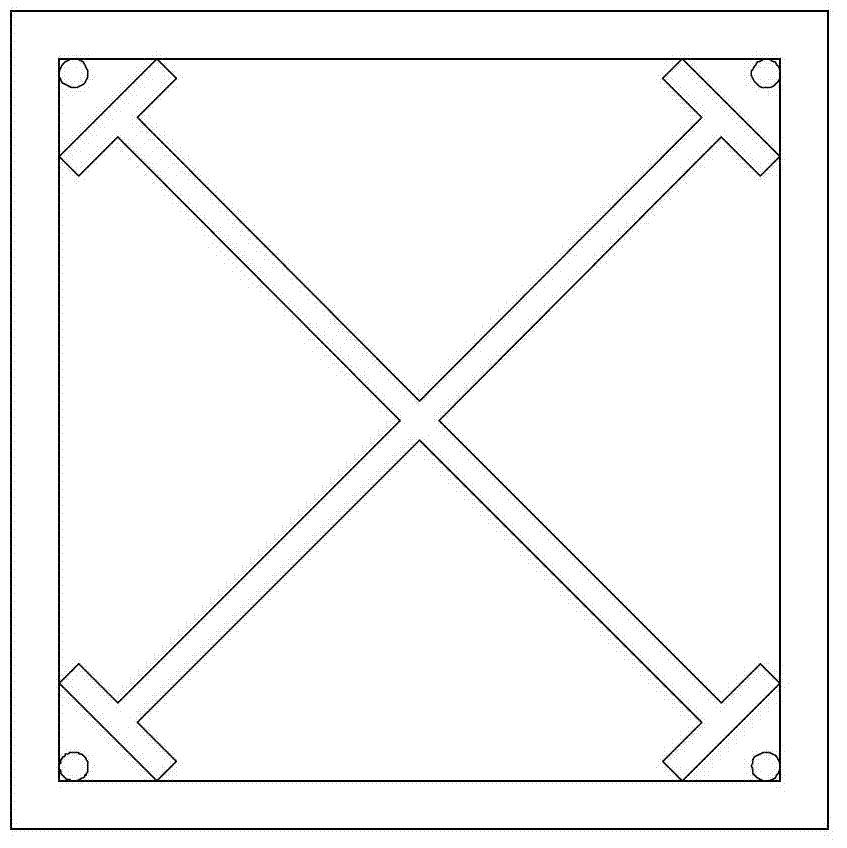

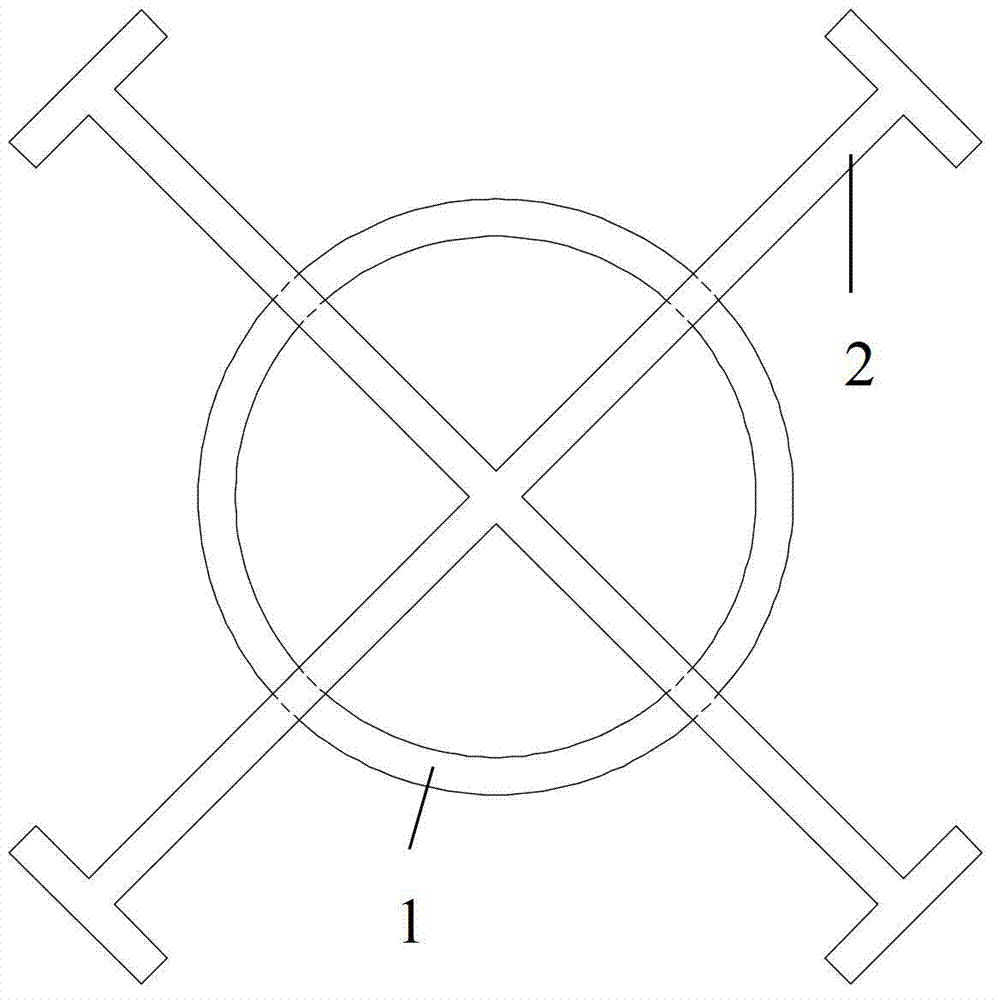

Node for combination beam and 45-degree arranged cross steel reinforced concrete column

A technology of concrete column and cross-shaped steel, applied in the direction of building, building structure, etc., can solve the problems of shear brittle failure, unfavorable stress state of structure, structural collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

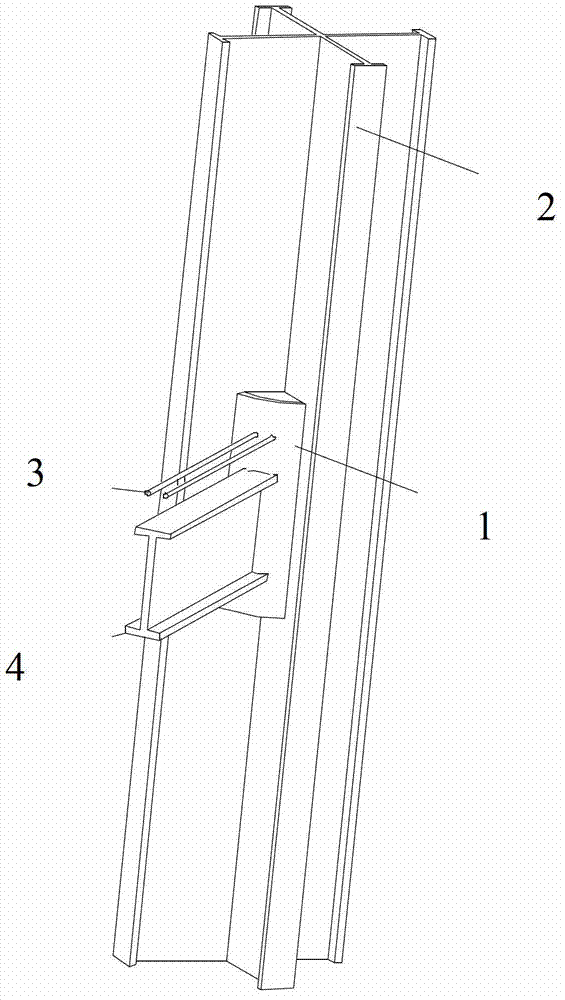

[0036] The shaped steel column 1 is made by a professional steel structure company, and the shaped steel column 1 is welded by I-shaped steel 5 and two T-shaped steels 7 . When making the I-beam 5, cut out a cavity 6 within the range of node height, the hole height of the cavity 6 is equal to the height of the round steel pipe, and the hole width is the outer diameter of the round steel pipe. The round steel pipe 1 is placed on the I-beam 5 In the cut cavity 6, the webs of the round steel pipe 1 and the I-beam 5 are welded. The two T-shaped steels 7 are welded to the I-shaped steel 5, and the round steel pipe 1 is welded to the webs of the two T-shaped steels 7 at the same time. After the above work is completed, you can see as follows figure 2 shown. The steel bar 3 in the composite beam is plug-welded on the round steel pipe 1, and the steel beam 4 in the composite beam is welded on the round steel pipe 1. The stirrups of the nodes can be welded to the webs of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com