveCN107856197AAvoid injuryAvoid pollutionWorking accessoriesStone-like material working toolsChassisEngineering

The invention discloses a new type of environment-friendly glass device, which is used for opening holes in the glass, including a chassis for installing the glass and a fixed frame fixed above the chassis through a bracket, and a dust suction device is arranged on the right end surface of the bracket , the left side of the dust collection device is provided with a dust suction pipe passing through the bracket, a middle end hole is arranged at the middle end of the solid frame, a middle end frame is fixedly installed in the middle end hole, the upper end of the middle end frame expands upwards, and the middle end The upper side frame is installed opposite to the two sides of the upper end of the frame, and the vertical arm is fixedly installed between the upper side frame and the fixed frame. Intercommunication grooves are arranged between the sliding holes, and a through cavity communicating with the outside is arranged at the middle end of the lower end wall of the sliding holes.

Owner:孙卫香

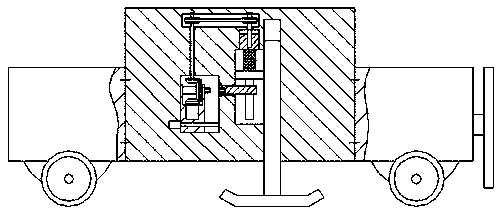

Environment-friendly garbage grinding device

The invention discloses an environment-friendly garbage grinding device. The environment-friendly garbage grinding device comprises a walking car body, and a garbage grinding body fixedly mounted in the walking car body; a push plate is fixedly mounted on the right end surface of the walking car body through a transverse arm; a through port, extending up and down and communicating left and right,is formed in the push plate; a first sliding groove, extending downwards and penetrating through the bottom end surface of the garbage grinding body, is formed in the garbage grinding body; a first change groove communicates to the inner wall of the left side of the first sliding groove; a guide groove communicates into the inner top wall of the first change groove; a second change groove, extending to the left side, is formed in the inner wall body of the garbage grinding body on the upper side of the guide groove; a dispatching cavity is formed in the inner wall body of the garbage grindingbody on the left side of the first change groove; and the tail side of the top of the dispatching cavity is positioned below the left side extension section of the first change groove. The environment-friendly garbage grinding device is simple in structure and convenient to operate, can satisfy different garbage grinding demands, improves the garbage grinding quality, meanwhile, greatly improves the working efficiency, and reduces the working cost.

