Light-weight orthogonal corrugated core sandwich composite structure and preparation method thereof

A composite structure and corrugated technology, which is applied in the field of lightweight orthogonal corrugated sandwich composite structure and its preparation, can solve the problem of low resistance to local buckling and deformation, and achieve the effect of enhancing the ability of resisting local buckling and avoiding collapse and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

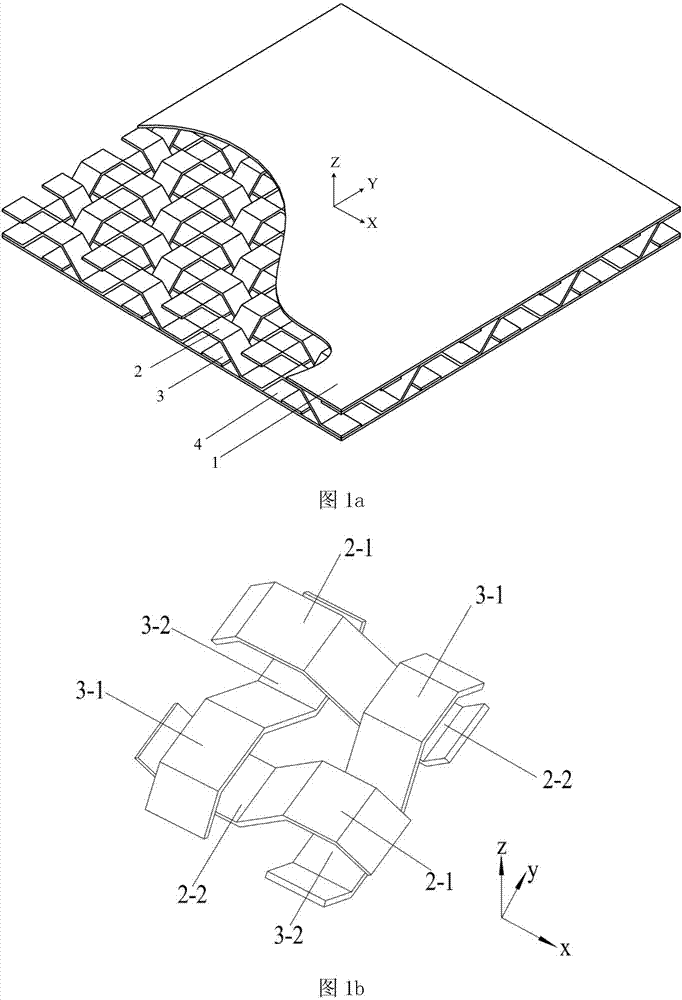

[0027] Such as figure 1 a and figure 1As shown in b, this embodiment is a lightweight orthogonal corrugated sandwich composite structure, including an upper panel 1, a lower panel 4, and an orthogonal corrugated core body arranged between the upper panel 1 and the lower panel 4; the orthogonal corrugated The core is composed of superimposed X-direction corrugated core 2 and Y-direction corrugated core 3; the X-direction corrugated core 2 is a basic unit of the X-direction corrugated core that translates several positive or negative directions along the Y direction. The length of the basic unit; the Y direction corrugated core 3 is composed of the basic unit of the Y direction corrugated core along the positive or negative translation of several basic unit lengths in the X direction; the X direction corrugated core 2 and the Y direction corrugated core 3 The projection planes of the plane XY are perpendicular to each other, the corrugated core body 2 in the X direction and the...

