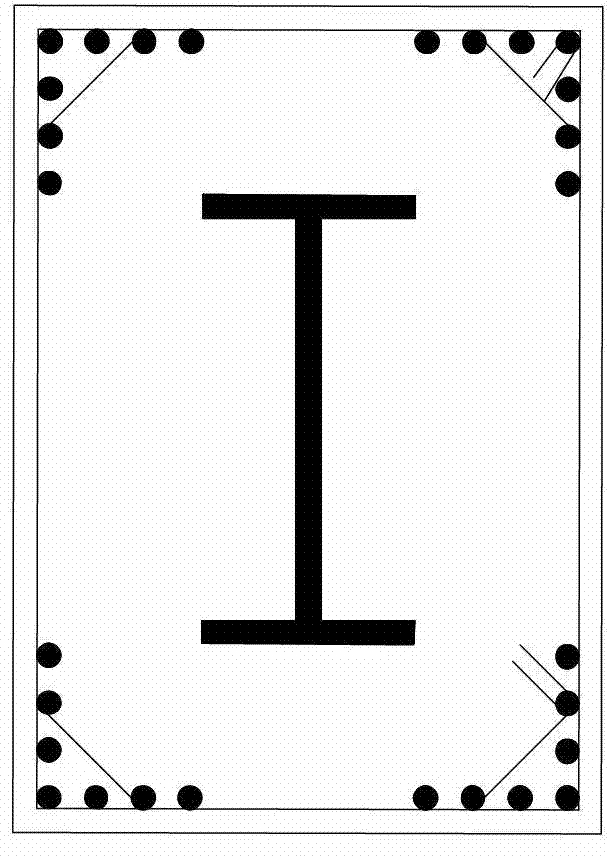

H-shaped steel concrete column with high-strength spiral hoop and restraining high-strength wide flange

A technology of concrete columns and spiral hoops, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as unsatisfactory, inconvenient construction, and the inability of section steel to fully exert its bending resistance, and achieve the effect of improving various indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

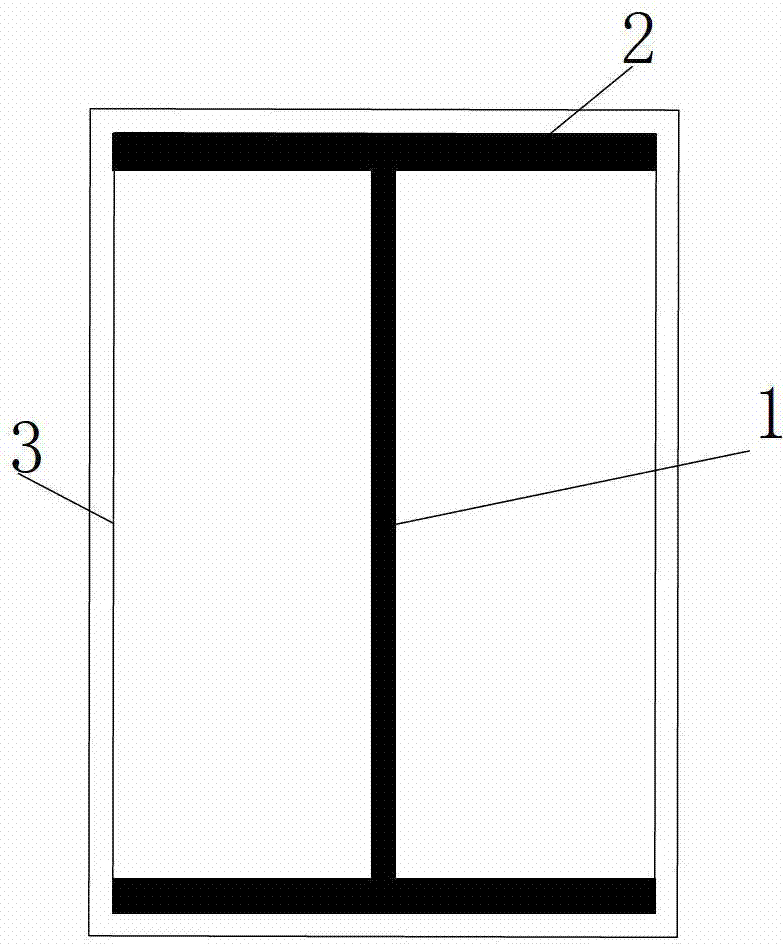

[0039] The shaped steel column 1 is made by a professional steel structure company. The width of the shaped steel flange 2 is equal to the width of the column minus 70mm. When processing the shaped steel flange and web, round holes are set on it. The rectangular spiral hoop is processed by the CNC hoop bending machine with a machining accuracy of ±1mm. The manufactured rectangular spiral hoop 3 is placed on the section steel, and the inner surface of the spiral hoop constraining the section steel flange 2 should be attached to the outer surface of the section steel flange. A section of shaped steel column corresponds to several circles of spiral hoops. The initial end of the spiral hoop must surround the shaped steel for one circle, and the end of the spiral hoop must surround the shaped steel for one circle. Less than 10d, the strength of the electrode is not less than 500 MPa, and the weld must be full.

PUM

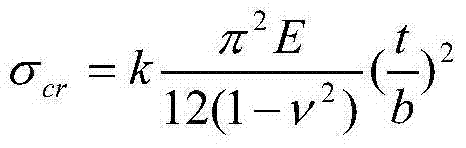

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com