Experimental device for evaluating explosive loading impact safety of tail part of projectile body

An experimental device, the technology of the tail of the projectile, which is used in material inspection products, fuel testing, etc., can solve problems such as no involvement and inability to evaluate the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

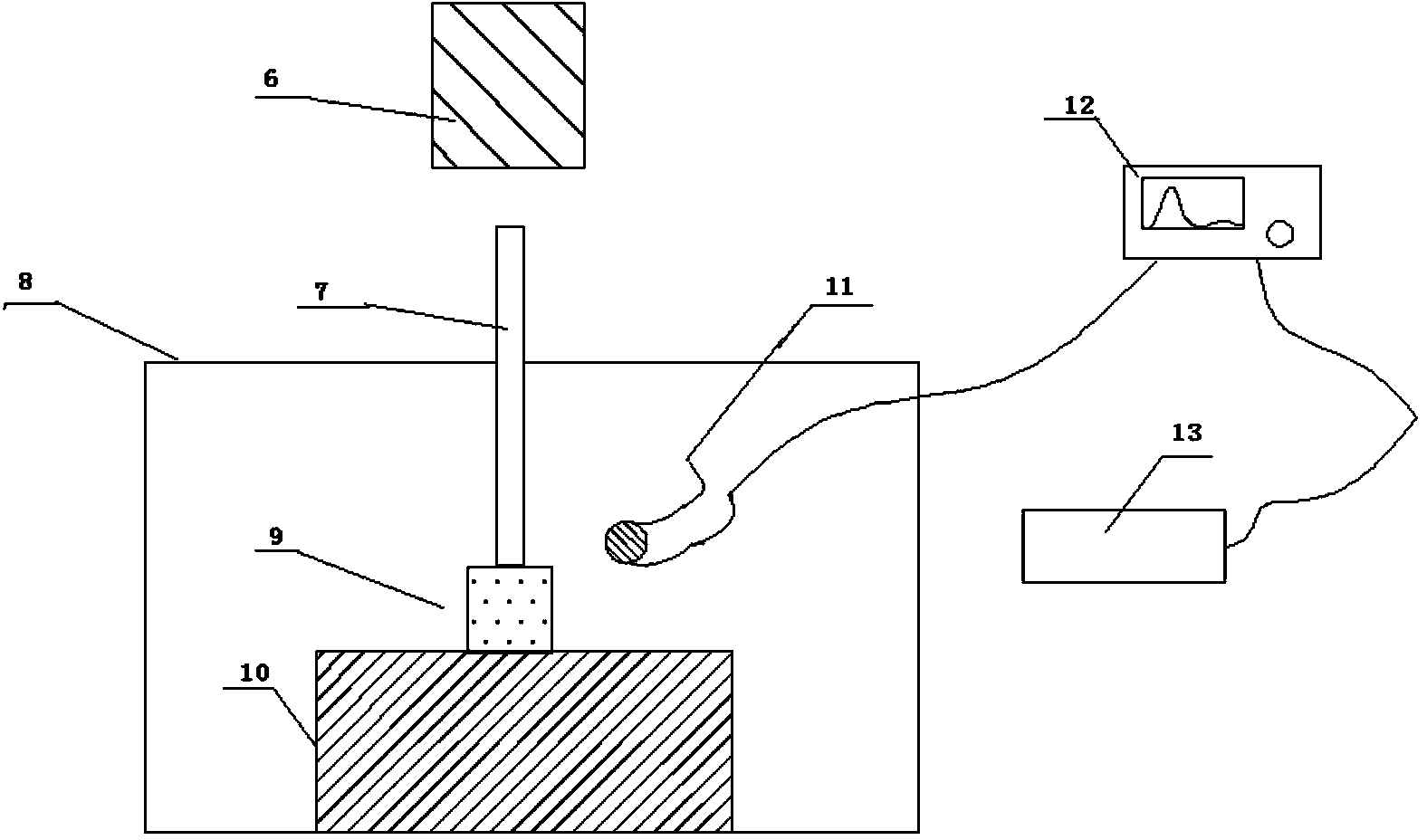

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] (1) Assembly of the present invention

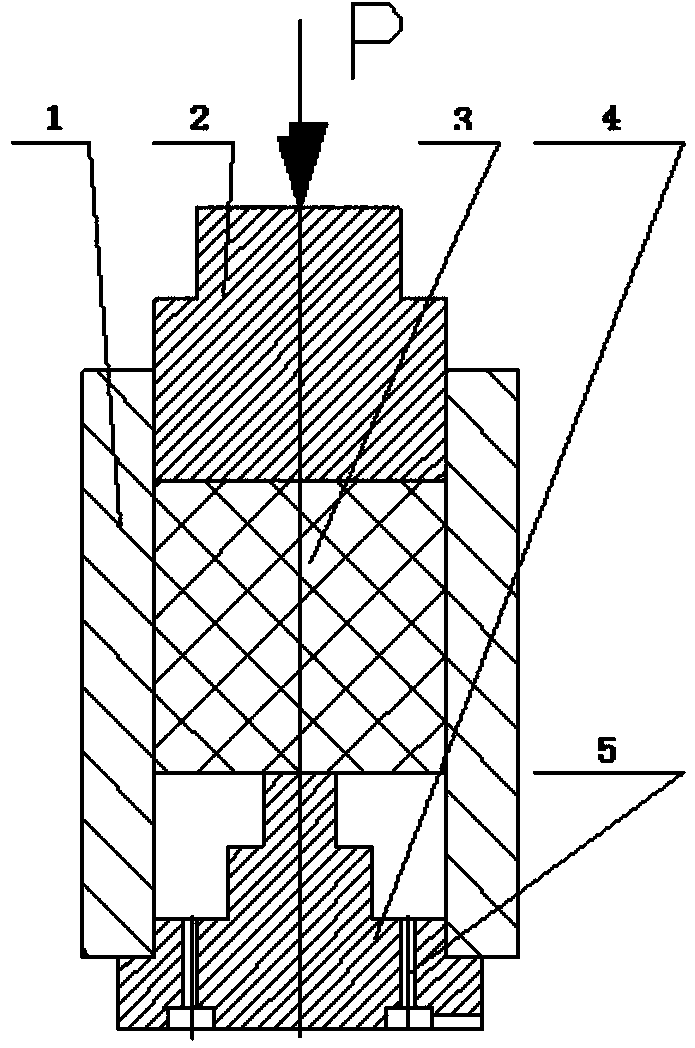

[0011] Such as figure 1 As shown, it is an experimental assembly diagram of applying the present invention to evaluate the impact safety of projectile tail charges. The shearing mold is placed at the bottom of the whole device, and the limiting cylinder is placed on the first step with the largest diameter of the three-level ladder structure of the shearing mold; The top end of the cutting die is in contact; the end with a larger outer diameter of the driving briquetting block is set in the restricting cylinder and contacts the top of the explosive column; the end face of the driving briquetting block with a smaller diameter receives the pressure from the loading source.

[0012] (2) Application of the present invention

[0013] According to the design principle of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com