Owner:盐城旷智科技有限公司

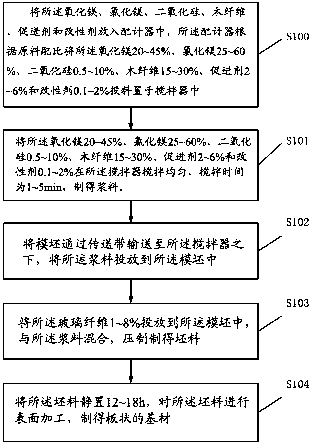

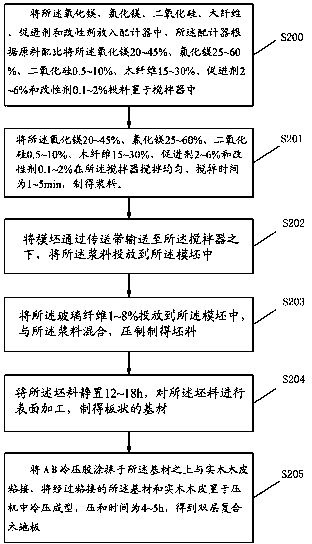

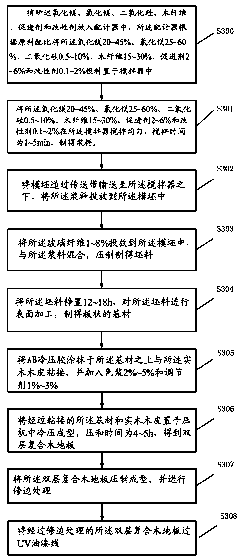

A double-layer composite wood floor and its preparation method

The invention discloses a double-layer composite wood floor. The double-layer composite wood floor comprises a base material and a real-wood veneer which is 0.6mm to 5.0mm in thickness; the base material is bonded with the real-wood veneer by being coated with AB cold-pressing glue, the bonded base material and real-wood veneer is subjected to cold-pressing molding in a pressing machine, wherein the pressing time is 4-5 hours, so as to obtain the double-layer composite wood floor; the base material comprises the following primary raw materials in percentage by weight: 20-40% of magnesium oxide, 25-60% of magnesium chloride, 0.5-10% of silicon dioxide, 15-30% of wood fiber and 1-8% of glass fiber. Correspondingly, the invention also discloses a preparation method of the double-layer composite wood floor. The double-layer composite wood floor provided by the invention not only is environmental-friendly, non-toxic, odorless, tasteless, non-radioactive, and does not have any harmful effects to human bodies and animals, but also has the following advantages of low cost, fireproof and waterproof property, insect prevention and bacteria inhibition and heat resistance and reducing noise and the like.

Owner:何晓龙

Substrate for soilless seedling cultivation of plum vegetables

InactiveCN103739400BMeet actual needsEasy to grow seedlingsFertilizer mixturesOrganic fertilizerHigh survival rate

The invention discloses a substrate for soilless seedling cultivation of plum vegetables. The substrate contains leaf dregs of plum vegetables, which are decomposed and used as organic fertilizers. Sterilize and provide nutrients to obtain a loose, breathable, water- and fertilizer-retaining substrate, and compared with traditional soil seedlings for plum vegetables, it has the advantages of less pests and diseases, low cost, high survival rate, strong disease resistance, and high yield; Utilizing the plum vegetable leaf dregs and tea dregs can also realize waste utilization, reduce costs, and have strong economic efficiency.

Owner:谭飞鸿

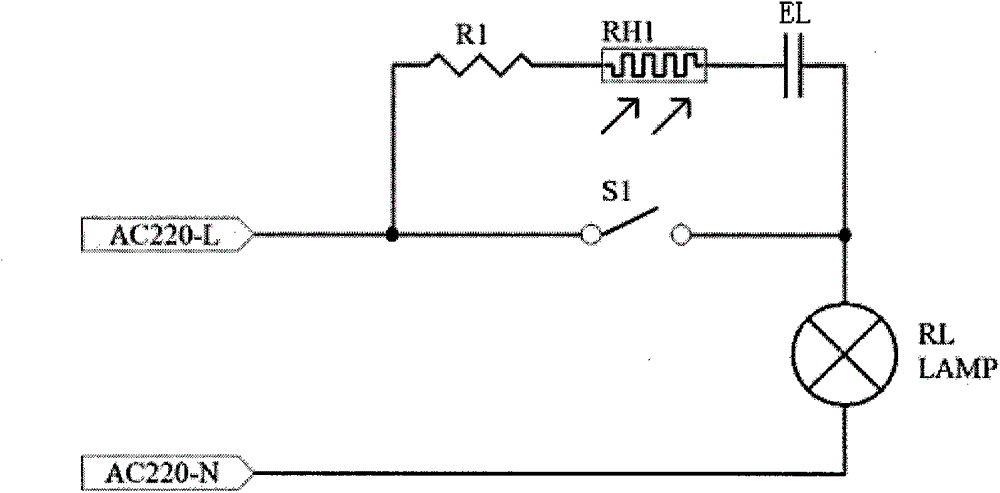

Novel switch capable of emitting light

InactiveCN104681327ANo adverse effectsReduce power consumptionElectric switchesElectricityEngineering

The invention provides a novel switch capable of emitting light. The novel switch comprises a switch button, a light source, a resistor and a light sensitive element, wherein a light emitting element, the resistor and the light sensitive element are connected in series and then are connected with the switch button in parallel; the light emitting element is an electroluminescent film. The electroluminescent film is used as the light emitting element, so the novel switch provided by the invention has the advantages of low power consumption, no heat generation, no ultraviolet ray generation, no radiation, no adverse influence on a human body, high environment-friendly coefficient and simple structure; the novel switch can be used as a night lamp for illumination while the novel switch has an illuminating indication.

