Assembled wall panels with built-in self-resetting steel plate supports

A self-reset, steel plate technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of self-heavy wall panels, deteriorated steel plate support ductility and energy consumption capacity, difficult to check and replace steel plate supports, etc., to improve ductility and consumption. energy capacity, improve ductility and energy dissipation capacity, reduce the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

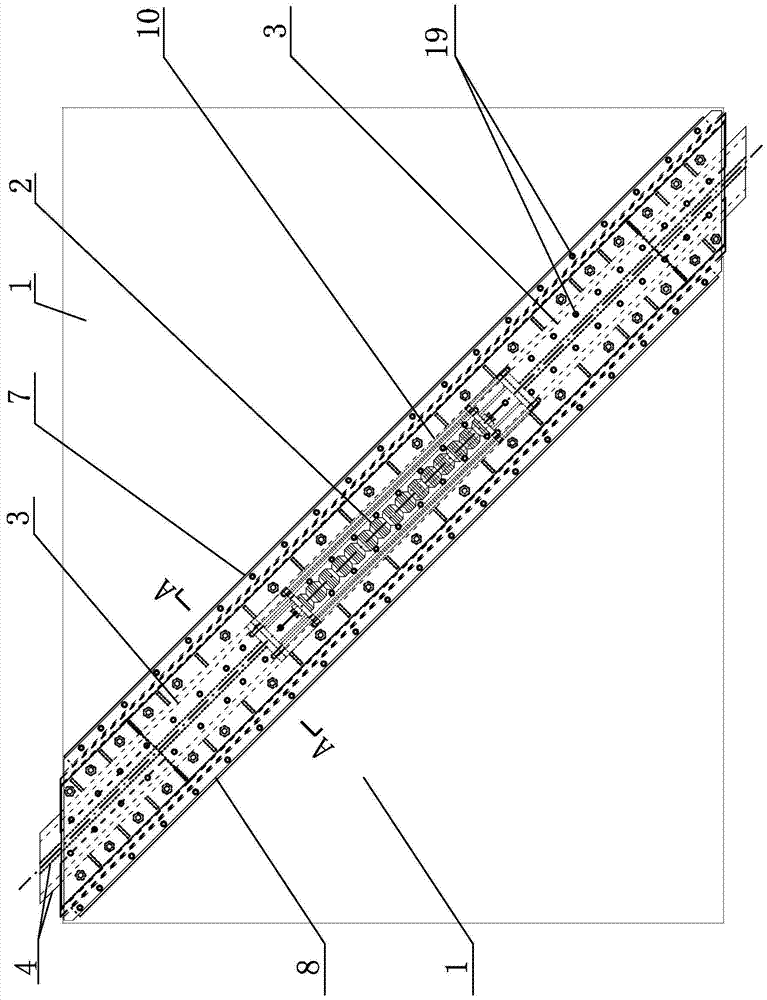

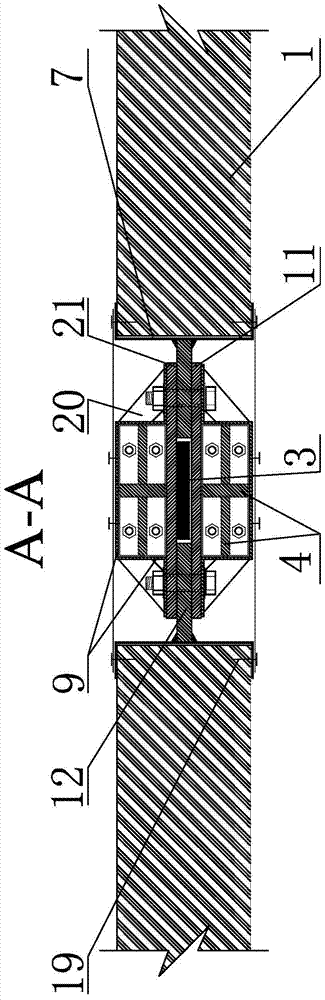

[0015] Specific implementation mode one: combine Figure 1-Figure 19 Describe this embodiment, the assembled wallboard of this embodiment has a built-in self-resetting steel plate support, which includes a wall body 1 and a self-resetting support mechanism 10, and the self-resetting support mechanism 10 includes a supporting steel plate 3, two compressed spring assemblies 2, four Push-pull block 6, two channel steels 7, two cover plates 8, two hat-shaped steels 9, two fixed steel plates 11, two fixed tension plates 12, four push-pull rods 4 and four end plates 5; Two compressed spring assemblies 2 are arranged side by side, and a push-pull block 6 is respectively provided at both ends of each compressed spring assembly 2, and each compressed spring assembly 2 is fixedly connected with two push-pull blocks 6, and each end plate 5 One end face is connected to one end of the push-pull block 6, the other end face of the end plate 5 is fixedly connected to one end of a push-pull ro...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the assembled wall panel of this embodiment is supported by a built-in self-resetting steel plate, and the push-pull block 6 includes a bottom plate 13, a top plate 14 and four connecting and fixing plates 15; the bottom plate 13 and the top plate 14 are arranged in parallel, and the bottom plate 13 and the top plate 14 are connected by four connecting and fixing plates 15, and the four connecting and fixing plates 15 are welded and installed on the bottom plate 13 and the top plate 14, and other structures are the same as those in the first embodiment.

specific Embodiment approach 3

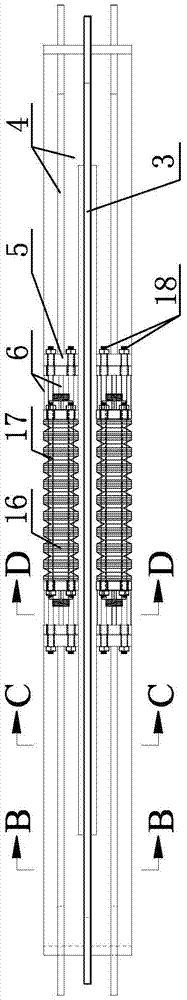

[0020] Specific implementation mode three: combination Figure 1-Figure 8 Describe this embodiment, the assembled wallboard of this embodiment has a built-in self-resetting steel plate support, and the pressure spring assembly 2 includes a group of disc springs 16, a pre-tension rod 17 and eight external screw rods 18; the pre-tension rod 17 The two ends are respectively processed with external threads, and the two ends of the external screw rod 18 are respectively processed with external threads. The pre-tension rod 17 is arranged on one side of the supporting steel plate 3, and a group of disc springs 16 are sleeved on the pre-tension rod 17. The two ends of the tight rod 17 are respectively arranged on the two bottom plates 13, two nuts are respectively installed at the two ends of the pre-tension rod 17, and four outer screw rods 18 are fixedly installed on each push-pull block 6, which are located on the same side of the supporting steel plate 3 Four outer screw rods 18 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com