Embodiment 2

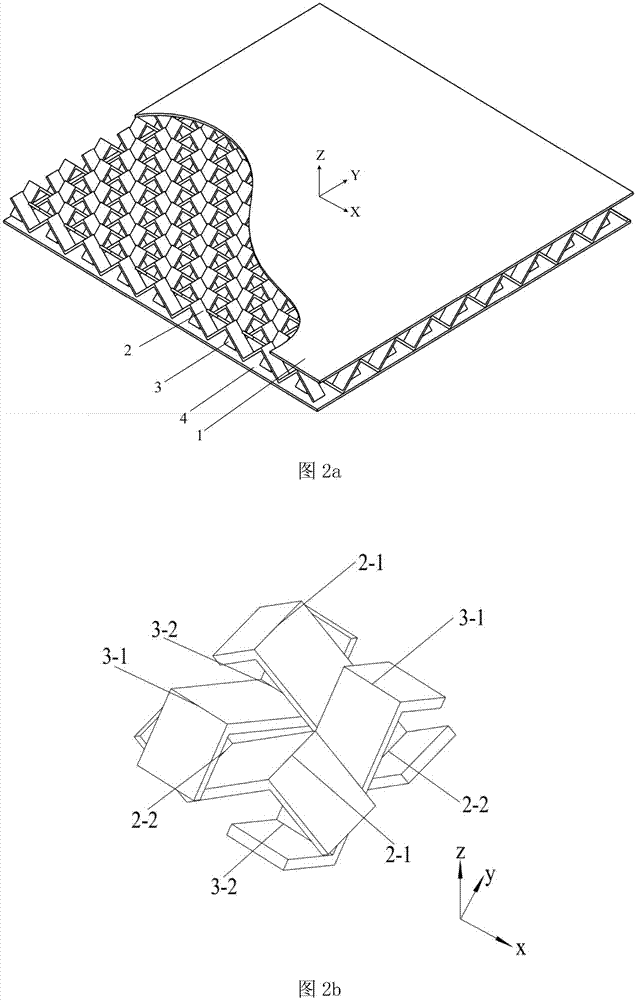

[0030] Such as figure 2 a and figure 2 As shown in b, this embodiment is a light-weight orthogonal corrugated sandwich composite structure, except that the orthogonal corrugated core composed of the X-direction corrugated core 2 and the Y-directed corrugated core 3 is an orthogonal triangular structure. Same as embodiment one.

Embodiment 3

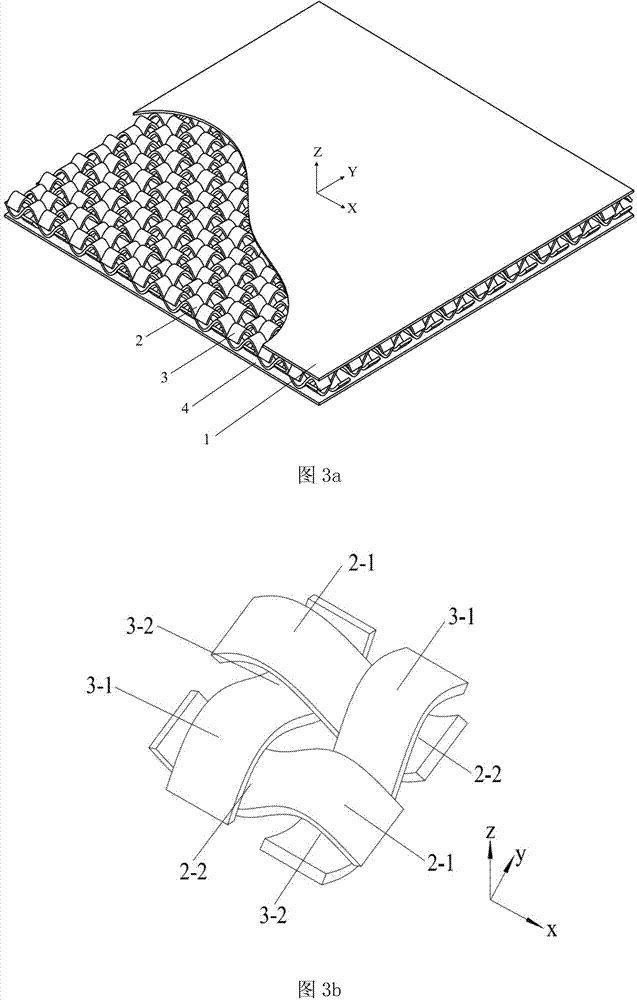

[0032] Such as image 3 a and image 3 As shown in b, this embodiment is a light-weight orthogonal corrugated sandwich composite structure, except that the orthogonal corrugated core composed of the X-direction corrugated core 2 and the Y-directed corrugated core 3 is an orthogonal sinusoidal structure. Same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com