Owner:丁林昌

An environmentally friendly glass device

ActiveCN107486949BAvoid injuryAvoid pollutionWorking accessoriesStone-like material working toolsFixed frameEngineering

The invention discloses an environment-friendly glass device used for conducting tapping on glass. The environment-friendly glass device comprises a chassis used for installing glass and a fixed frame which is fixedly installed above the chassis through a bracket, a dust sucking device is arranged on the right end face of the bracket, the left side of the dust sucking device is provided with a dust sucking pipe which penetrates through the bracket, a middle end hole is formed in the middle end of the fixed frame, a middle end frame is fixedly installed in the middle end hole, and the upper end of the middle end frame extends upwards; and upper side frames are oppositely installed on the two sides of the upper end of the middle end frame, a vertical arm is fixedly installed between each upper side frame and the fixed frame, an upper sliding hole, a middle sliding hole and a lower sliding hole are formed in the middle end frame, a through groove is formed between the middle sliding hole and the upper sliding hole, a through groove is formed between the middle sliding hole and the lower sliding hole, and a through cavity which communicates with the outside is formed in the middle end of the lower end wall of the lower sliding hole.

Owner:江苏长欣车辆装备有限公司

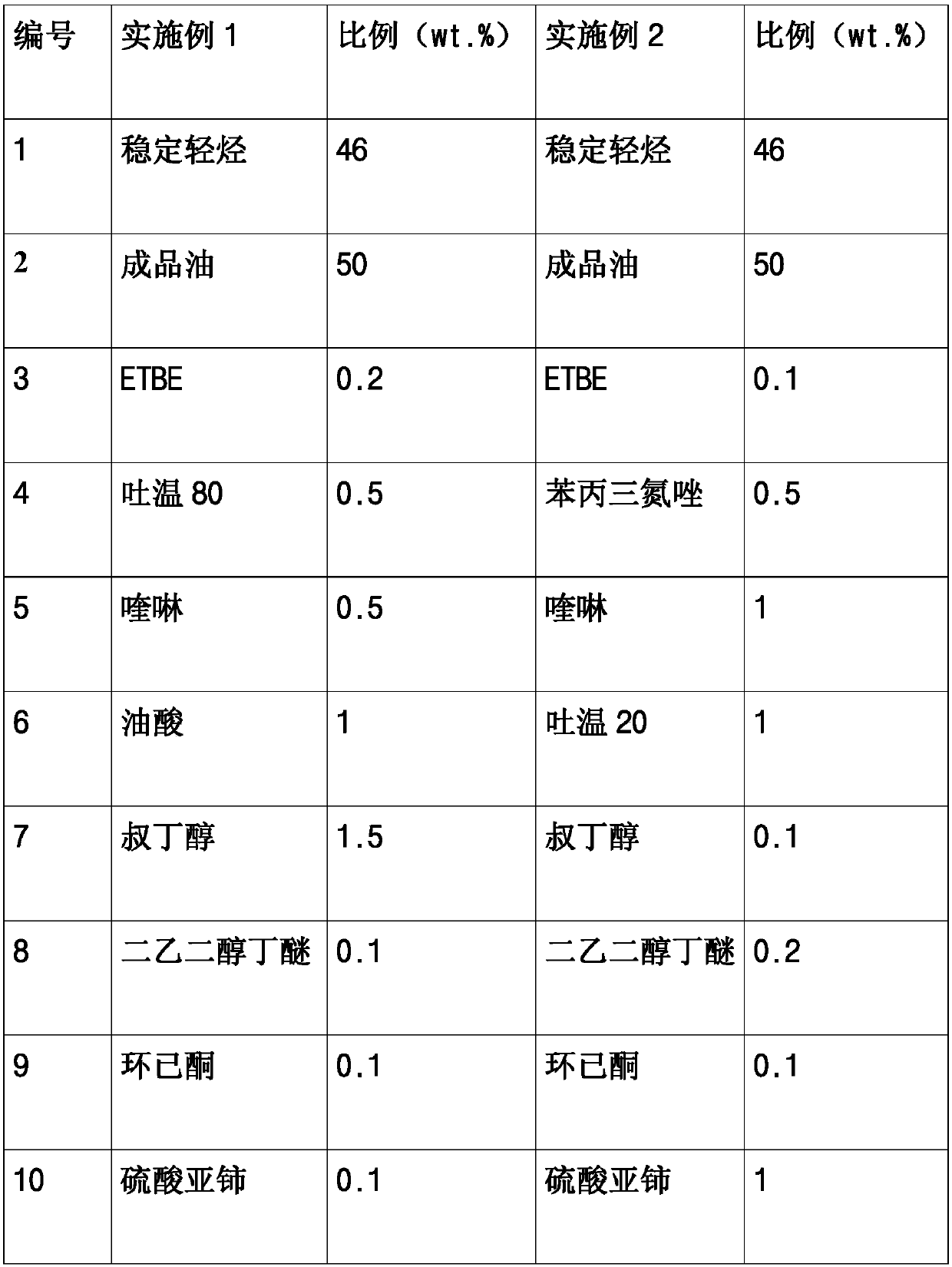

High clean national standard gasoline

InactiveCN109628166AReduce the amount requiredGuarantee the feasibility of implementationLiquid carbonaceous fuelsFuel additivesGasoline fuelFuel oil

The invention relates to a novel clean gasoline fuel. The fuel contains 46% of natural gasoline, 4% of an additive and 5% of national standard gasoline. According to the novel clean fuel, the naturalgasoline participation amount is large, layering does not occur in use, air-resistance can be avoided, power is strong, corrosivity to metal does not exist, the swelling property to an engine sealingring does not exist, a vehicle engine does not need to be changed, and the engine is easy to start in a low temperature state in use. By means of detection, the national vehicle fuel oil standards arecompletely met, and discharge is greatly superior to national related standards.

