Structure beam in calcium carbide production equipment

A production device and a technology for structural beams, applied in the direction of building structures, carbides, calcium carbides, etc., can solve the problems that the rectangular distribution system of reinforced concrete beams cannot be realized, and achieve compact plane layout, which is conducive to structural earthquake resistance and reasonable building heights Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

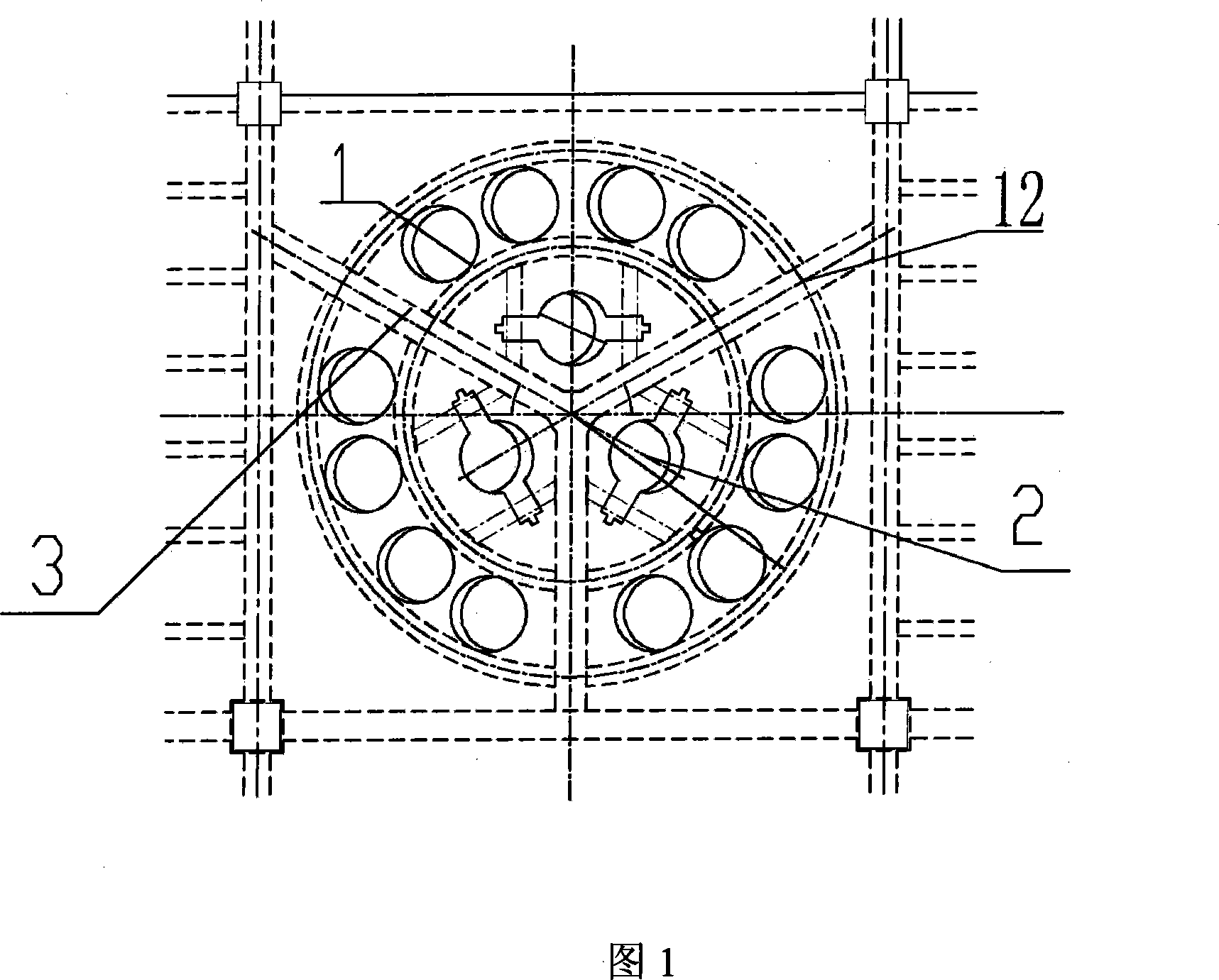

