Linear steel tube bundle composite structure

A technology of combined structure and steel tube bundle, applied in the direction of structural elements, elongated structural components used for load-bearing, building components, etc., can solve the problems of complex component production, difficult construction, and a lot of labor, and achieve reliable product quality and division. Flexible, fast production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

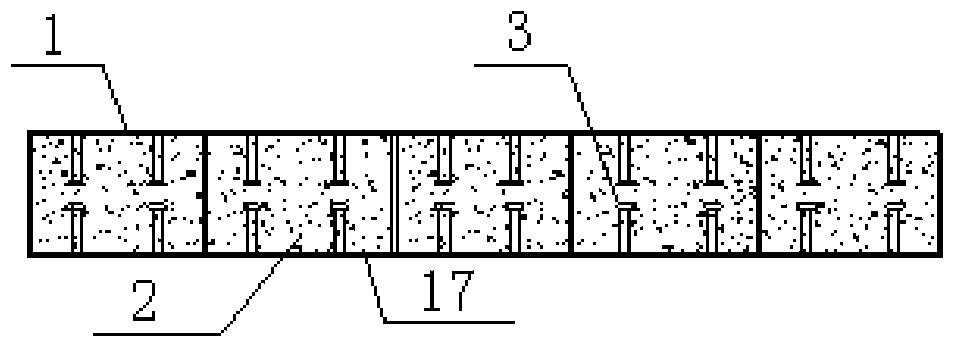

[0041] refer to Figure 1 to Figure 7 , a kind of in-line steel pipe bundle combined structure, is made of linear steel pipe bundle assembly 1, and described linear steel pipe bundle assembly 1 is formed by connecting successively with a plurality of steel pipe units 17; Described steel pipe unit 17 has hollow Cavity, pouring concrete 2 in the cavity.

[0042] Further, pegs 3 are arranged on the side walls of the cavity.

[0043] Further, through holes are provided on the partitions between adjacent steel pipe units 17 .

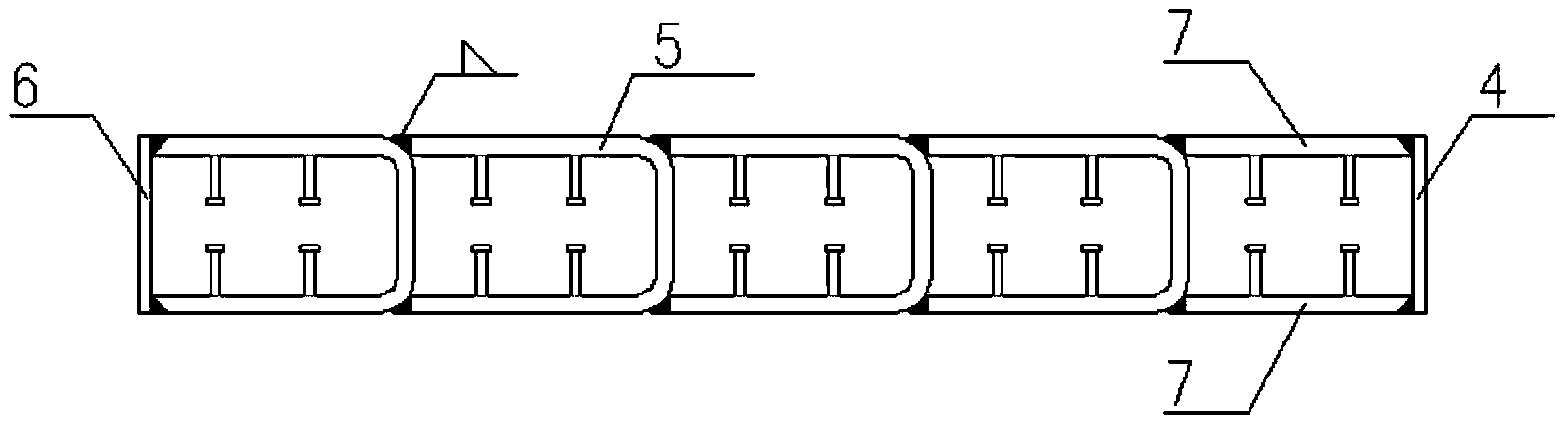

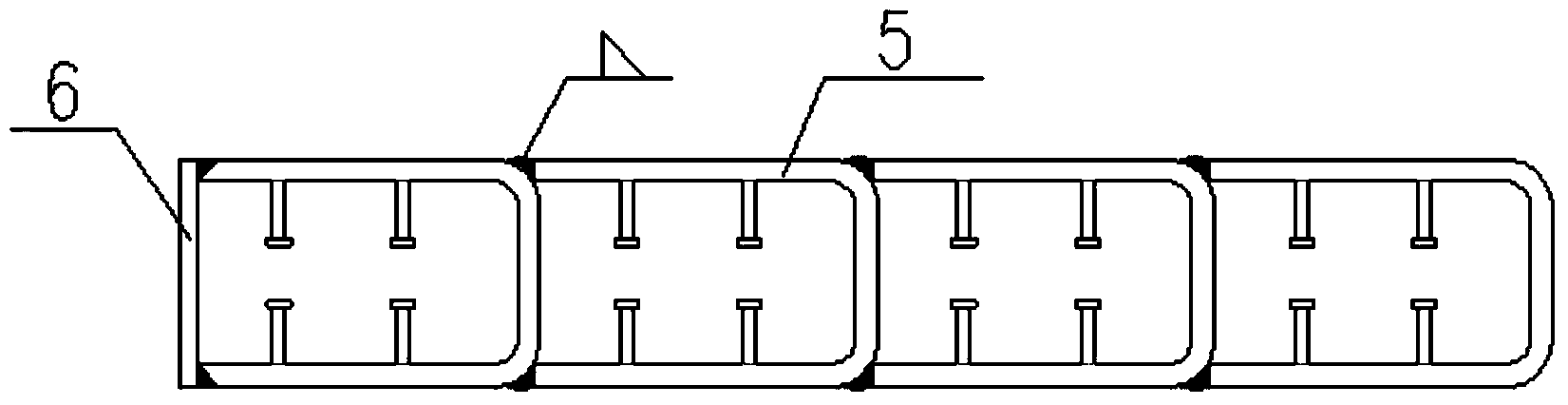

[0044] Further, the steel pipe unit 17 is spliced by steel pipes 5 with a U-shaped cross section, and the U-shaped opening of each steel pipe unit is spliced with the U-shaped bent bottom of the previous steel pipe;

[0045] The U-shaped open end of the steel pipe unit at the front end is sealed and welded by a steel plate 6 or a box-shaped member 18, and the steel pipe unit at the rear end is closed and welded by two side plates 7 and a bottom plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com