Owner:GUOHAO BEIJING NEW ENERGY TECH DEV CO LTD

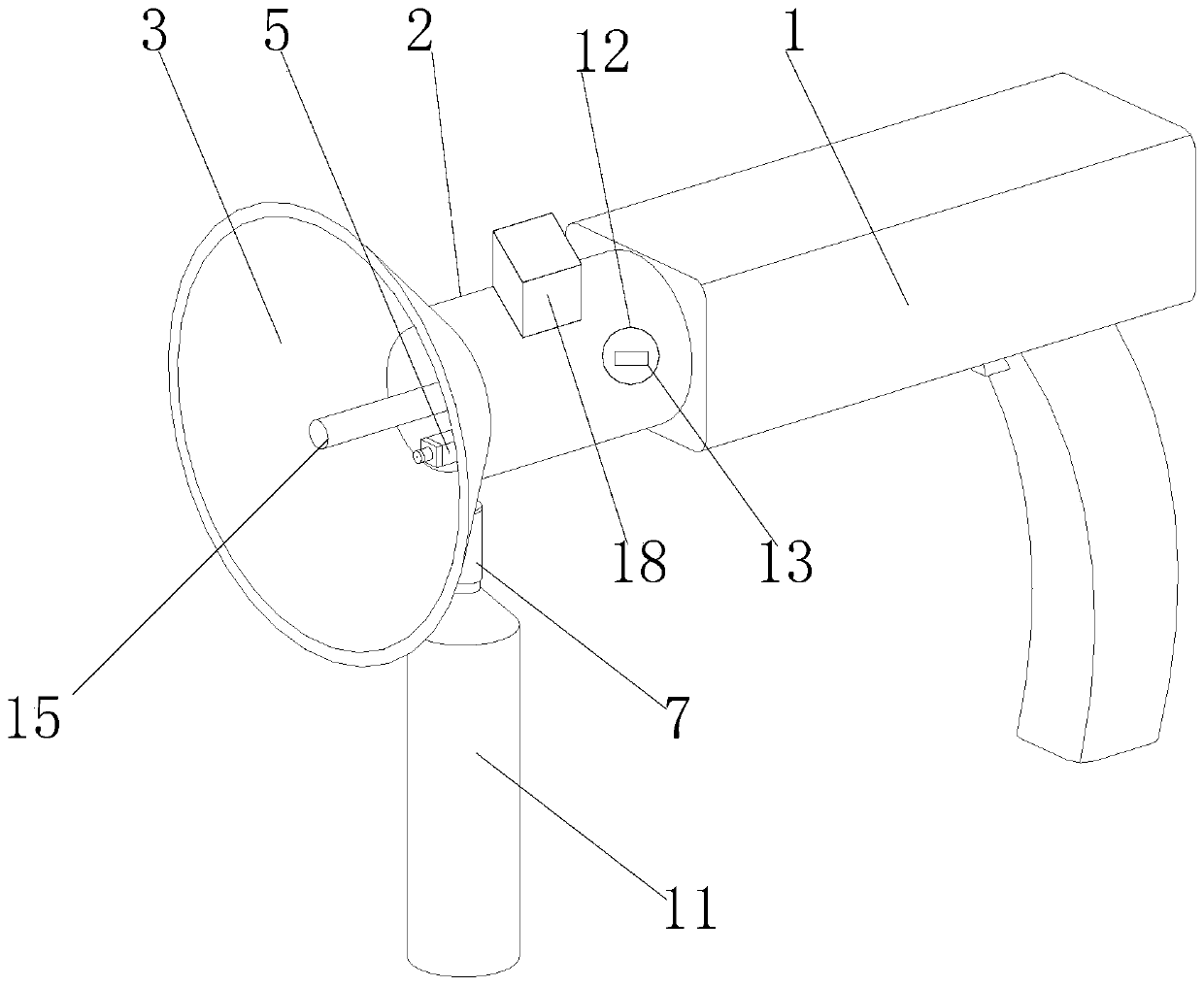

Novel dust-free environmental-friendly electric hammer

InactiveCN111515905AImprove dust removal efficiencyReduce manufacturing costPortable percussive toolsMaintainance and safety accessoriesEngineering

The invention relates to the technical field of dust prevention of electric hammers and discloses a novel dust-free environmental-friendly electric hammer. The novel dust-free environmental-friendly electric hammer comprises an electric hammer body, wherein a rotating shoulder is arranged at the front end of the electric hammer body, a connecting drum is connected outside the rotating shoulder ina sleeving manner, a transparent dustproof hood is fixedly mounted at the front end of the connecting drum, a round through hole is formed in the bottom of the connecting drum, a water pipe is fixedlymounted at the bottom of the round through hole, an atomizing device located in the connecting drum is fixedly mounted on the top of the water pipe, a flow guiding device is fixedly mounted at the bottom of the water pipe, a power-assisting pipe fixedly connected to the bottom of the connecting drum is fixedly connected outside the flow guiding device in a sleeving manner, an extrusion device isfixedly mounted on the outer surface of the power-assisting pipe, a bayonet is fixedly mounted at the bottom of the flow guiding pipe, a drainage hose is connected to the inner side of the bayonet ina clamping manner, a drainage ball is fixedly connected to the lower end of the drainage hose, and a water tank is fixedly connected to a position at the bottom of the outer surface of the flow guiding pipe in a sleeving manner. The novel dust-free environmental-friendly electric hammer solves the problems that an existing novel dust-free environmental-friendly electric hammer is relatively complex in structure and high in production cost, and the dust collecting effect is not ideal and the like.

