Portable numerical control hole boring equipment for processing sealing surface of valve seat of gas turbine and application of portable numerical control hole boring equipment

A gas turbine, sealing surface technology, applied in metal processing equipment, drilling/drilling equipment, boring/drilling, etc., to achieve the effects of simple assembly, continuous feeding, and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

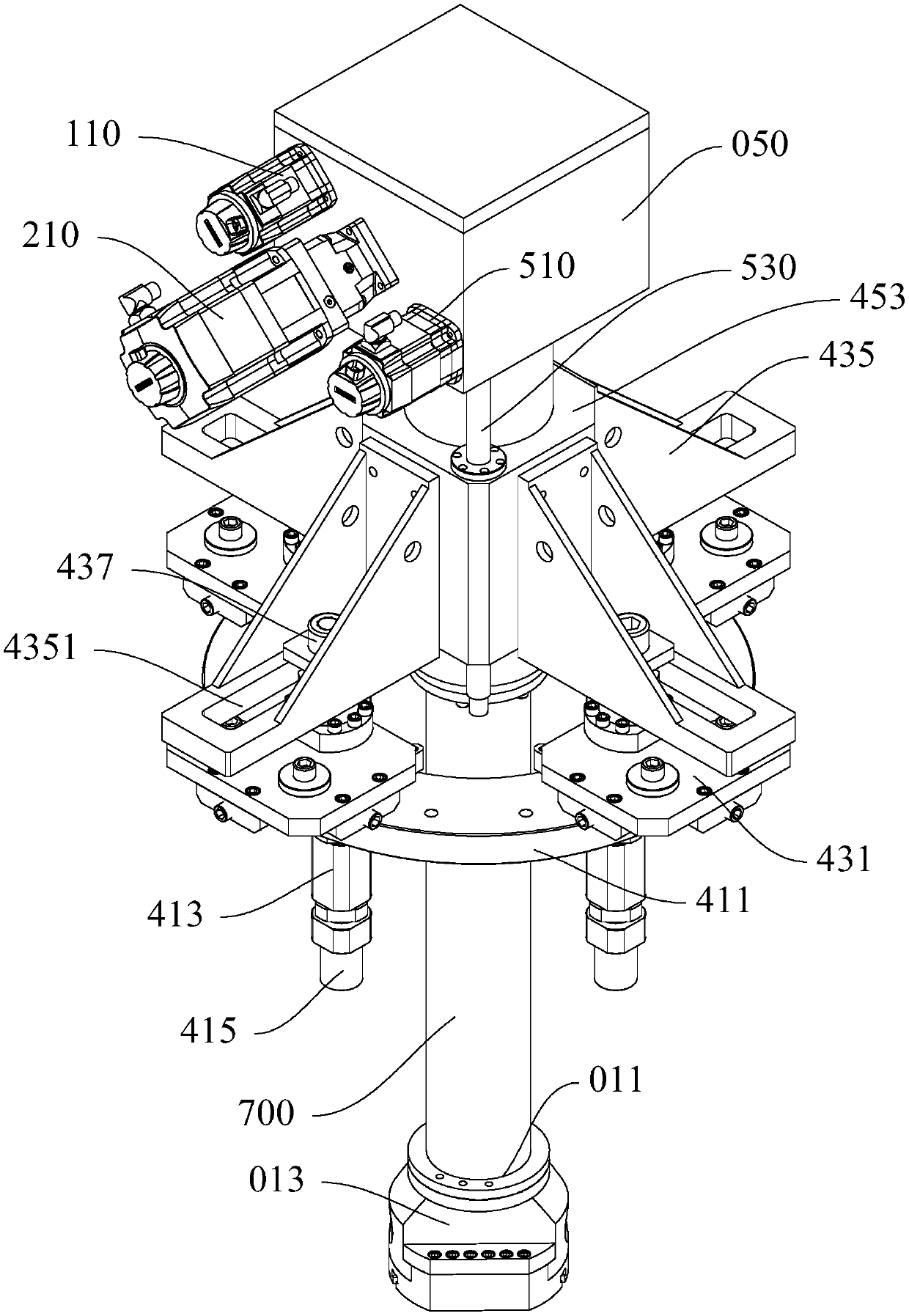

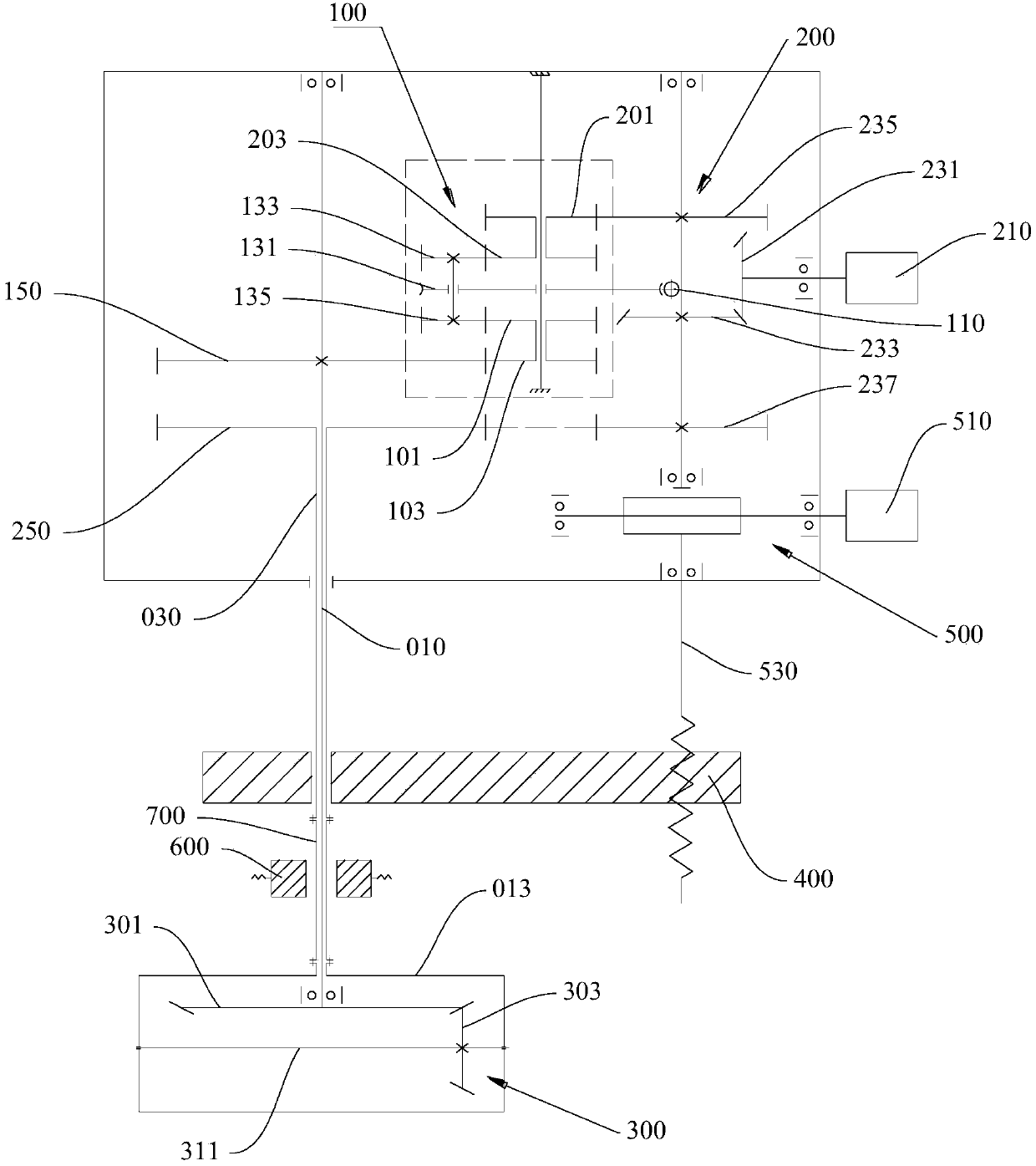

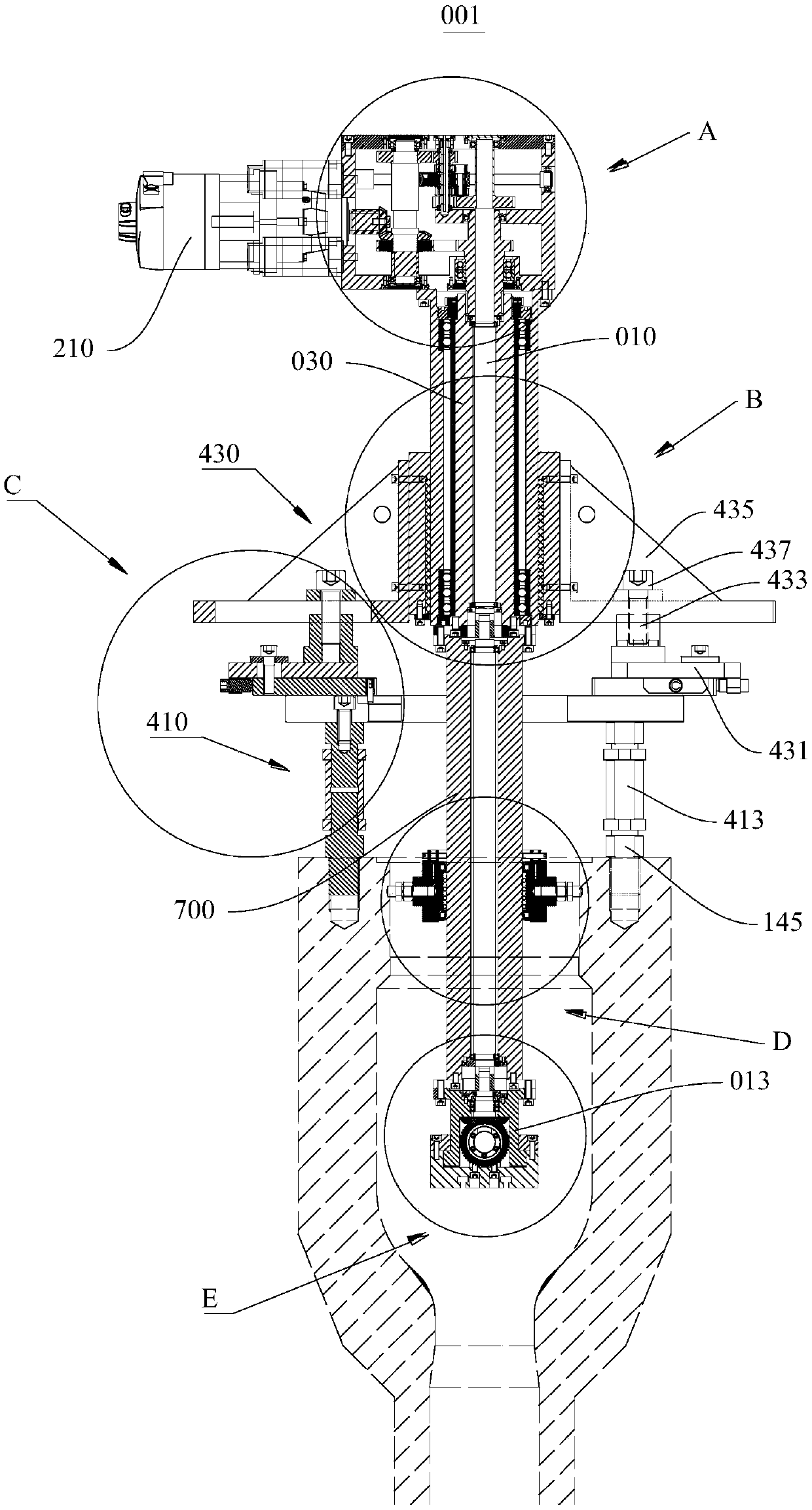

[0066] This embodiment provides a portable numerical control boring equipment 001 for processing the sealing surface of gas turbine valve seat, please refer to figure 1 with figure 2 , this gas turbine valve seat sealing surface processing portable CNC boring equipment 001 includes a radial control rod 