A double-layer composite wood floor and its preparation method

A double-layer composite and wooden floor technology, applied in the direction of building materials, etc., to achieve the effect of reducing wood felling, convenient installation and laying, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

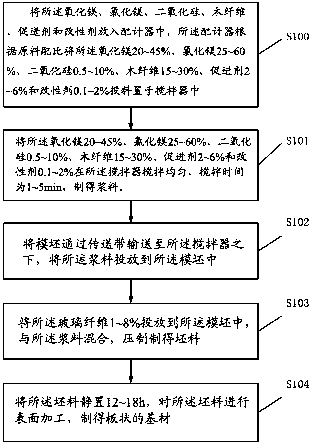

Embodiment 1

[0180] The magnesium oxide, magnesium chloride, silicon dioxide, wood fiber, accelerator and modifier are put into the blender, and the blender mixes 20% of the magnesium oxide, 55% of magnesium chloride, two Silicon oxide 0.5%, wood fiber 15%, accelerator 2.5% and modifying agent 1% feed intake are placed in agitator; Described magnesium oxide 20%, magnesium chloride 55%, silicon dioxide 0.5%, wood fiber 15%, Accelerator 2.5% and modifier 2% are stirred evenly in the agitator, and the stirring time is 1-5min to prepare a slurry; the mold base is conveyed under the agitator through a conveyor belt, and the slurry is put into into the mold base; put 5% of the glass fiber into the mold base, mix with the slurry, and press to obtain a blank; leave the blank for 12 to 18 hours, and perform surface treatment on the blank. Processing to obtain a plate-shaped base material; the AB cold pressure glue added with 0.5% catalyst unsaturated resin is applied to the base material and bonded...

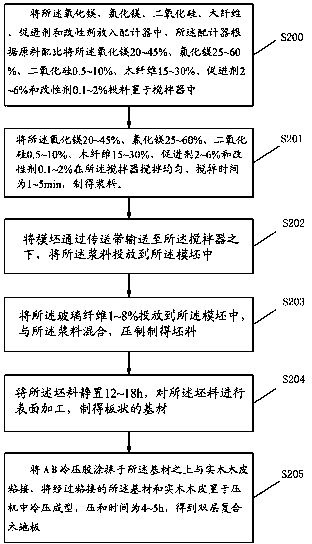

Embodiment 2

[0182]The magnesium oxide, magnesium chloride, silicon dioxide, wood fiber, accelerator and modifier are put into the blender, and the blender mixes 30% of the magnesium oxide, 32% of magnesium chloride, two Silicon oxide 5%, wood fiber 23%, accelerator 3% and modifier 1% feed intake are placed in agitator; Described magnesium oxide 30%, magnesium chloride 32%, silicon dioxide 5%, wood fiber 23%, Accelerator 4% and modifier 1% are stirred evenly in the agitator, and the stirring time is 1-5min to prepare a slurry; the mold base is conveyed under the agitator through a conveyor belt, and the slurry is put into into the mold base; put 6% of the glass fiber into the mold base, mix with the slurry, and press to obtain a blank; leave the blank for 12 to 18 hours, and surface the blank Processing to obtain a plate-shaped base material; AB cold-press glue added with 1% catalyst unsaturated resin is applied to the base material and bonded to the solid wood veneer, and the bonded base ...

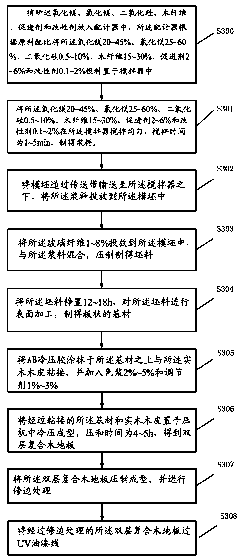

Embodiment 3

[0184] Put the magnesium oxide, magnesium chloride, silicon dioxide, wood fiber, accelerator and modifying agent into the blender, and the blender mixes 40% of the magnesium oxide, 25% of magnesium chloride, two Silicon oxide 4%, wood fiber 21%, accelerator 3.5% and modifying agent 1.5% feed intake are placed in agitator; Described magnesium oxide 40%, magnesium chloride 25%, silicon dioxide 4%, wood fiber 21%, Accelerator 4% and modifier 1.5% are stirred evenly in the agitator, and the stirring time is 1~5min to prepare a slurry; the mold base is conveyed under the agitator by a conveyor belt, and the slurry is put into into the mold base; put 2% of the glass fiber into the mold base, mix with the slurry, and press to obtain a blank; leave the blank for 12 to 18 hours, and perform surface treatment on the blank. Processing to obtain a plate-shaped substrate; AB cold-press glue added with 1.5% catalyst unsaturated resin is applied to the substrate and bonded with the solid woo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com