Connecting joint of ring beam of steel core concrete column used for topdown construction method foundation pit engineering

A technology for concrete-filled steel tubular columns and connecting nodes, which is used in infrastructure engineering, columns, piers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

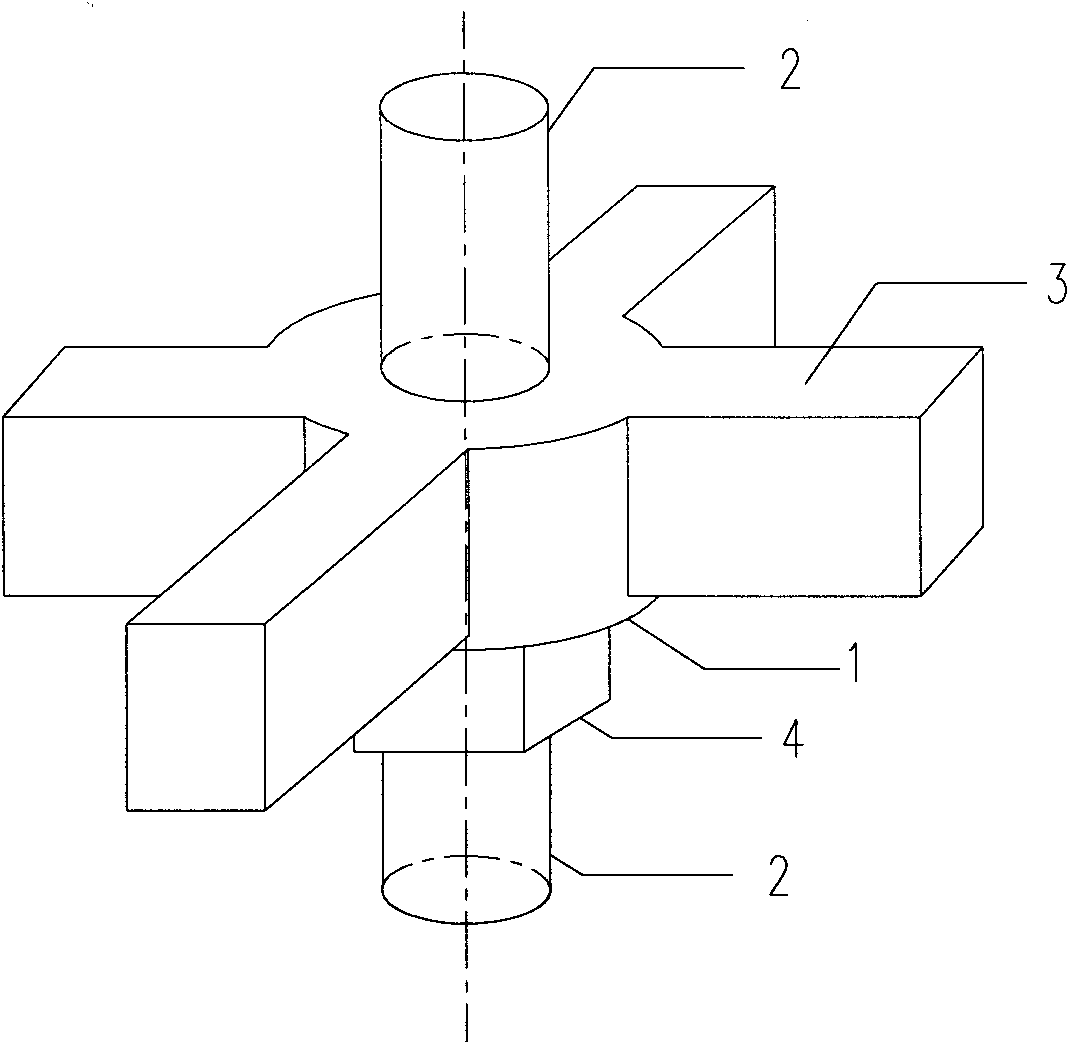

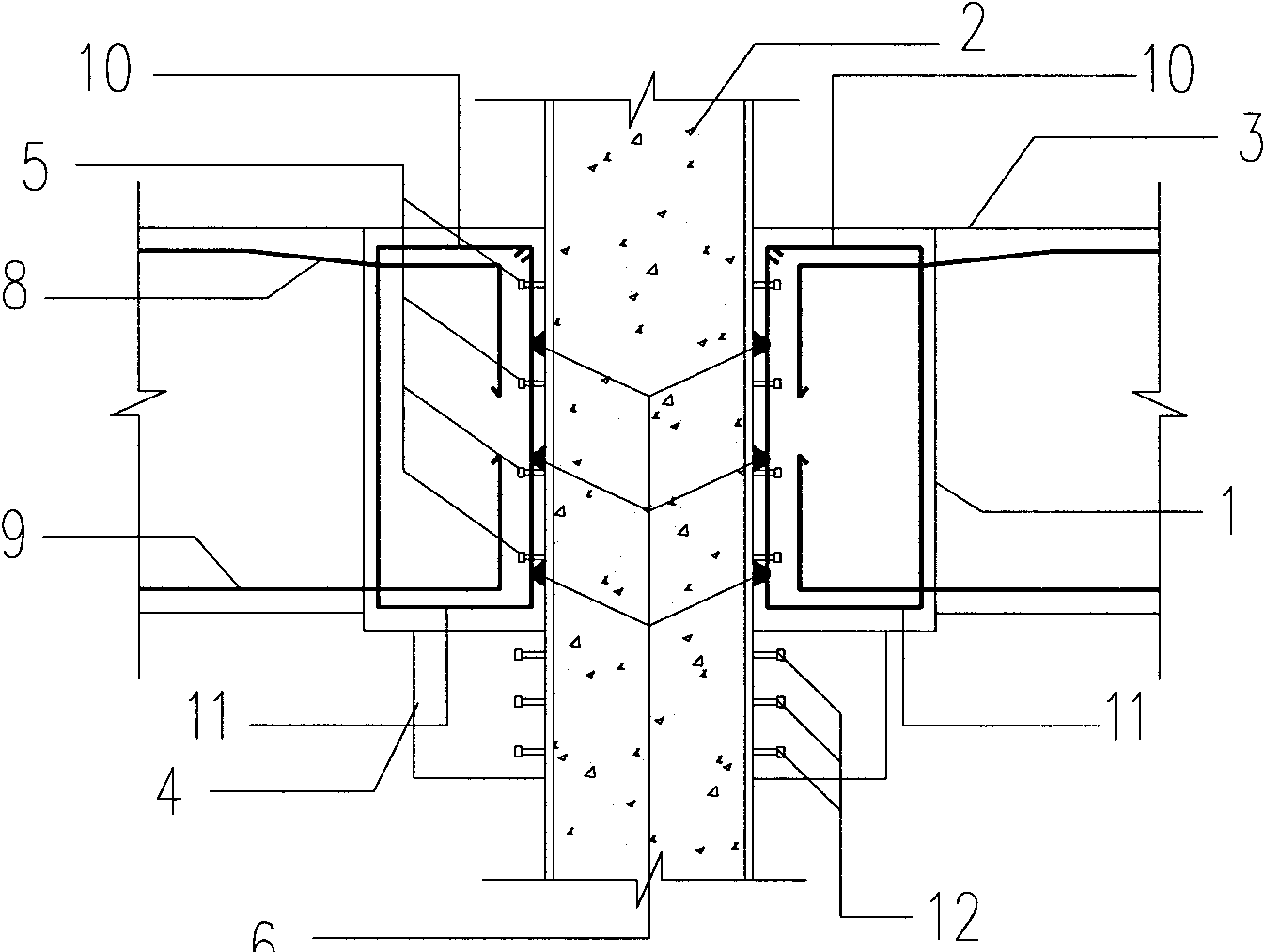

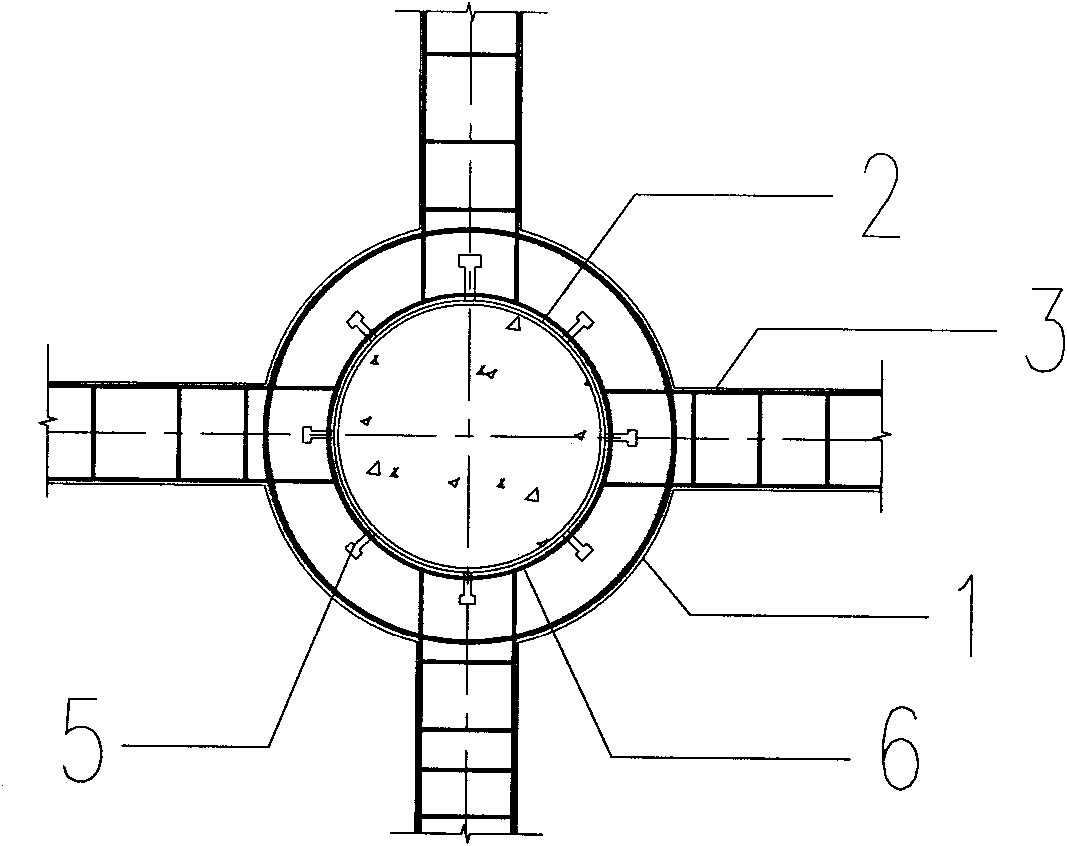

[0018] Such as figure 1 , 2 As shown in and 3, 1 is the reinforced concrete ring beam, 2 is the steel pipe concrete column, 3 is the underground structural beam constructed during the implementation of the reverse method, 4 is the end of the column constructed during the implementation of the reverse method, and 5 is the steel pipe concrete The studs at the connection between the column and the reinforced concrete ring beam, 6 is the ring bar, 8 is the longitudinal steel bar at the top of the underground structural beam, 9 is the longitudinal steel bar at the bottom of the underground structural beam, 10 is the top steel bar of the reinforced concrete ring beam, and 11 is the reinforced concrete ring beam Bottom reinforcing bar, 12 is the end connection stud of column end and the end connection place of steel tube concrete column. The invention can be applied to the mid-span beam-slab joint of the basement, and can also be applied to the steel pipe concrete column-beam-column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com