Inner truss system, shape steel-steel pipe concrete cross column and method for constructing same

A technology of concrete filled steel tube and inner truss, applied in columns, piers, pillars, etc., can solve problems such as indoor space occupation, and achieve the effects of enhanced seismic capacity of the structure, high construction efficiency, and improved ductility of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

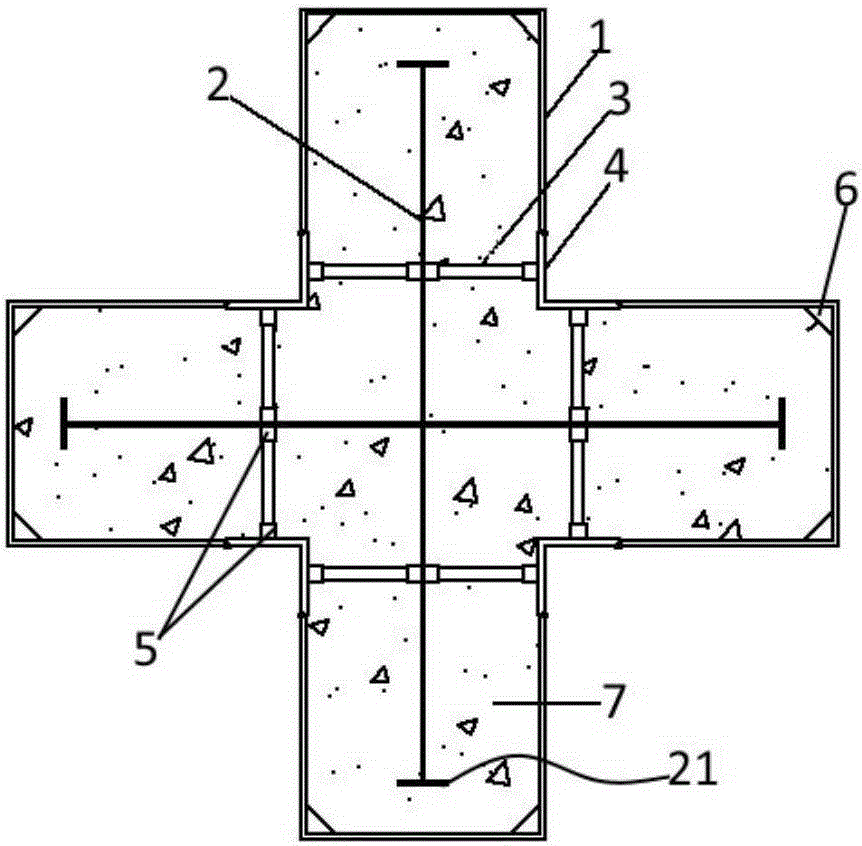

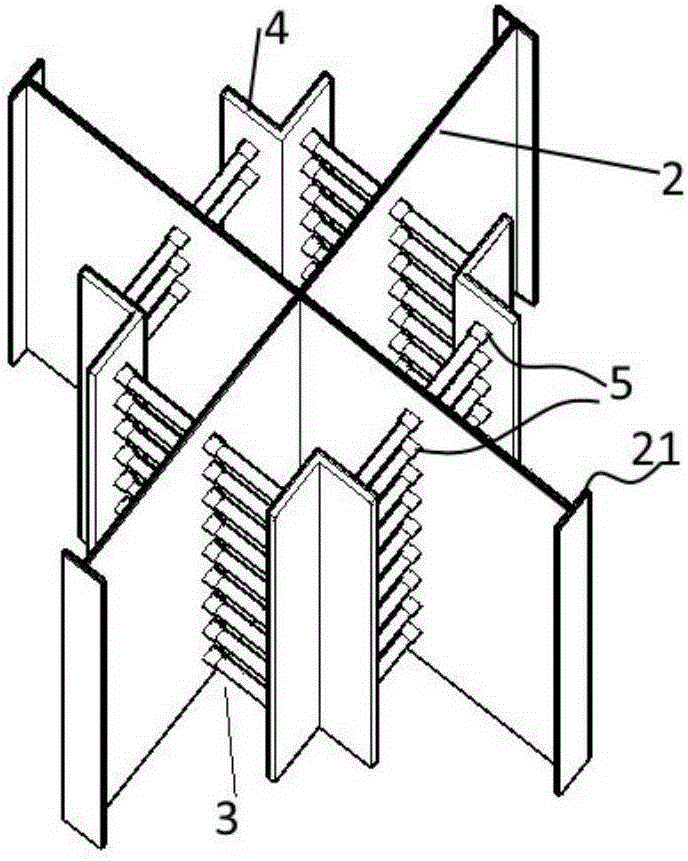

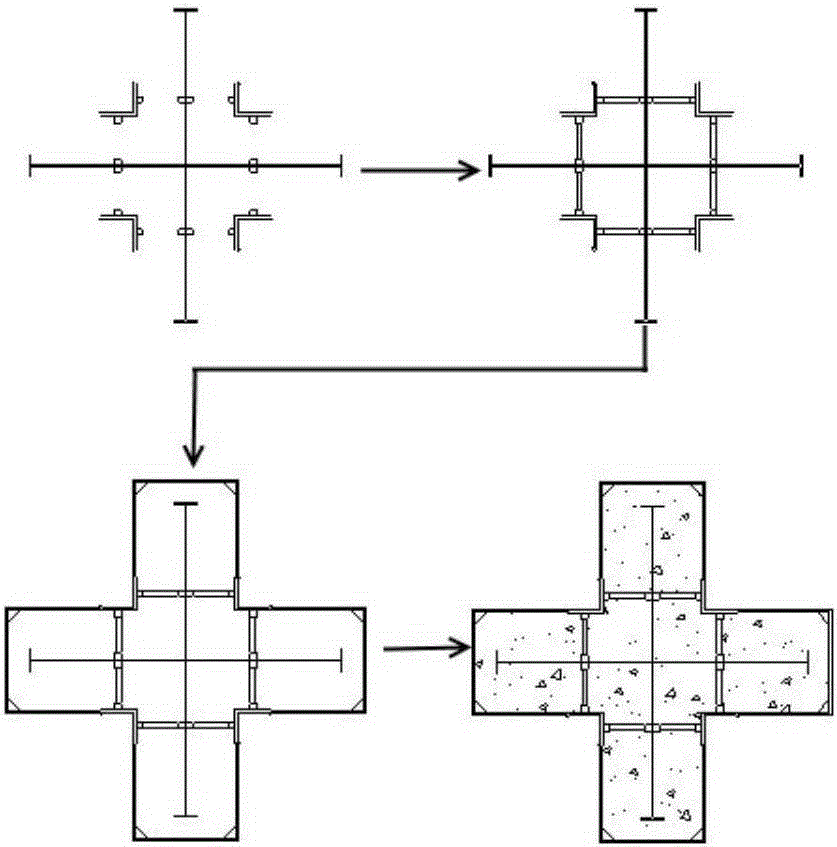

[0020] Such as figure 1 As shown, the steel-steel tube concrete cross-shaped column of the present invention mainly includes the outer steel tube 1, the inner filling concrete 7 and the inner truss system. Among them, the outsourcing steel pipes are four members with ∏-shaped cross-sections, and stiffeners 6 are fixedly connected at the corners. The outer steel pipe is fixedly connected with the inner truss system to form a column with a cross-section. In this column, the section steel is located at the centerline of the column, coincident with the center of the column.

[0021] The inner truss system mainly includes section steel 2, angle steel 4, pressure sleeve 5 and tie rod 3. The cross-section of the shaped steel is cross-shaped, and its webs are perpendicular to each other or on the same plane, and the ends of the webs are provided with flange plates 21 . The cross-section of the angle steel is Γ-shaped, and the number is 4. On the four webs of the profiled steel, sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com