Environment-friendly garbage rolling compaction device

An environmentally friendly and garbage-friendly technology, which is applied in the direction of garbage cans, garbage collection, garbage storage, etc., can solve the problems of increasing the cost of garbage rolling, occupying a large area, and reducing efficiency, so as to improve the quality of garbage rolling and high environmental protection factor , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

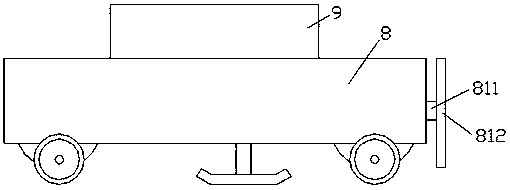

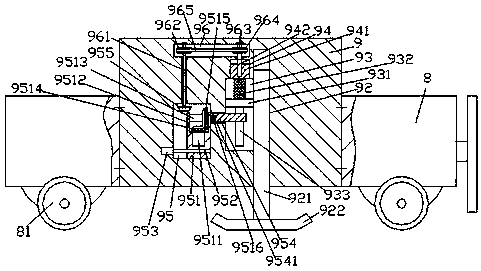

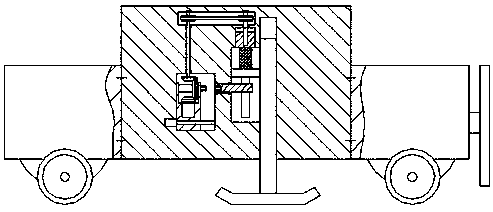

[0016] Such as Figure 1-Figure 5 As shown, an environment-friendly garbage rolling device of the present invention includes a walking body 8 and a garbage rolling body 9 fixedly installed in the walking body 8, and the right end surface of the walking body 8 is fixedly installed with a cross arm 811 Push plate 812, said push plate 812 is provided with a port 813 that extends up and down and communicates with left and right, said push plate 812 is used to flatten the rubbish, preventing the rubbish from being too high and affecting the walking of the walking body 8, and said rubbish rolling The body 9 is provided with a first sliding groove 92 extending downwards and penetrating through the bottom end surface of the garbage compacting body 9. The left inner wall of the first sliding groove 92 communicates with a first transition groove 93. The inner top wall of the first transition groove 93 communicates with a guide groove 94, and the inner wall of the garbage rolling body 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com