Inner truss type steel tube concrete L-shaped column and construction method thereof

A steel tube concrete and inner truss type technology, applied in the field of special-shaped columns, to achieve the effects of fast and convenient construction, convenient pouring of concrete, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

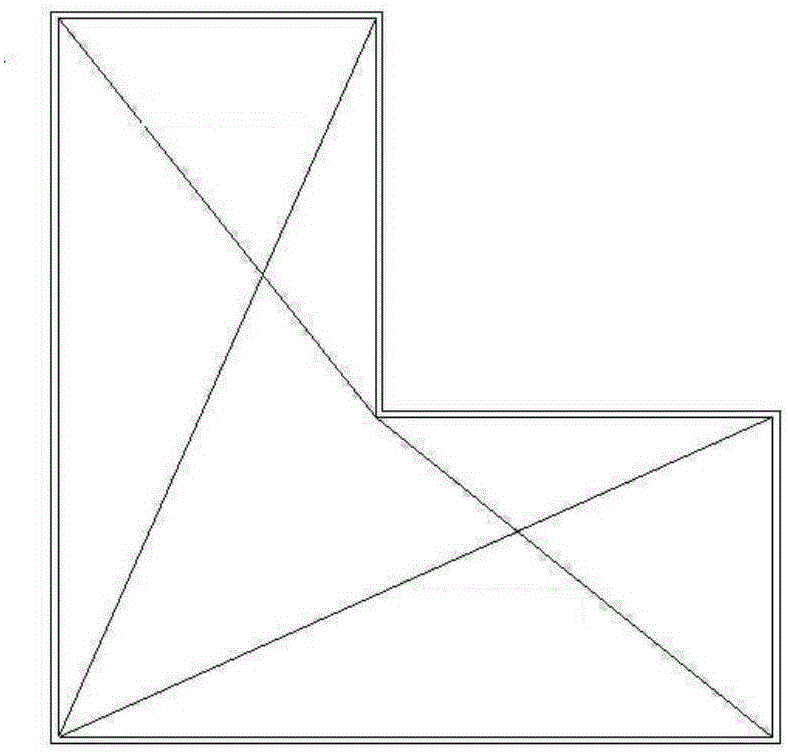

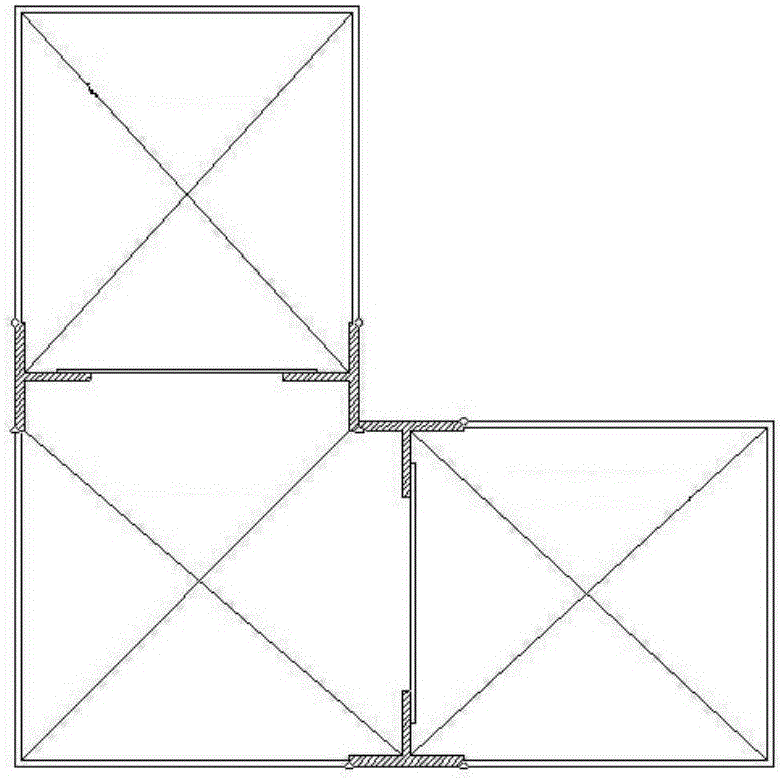

Image

Examples

Embodiment Construction

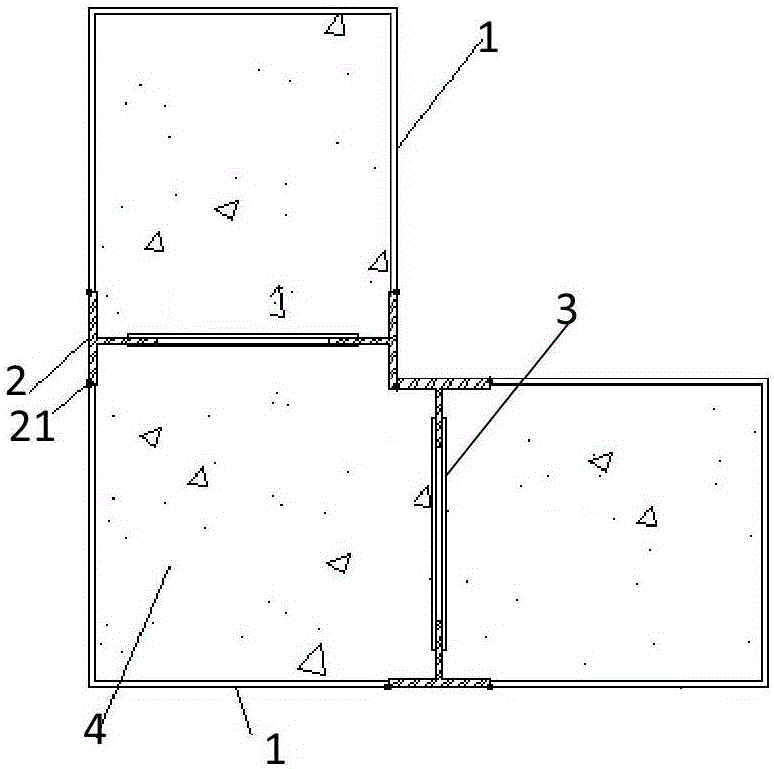

[0019] Such as image 3 , Figure 4a and Figure 4b As shown, the inner truss-type concrete-filled steel tube L-shaped column of the present invention mainly includes the outer-wrapped steel pipe 1, the inner-filled concrete 4 and the inner truss. Among them, the basic components of the inner truss are T-shaped steel 2 and strip 3. In this embodiment, there is a set of T-shaped steel flange plates welded vertically to form an inner truss subunit. In addition, there are 2 T-shaped steels, the webs of these two T-shaped steels are welded with strips, and the other end of the strips is welded to the T-shaped steel webs in the inner truss subunit.

[0020] Such as Figure 4b As shown, an L-shaped frame is formed after welding. In other words, the T-shaped steel and the inner truss subunits 2a are located at the three corners of the quadrangle, or in other words, at the three corners of a quadrangular column. From Figure 4a and Figure 4b It can be seen that there are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com