Internally arranged steel plate support for light steel assembled wallboard

A steel plate and wallboard technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of brittle failure, deterioration of steel plate support ductility and energy dissipation capacity, and wallboard self-weight, etc., to prevent overall and local instability, improve Ductility and energy dissipation capacity, the effect of improving ductility and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

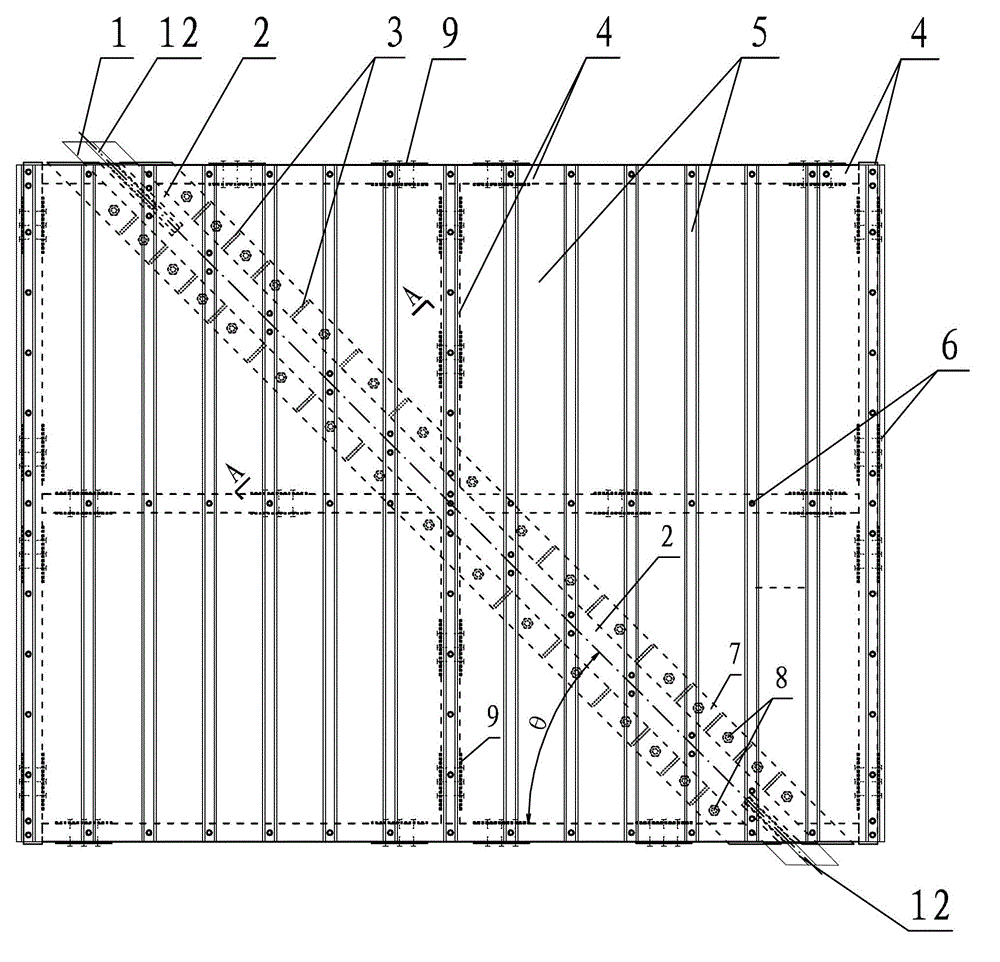

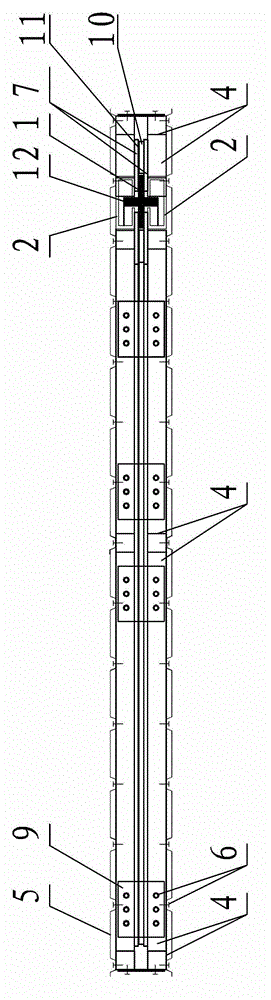

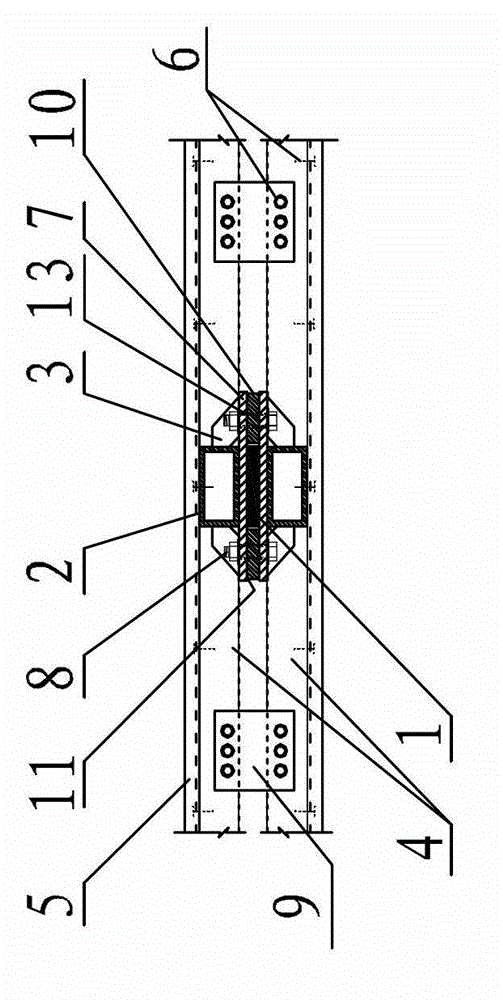

[0014] Specific implementation one: as Figures 1 to 11 As shown, the built-in steel plate support of the light steel assembled wall panel in this embodiment includes a steel plate support body 1 and a light steel assembled wall panel, and two first stiffeners 12 are welded on both ends of the steel plate support body 1 along the length direction. , the two first stiffeners 12 located at the same end of the steel plate support body 1 are symmetrically and vertically arranged with respect to the steel plate support body 1. The light steel assembled wall panel is composed of a wall panel frame and two pressure-shaped color steel plates 5. The wall panel frame includes Two first rectangular steel pipes 2, two steel plates 7, two perforated steel pads 10, two perforated adjustment pads 11, multiple second rectangular steel tubes 4, multiple second stiffeners 3, multiple high-strength The bolts 8 and a plurality of connecting steel plates 9, the steel plate support body 1, the perf...

specific Embodiment approach 2

[0019] Embodiment 2: In this embodiment, the upper end of the first stiffening rib 12 located at the lower end of the steel plate support body 1 is in close contact with the upper ends of the first rectangular groove 7-1 and the second rectangular groove 2-1 at the lower part; A gap is left between the lower end of the stiffening rib 12 and the lower end of the upper first rectangular groove 7-1 and the lower end of the second rectangular groove 2-1 along the axial direction of the steel plate support 1 . In this way, the light steel assembled wall panel can transmit the dead weight of the wall panel to the steel frame through the close contact with the first stiffener 12 at the lower end of the steel plate support body 1, which is conducive to supporting the force; the lower end of the upper stiffener 12 of the steel plate support 1 There is a gap along the axial direction of the steel plate support 1, so that after the steel plate support 1 is compressed, it can be freely sho...

specific Embodiment approach 3

[0020] Specific implementation three: as Image 6 As shown, in this embodiment, each square-shaped lattice frame is welded by a plurality of second rectangular steel pipes 4 . With this design, two wall panel skeletons with good integrity can be formed on both sides of the front and back of the wall panel respectively. Other compositions and connection methods are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com