KBE and WEB technology based stamping design and production system

A technology for manufacturing systems and forging dies, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of affecting design efficiency, unmatched equipment, low equipment utilization, etc., to improve processing efficiency and reliability. performance, shorten the time of mold development, improve the accuracy and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

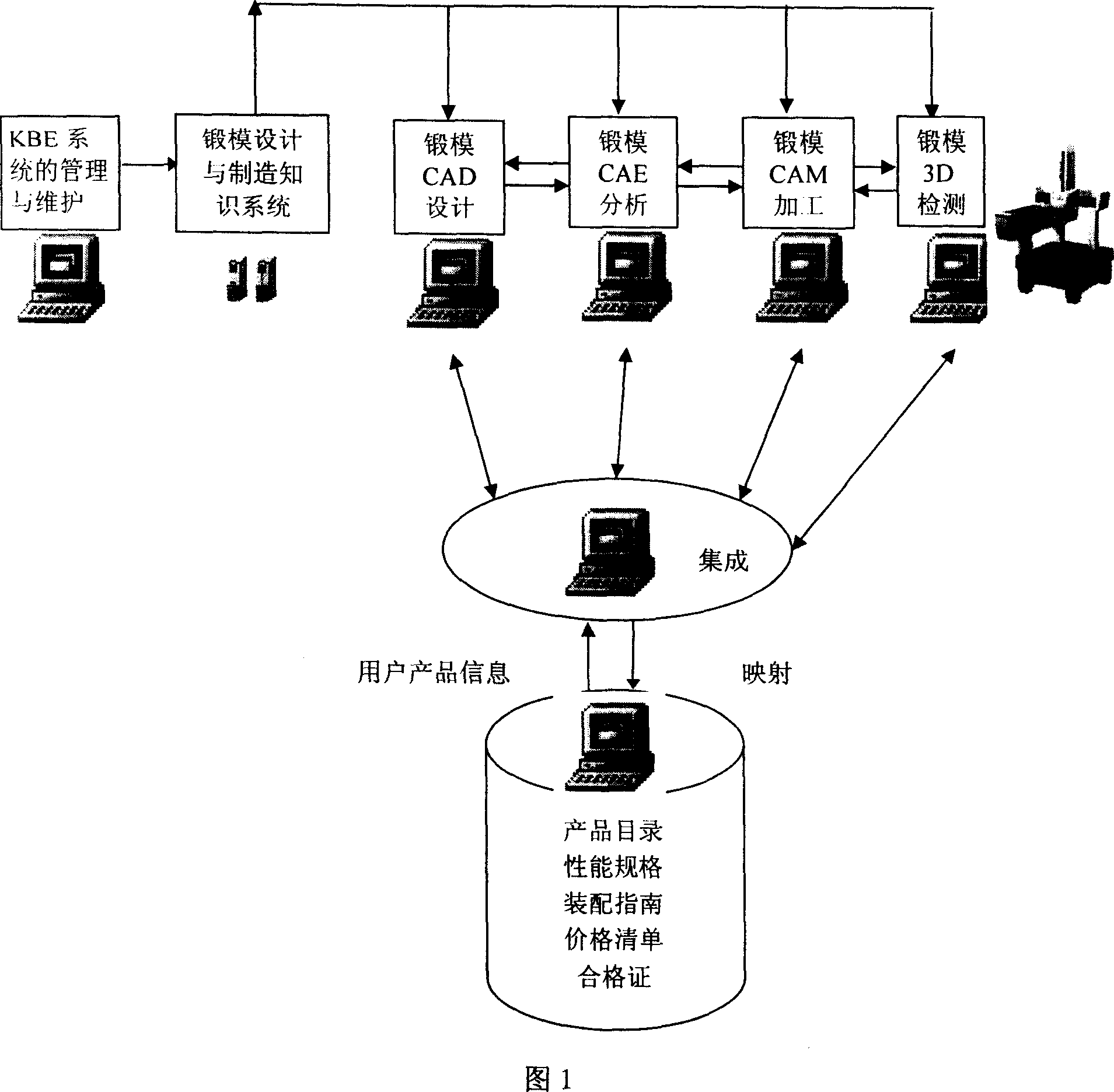

[0053] 1. Forging die design system based on KBE and WEB technology