Owner:杭州欣禾工程管理咨询有限公司

Gold smelting wastewater MVR evaporator

PendingCN111547798ARealize automatic deliveryImprove work efficiencyWaste water treatment from metallurgical processWater/sewage treatment by heatingProcess engineeringCirculating pump

The invention discloses a gold smelting wastewater MVR evaporator, relates to the field of gold smelting wastewater treatment equipment. In the prior art, most of existing MVR evaporators are conveyedafter crystals are manually removed, and no special conveying equipment exists. The invention just aims to solve the above problem in the prior art. A discharge port of a stock solution tank is connected with a feed port of a first delivery pump through a liquid delivery pipe; a discharge port of the first conveying pump is connected with a feed port of a preheater through a liquid conveying pipe; an evaporator is arranged on one side of the preheater; a steam conveying pipe is arranged on the outer surface of one side of the evaporator; a heat exchanger is arranged on one side of the evaporator; a distillation pump is arranged on one side of the heat exchanger; a steam compressor is arranged on one side of the heat exchanger; a first crystallization separator is arranged on one side of the steam compressor; and a circulating pump is arranged on one side of the first crystallization separator.

Owner:江苏慧发企业管理有限公司

A kind of urban garbage disposal equipment and its application method

The present invention proposes a kind of urban garbage treatment equipment, which comprises a transmission threaded rod, a threaded sleeve, a threaded hole on the threaded sleeve, and a cylindrical shell, the upper surface of which is provided with a movable hole, and the transmission threaded rod passes through the threaded hole, The movable hole is inserted into the cylindrical shell, and the transmission threaded rod is rotationally connected with the cylindrical shell, and also includes a connecting rod, which is fixedly connected to the transmission threaded rod, and also includes a garbage disposal bin, the bottom of which passes through the lower surface of the cylindrical shell and puts the garbage In the processing chamber, a blade set is arranged on one side of the connecting rod, and it also includes a beveled cylinder and two extruding rods. The beveled cylinder is fixedly sleeved on the connecting rod. The slope of the cylinder is connected flexibly, and the bottom of each extrusion rod is fixedly connected with a pressing plate. When the equipment disposes of garbage, the rolling method is faster, the action area is small, and the energy consumption is less, which can save energy, and the environmental protection factor is high, which can greatly improve the efficiency of rolling.

Owner:湖南万丰环保科技发展有限公司

Bucket pump liquid supply distributed direct-cooling condensing unit for industrial VOCs tail gas recovery

PendingCN114857791AAvoid being influenced by the external environmentReduce energy consumptionCompressorMechanical apparatusEngineeringMechanics

The invention discloses a barrel pump liquid supply distributed direct-cooling condensing unit for industrial VOCs tail gas recovery, relates to the technical field of crushing of friction materials, and aims at solving the problems that an existing condensing unit is prone to being affected by the external environment, the overall condensing effect needs to be improved, and meanwhile the manufacturing cost and the maintenance cost need to be reduced. Two fixed supporting frames are fixedly connected to the upper surface of the fixed bottom frame, a low-pressure circulating barrel is fixedly mounted in mounting grooves of the fixed supporting frames, an inner partition plate is arranged in an interlayer of the barrel wall of the low-pressure circulating barrel, a vacuum layer is arranged on one side of the inner partition plate, and the space of the other side of the inner partition plate is filled with heat preservation cotton. And a liquid conveying pipe is fixedly connected to the side surface of the bottom of the low-pressure circulating barrel, a second conveying pump is fixedly installed in a pipeline of the liquid conveying pipe, and a material returning pipe and an air suction pipe are fixedly connected to the side surface of the top of the low-pressure circulating barrel.

Owner:安徽恒星世纪空调制冷设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com