A method for externally prestressed steel plate flexural strengthening beam

A technology of external prestressing and reinforcing beams, applied in construction, building maintenance, building types, etc., can solve the problem that the passive reinforcement method has no theoretical formula to check the specification for stiffness and deformation, the material strength cannot be fully exerted, and the passive reinforcement method is lag in force, etc. problems, to achieve the effect of being beneficial to the structure's earthquake resistance, low cost of engineering materials, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

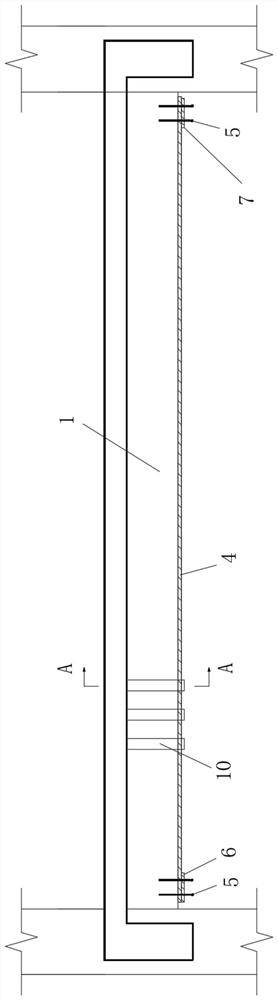

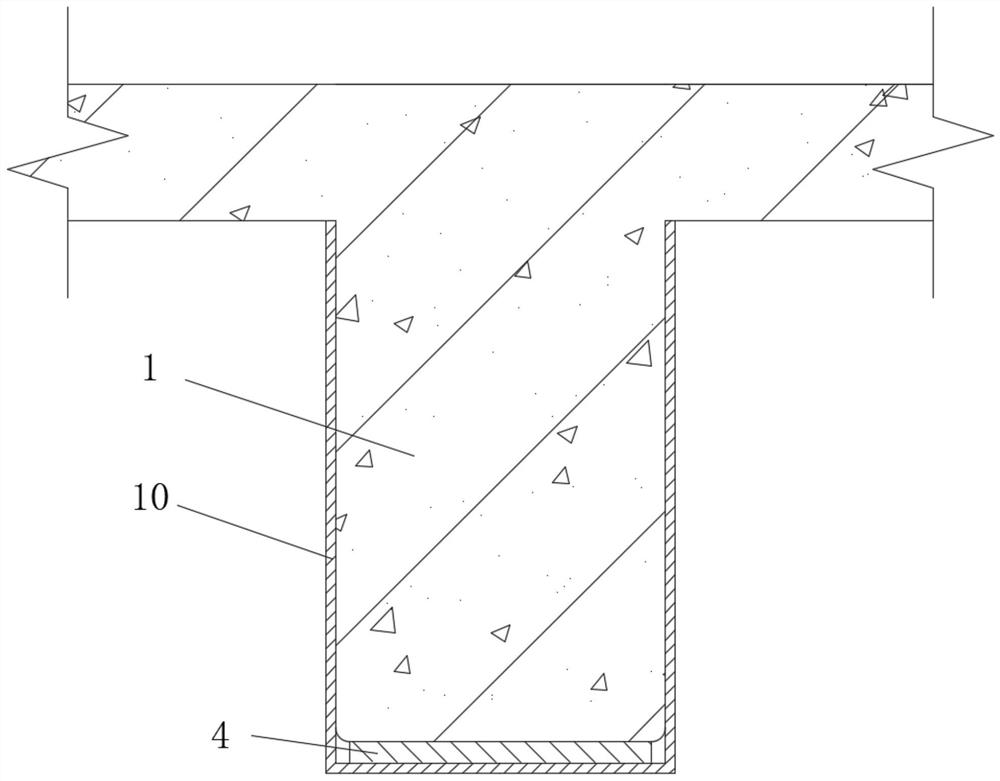

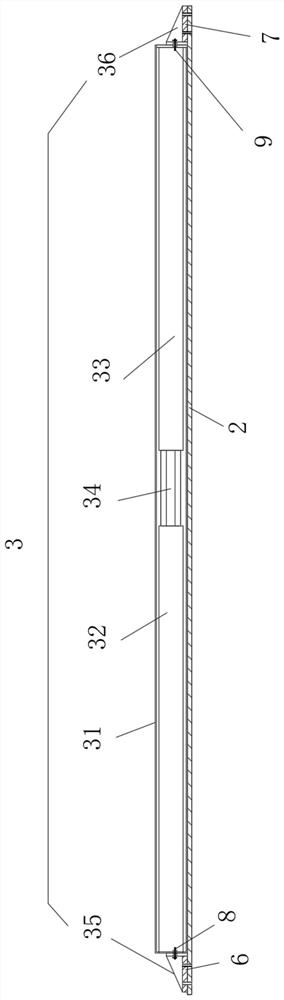

[0024] Such as Figure 1-3 As shown, a method for externally prestressed steel plate flexurally strengthened beams comprises the following steps:

[0025] (S1), carry out status appraisal of the beam 1 to be strengthened, and then select the steel plate 2 to be treated according to the design requirements;

[0026] (S2), using the tensioning device 3 to connect with the steel plate to be processed 2 to form a tension self-balance system and stretching the steel plate to be processed 2, so that the elongation of the steel plate to be processed 2 can meet the design requirements, and obtain a predetermined Stress steel plate 4;

[0027] (S3), grinding and cleaning the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com