Steel truss suspension hybrid system and construction method

A hybrid system and construction method technology, applied in the direction of architecture and building structure, can solve the problems of high construction technology requirements, large design section, and constantly changing structural stress state, and achieves a structure that is conducive to earthquake resistance and reduced size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

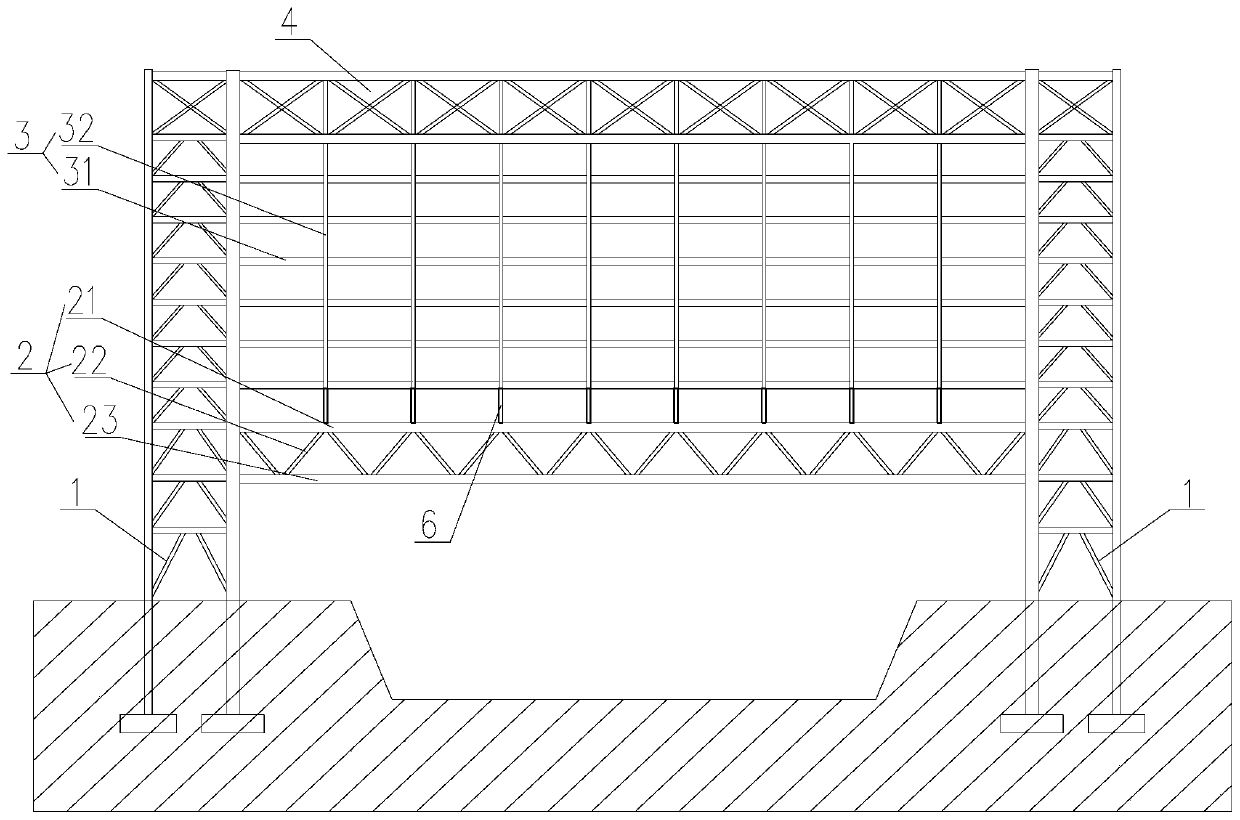

[0026] Such as figure 2 As shown, a steel truss suspension hybrid system includes two vertically arranged vertical frames 1, an upper truss 4 arranged between the two vertical frames 1 and arranged in parallel up and down, several layers of suspension units 3, and a lower truss 2. Each layer of suspension unit 3 includes a frame beam 31 arranged horizontally, a suspension column 32 vertically arranged between the frame beams 31 of two adjacent layers, and the frame beam 31 in the suspension unit 3 of the lowest layer passes through the supplementary suspension body 6 and the lower part Truss 2 connections. Wherein the vertical frame 1 is a steel frame.