010, a spindle boring bar 030, a radial control rod drive assembly 100, a spindle boring bar drive assembly 200, and a differential assembly 300;

[0067] The spindle boring bar 030 is coaxially sleeved on the outside of the radial control rod 010; the radial control rod drive assembly 100 drives the radial control rod 010 to rotate, and the spindle boring bar drive assembly 200 drives the spindle boring bar 030 to rotate;

[0068] The radial control rod 010 and the spindle boring bar 030 have a common working end 011, and the differential assembly 300 is arranged on the working end 011;

[0069] see image 3 , Figure 8 with Figure 10 , the differential assembly 300 inclu...

Embodiment 2

[0103] This embodiment provides an application of a portable numerical control boring device 001 for processing the sealing surface of a gas turbine valve seat. The application of the portable numerical control boring device 001 for processing the sealing surface of a gas turbine valve seat uses the sealing surface of a gas turbine valve seat provided in Embodiment 1. Processing portable CNC boring equipment 001, including steps:

[0104] A. Install the mounting bracket 400 in the portable CNC boring equipment 001 for processing the sealing surface of the gas turbine valve seat on the gas turbine valve seat that needs to process the sealing surface;

[0105] B. Assemble and debug the radial control rod drive assembly 100 and the spindle boring bar drive assembly 200 in the portable CNC boring equipment 001 for processing the sealing surface of the valve seat of the gas turbine; the radial control rod drive assembly 100 and the spindle boring bar drive assembly 200 pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com