Cross-shaped steel concrete column stirrup constraint structure and manufacturing method

A cross-shaped steel and concrete column technology, applied in the direction of structural elements, columns, pier columns, etc., can solve the problems of complex construction and low bearing capacity, and achieve the effect of improving bearing capacity, increasing bearing capacity, and reducing the opening ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

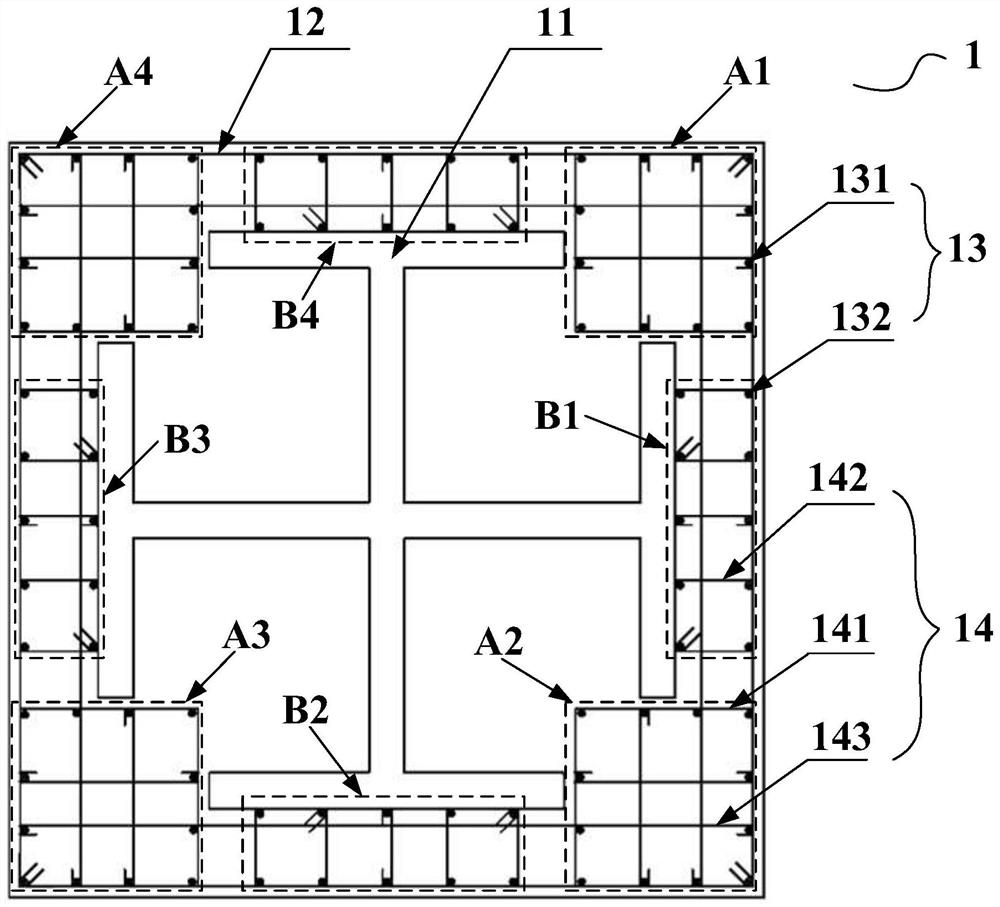

[0038] figure 2 A sectional view of the cross-shaped steel concrete column stirrup restraint structure of the present embodiment is shown; image 3 A plan view of the cross-shaped steel in this embodiment is shown. Such as figure 2 and image 3 As shown, this embodiment proposes a cross-shaped steel concrete column stirrup restraint structure, wherein the cross-shaped steel concrete column 1 includes cross-shaped steel 11, peripheral stirrups 12, longitudinal bars 13 and inner surrounding stirrups 14, wherein,

[0039] The cross-shaped steel 11 is arranged at the center of the cross-shaped steel concrete column 1, the peripheral stirrups 12 are arranged at the periphery of each cross section of the cross-shaped steel concrete column 1, and the longitudinal bars 13 are also arranged at the periphery of the cross-shaped steel concrete column 1 Area, specifically, the longitudinal bars 13 are arranged in the area between the peripheral stirrups 12 and the cross-shaped steel ...