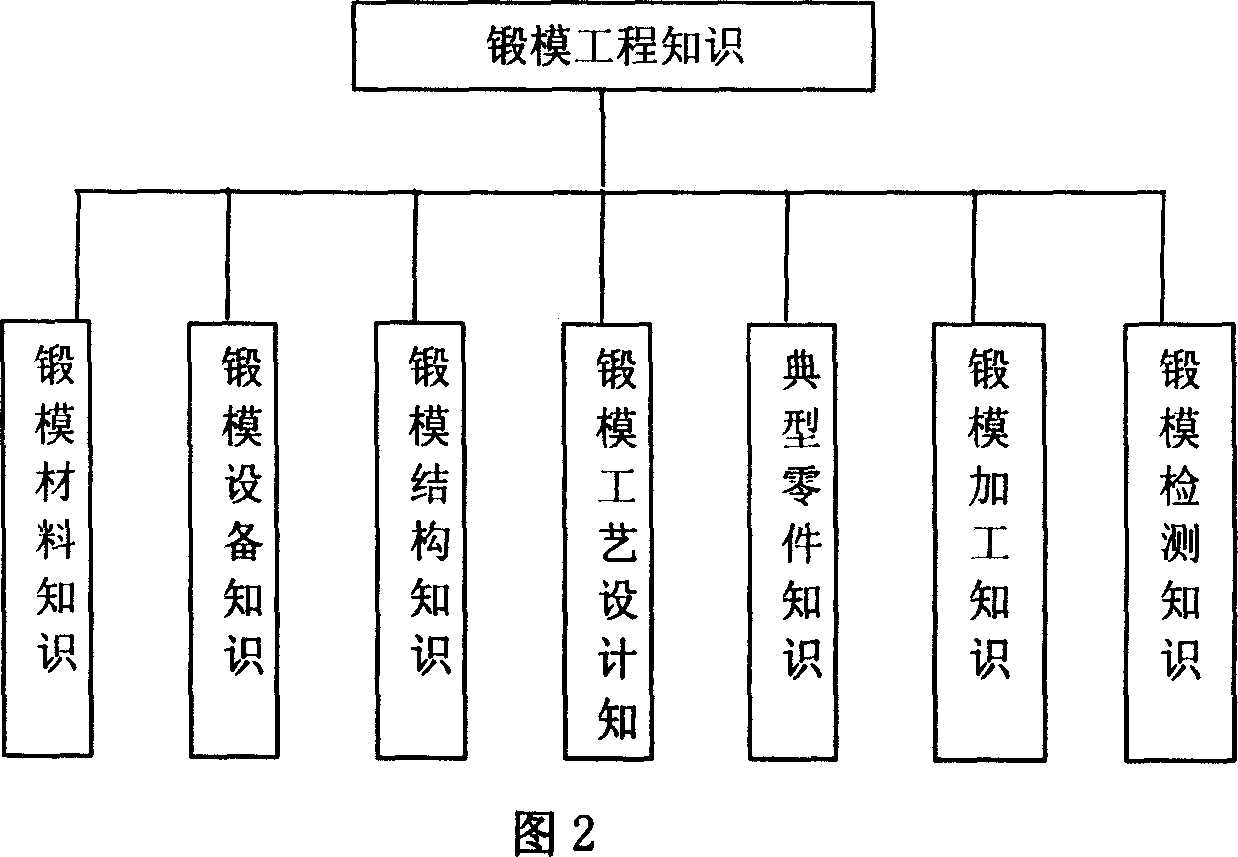

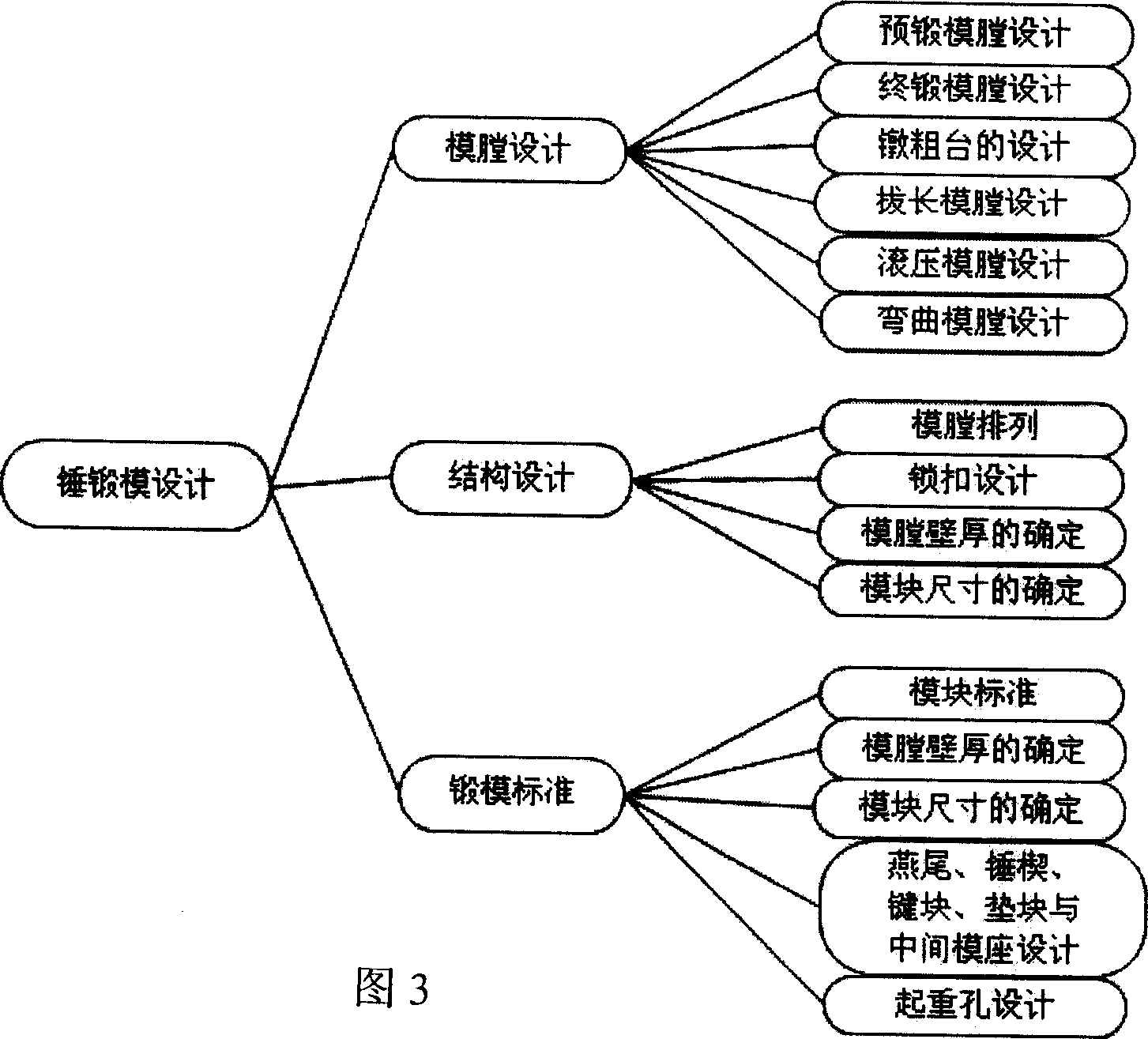

[0054] Referring to Fig. 1, the present invention takes general-purpose CAD / CAM / CAE software UG NX2.0, MASTERCAM, and DEFORM as basic design and manufacturing platforms, and adopts collaborative engineering, KBE technology and optimization methods for forging die CAE experience knowledge and high-speed machining knowledge , Three-coordinate detection knowledge, mold reuse knowledge, etc. are collected, sorted, combined, etc., and integrated into a module by using computer programs. Finally, based on the LAN WEB technology, knowledge system, CAD design, CAE analysis, CAM processing, 3D detection and other software and hardware are connected together to form a complete system with collaborative functions, which becomes a working platform for design and manufacturing. Each process of the forging die design and manufacturing work platform accepts the user's product information requirements and completes its own ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com