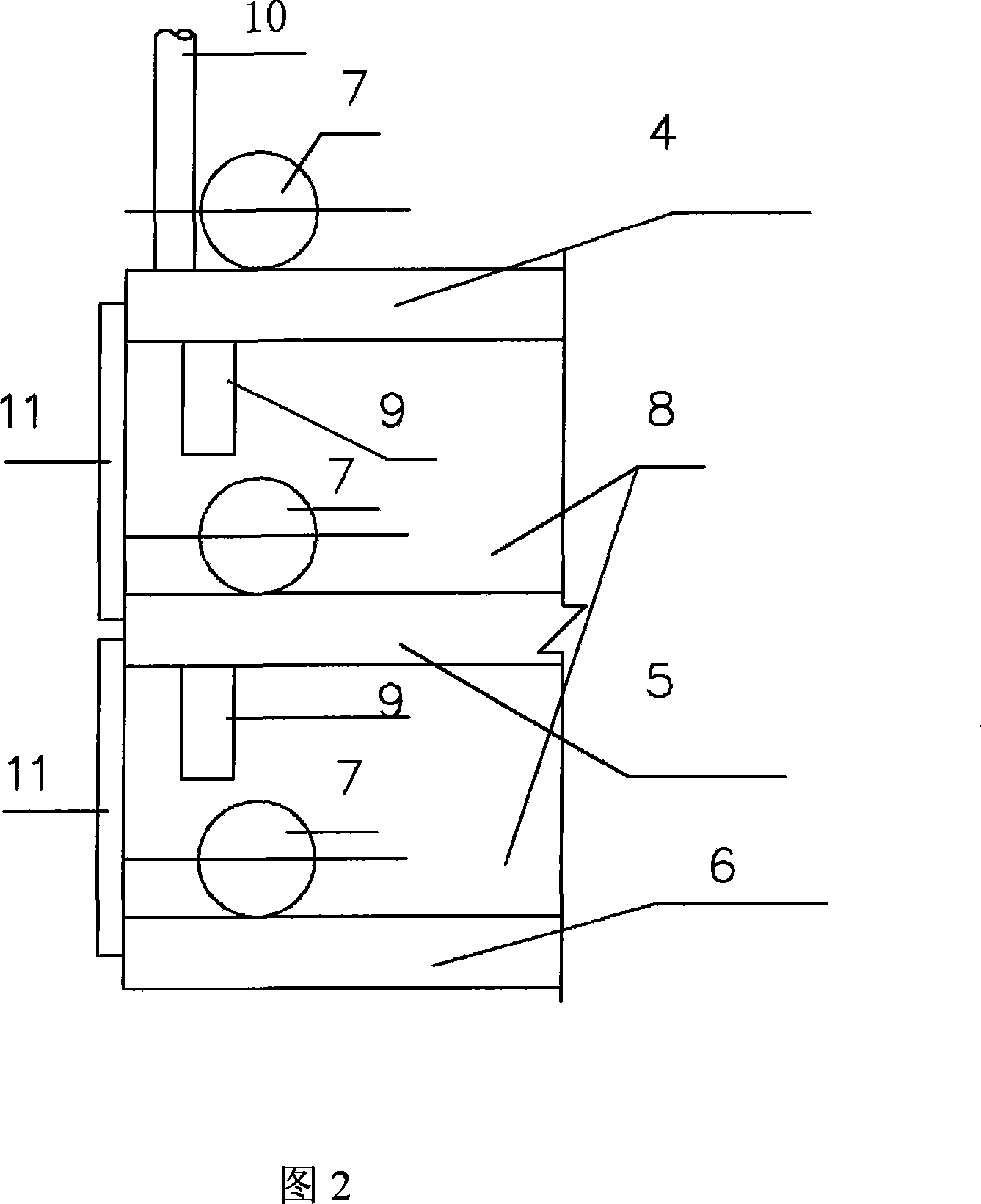

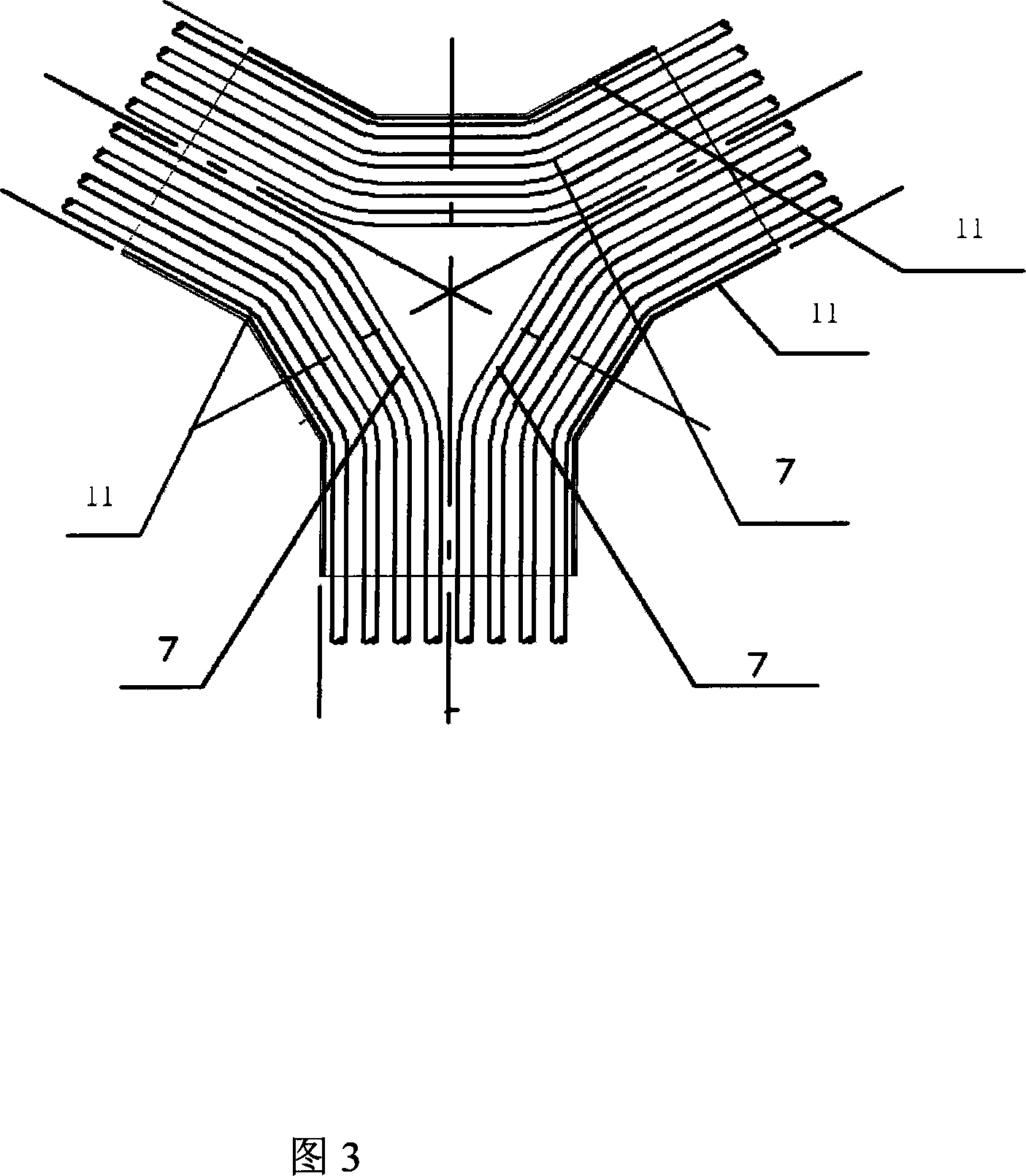

[0013] A structural beam in a calcium carbide production device as shown in Figures 1-3, it includes a concrete trident beam 12 composed of three limbs 3 arranged in a herringbone shape, the three limbs converge at a point in the middle and each limb The included angle between each other is 120 degrees, and the upper, middle and lower three-layer steel plates 4, 5, and 6 are arranged on the lower part of each concrete beam limb that converges at the middle point, and the preferred distance between each layer of steel plates is The spacing is 90-110mm, which is conducive to the dense combination of grouting material, steel bars and steel plates without causing the layer spacing of steel bars to be too large, so that the steel bars can bear reasonable stress. A plurality of steel bars 7 are welded on each layer of steel plates, and the steel bars are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com