Closed metal support structure and construction method thereof

A metal support and component technology, which is used in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve problems such as low shear bearing capacity and shear buckling strength of webs, difficulty in meeting support requirements, and incompatibility in deformation. , to achieve the effect of good stability, convenient installation and simple production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, structure of the present invention, construction process are described further.

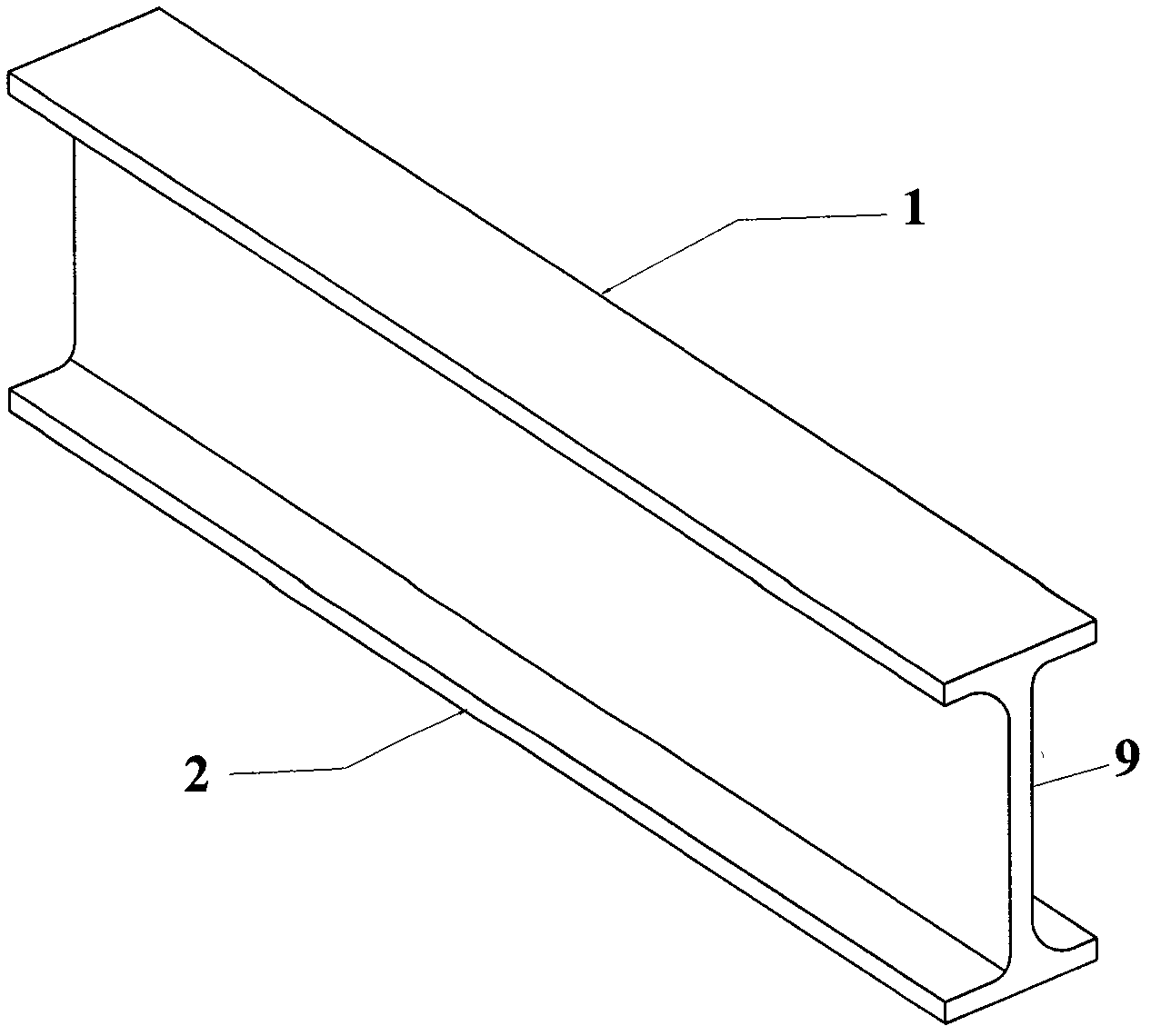

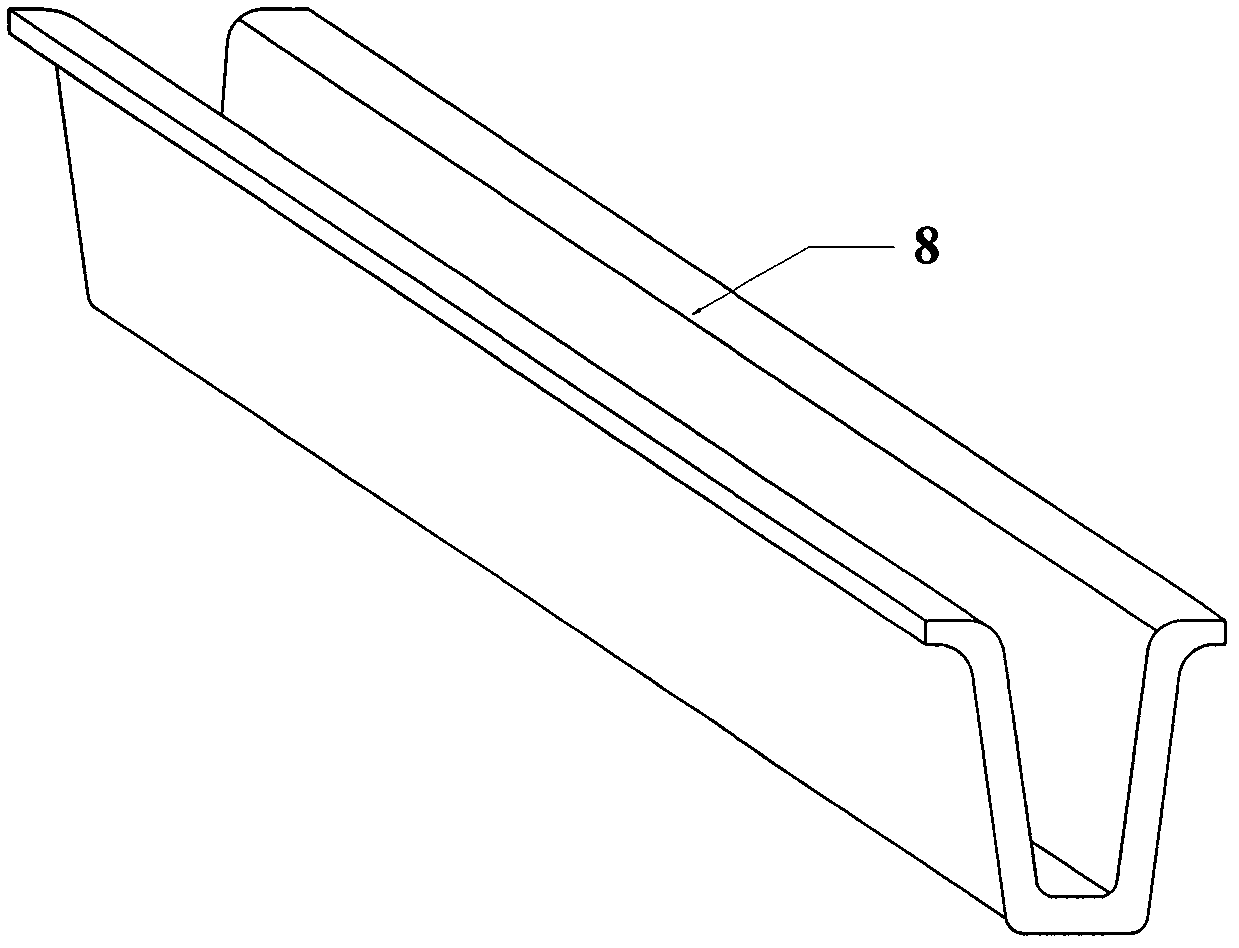

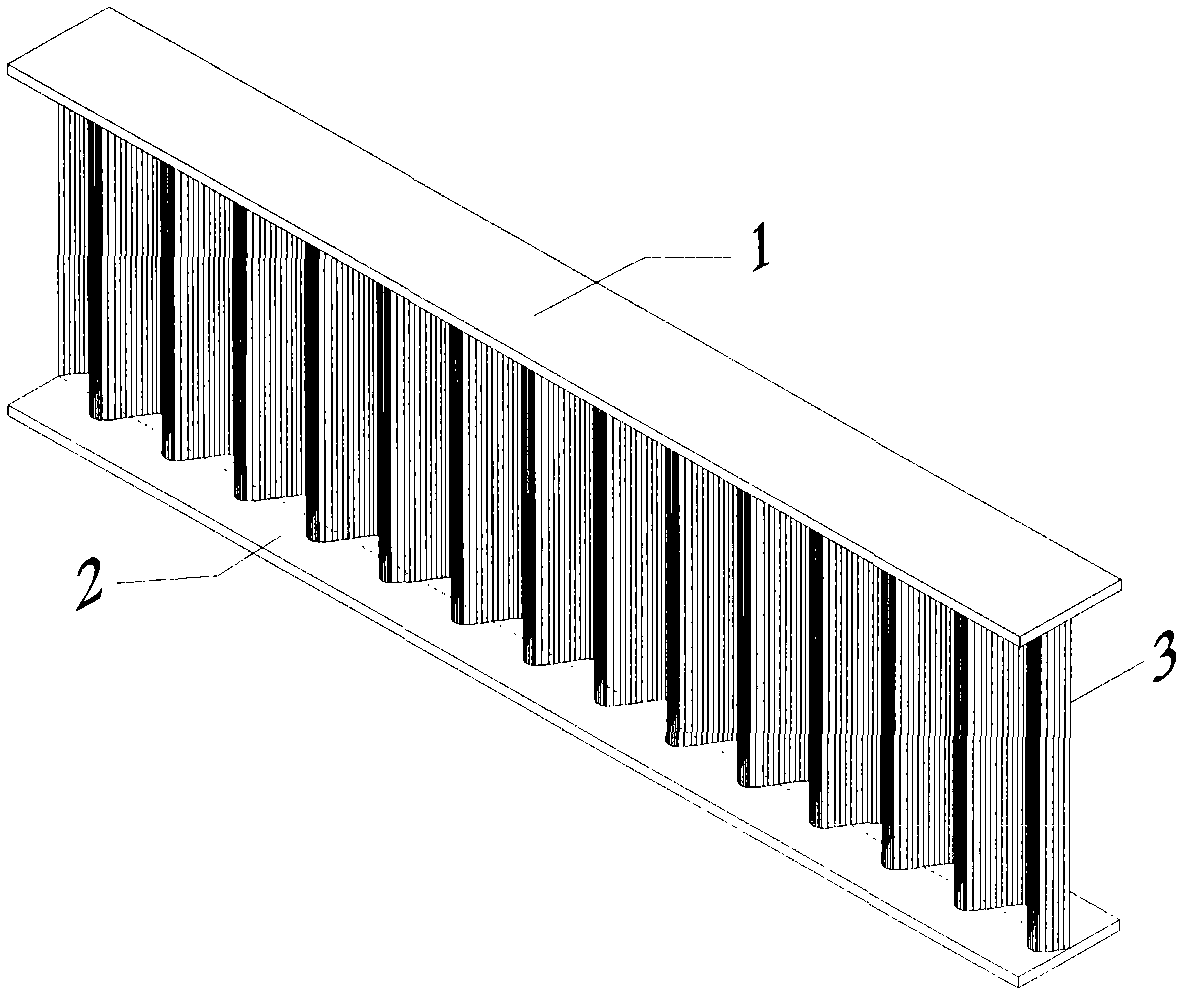

[0022] The invention provides a closed metal support structure with a corrugated steel web I-shaped cross-section, which can improve the bearing capacity of the supporting structure of the soft rock tunnel (roadway) and can adapt to the large deformation characteristics of the surrounding rock of the soft rock tunnel (roadway). Such as image 3 and Figure 5 As shown, the corrugated web I-shaped member consists of an upper flange 1, a lower flange 2 and a corrugated steel web 3. The corrugated steel web 3 is welded to the upper flange 1 and the lower flange 2 respectively. After the I-shaped member is bent into the shape required by the bracket, the corrugated steel web 3 is connected to the first connecting end plate 4 and the second connecting end plate 4 through welds respectively. The end plate 7 is connected, and the upper flange 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com