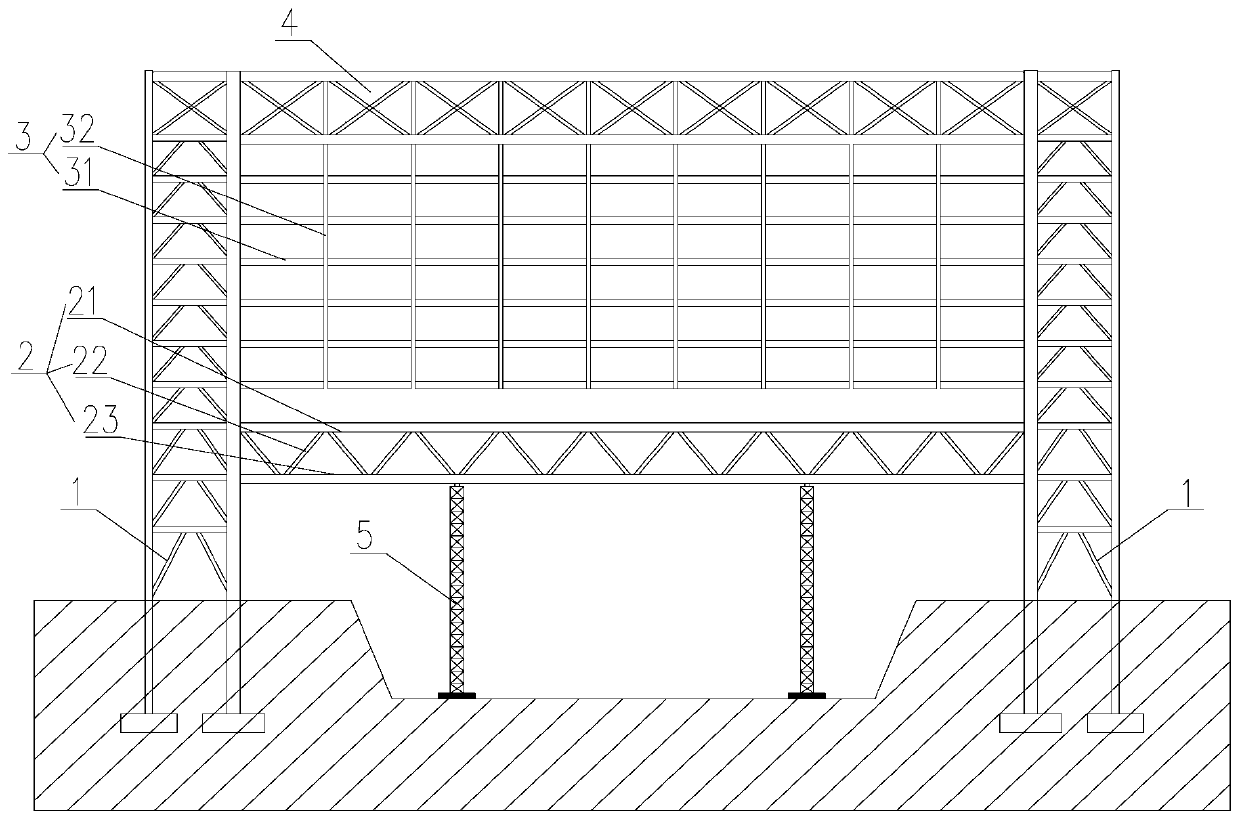

[0027] Such as figure 1 As shown, in order to realize the formation of the hybrid system, the system also includes a borrower, and the borrower includes a first support unit (the position of the first support unit is the same as that of the supplementary suspension body, in order not to conflict with the supplementary suspe...

Embodiment 2

[0029] Build the construction method of a steel truss suspension hybrid system described in Example 1, which is a step of forward installation, as follows:

[0030] S1, install the vertical frame 1 on both sides;

[0031] S2. Several upward second support units 5 are vertically arranged between the two vertical frames 1, and the lower truss 2 is mounted on the second support unit 5, and then the two ends of the lower truss 2 are respectively connected to the corresponding vertical Frame 1 is fixedly connected, and profiled plates are installed on the upper and lower end surfaces of the lower truss 2, and concrete is poured, skipping to step S3;

[0032] S3. Set the first support unit on the lower truss 2, the frame beam 31 of the suspension unit 3 of the first layer is erected on the first support unit, and the two ends are respectively connected with the corresponding vertical frame 1, and then the corresponding frame beam Suspension columns corresponding to the suspension u...

Embodiment 3

[0039] Build the construction method of a kind of steel truss suspension hybrid system described in embodiment 1, this embodiment is the steps during reverse installation, specifically as follows:

[0040] S1, install the vertical frame 1 on both sides;

[0041] S6. Fix the two ends of the lower truss 2 and the lower truss 2 between the vertical frames 1 on both sides respectively, and install profiled plates on the upper and lower surfaces of the lower truss 2 and the upper truss 4 respectively, pour concrete, and the concrete solidifies Then enter step S7;

[0042] S7, the N-layer suspension unit 3 is sequentially arranged between the lower truss 2 and the upper truss 4 from top to bottom, and enters step S8; specifically, hang the suspension column 32 in the N-th layer of suspension unit 3 below the upper truss 4, Then the frame beam 31 in the suspension unit 3 of the Nth layer is connected at the lower end of the suspension column 32, the frame beam 31 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com