Embodiment 2

[0047] This embodiment proposes a manufacturing method of the cross-shaped steel concrete column stirrup restraint structure in the above-mentioned embodiment 1, comprising the following steps:

[0048] S1. Pouring concrete hollow columns in the concrete rubber mandrel.

[0049] S2. Bind the outer stirrups 12, the longitudinal bars 13, and the inner stirrups 14 constraining the longitudinal bars 13 with nylon cable ties to form a reinforcement cage.

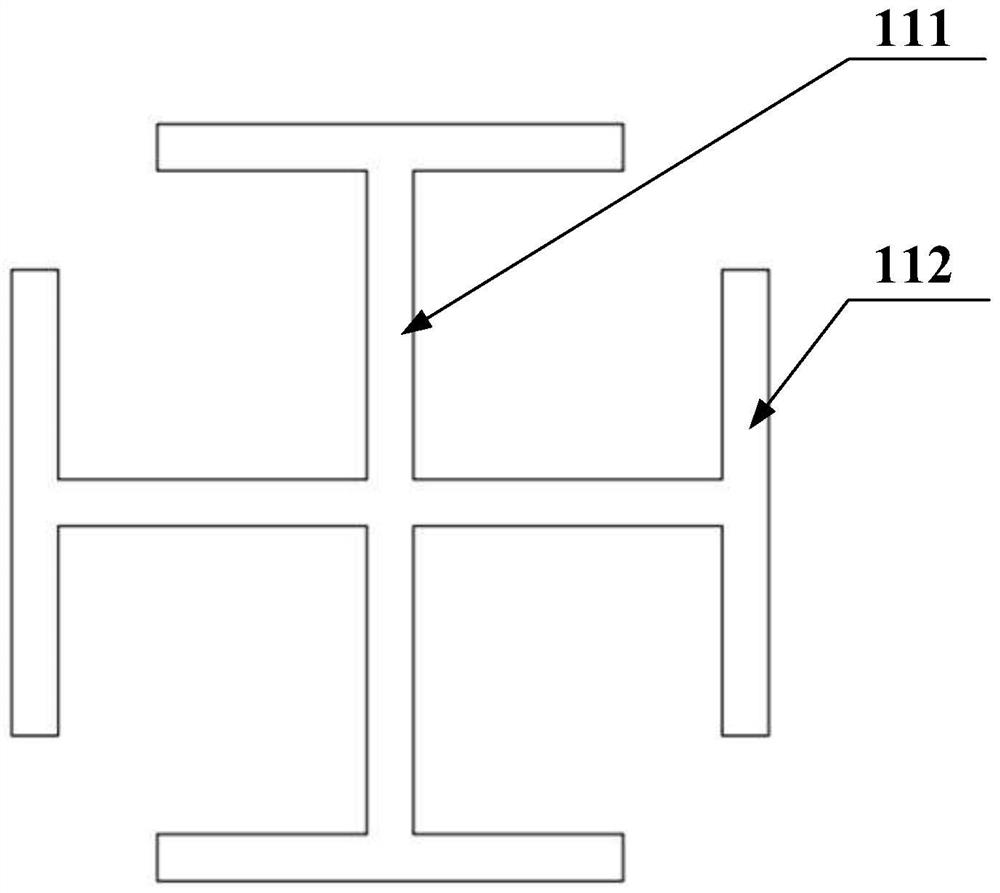

[0050] Specifically, such as image 3 As shown, the cross-shaped steel 11 includes two column webs 111 in an orthogonal crossing and a flange plate 112 arranged at the end of each column web.

[0051] Specifically, such as figure 2 As shown, the longitudinal ribs 13 are divided into four groups of corner longitudinal ribs 131 distributed in a rectangular grid, and four groups of side longitudinal ribs 132 distributed in a rectangle, and the corner restraint stirrups 141 are used to pair the corner longitudinal ribs 131 For bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com