Novel fireproof and waterproof composite heat preservation wall structure

A composite thermal insulation and wall structure technology, applied in thermal insulation, fire protection, building thermal insulation materials, etc., can solve the problems of limited use and low fire protection level, and achieve the effect of improving fire protection level, improving waterproof performance, and improving installation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

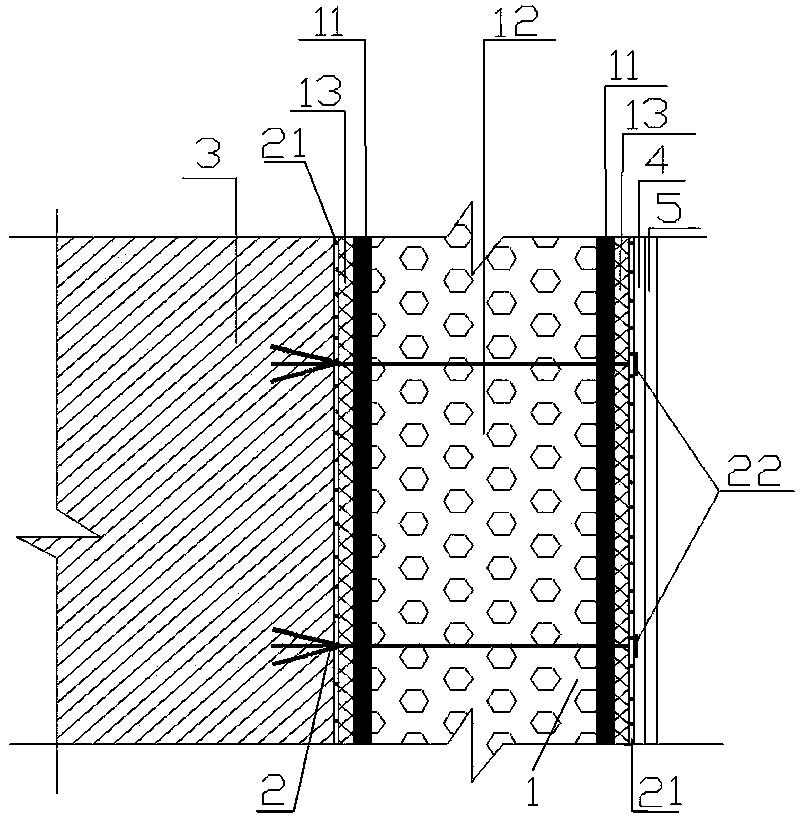

[0009] see figure 1 As shown, the present invention provides a novel fireproof and waterproof composite thermal insulation wall structure, which is composed of a composite thermal insulation board 1 and a fixed grid 2 installed on the outside of the structural wall, and is characterized in that: both sides of the composite thermal insulation board are aluminum foil plates Layer 11, the middle is a polystyrene board insulation layer 12, and the aluminum foil board layer and the polystyrene board insulation layer are connected by an adhesive layer 13; the fixed grid includes a wire mesh 21 and an expansion rivet 22, and the wire mesh 21 is located on both sides of the composite insulation board, the bottom of the expansion rivet is anchored on the structural wall 3, the middle part passes through the composite insulation board 1 and the wire mesh 21, the top is connected with the outer wire mesh 21, and the outer wire mesh An adhesive mortar layer 4 is provided, and a facing lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com