External transverse prestressed steel reinforced concrete beam

A reinforced concrete beam, transverse prestressing technology, applied in the direction of joists, girders, truss beams, etc., to achieve the effect of improving shear resistance, shear bearing capacity and shear resistance, and shear bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

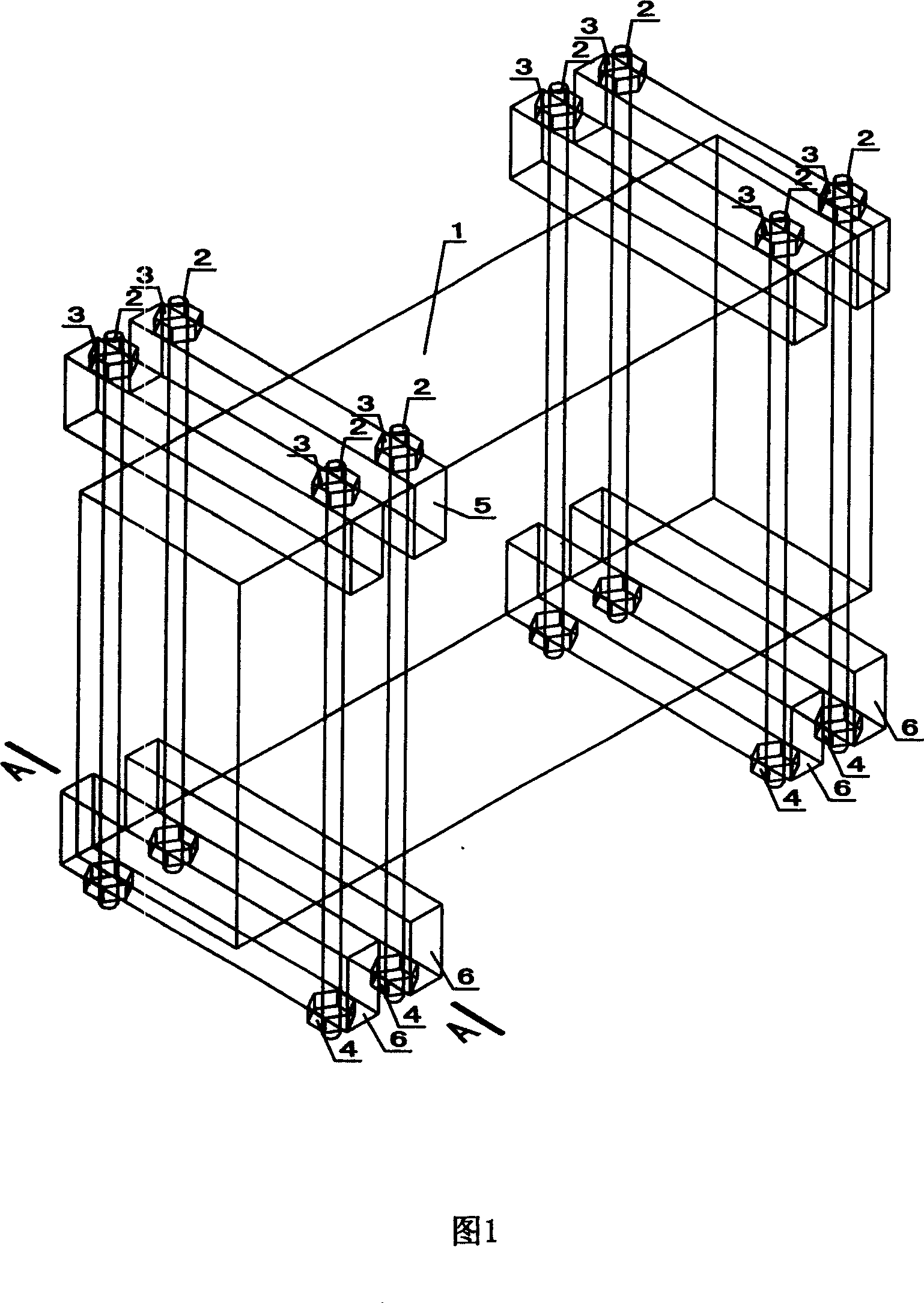

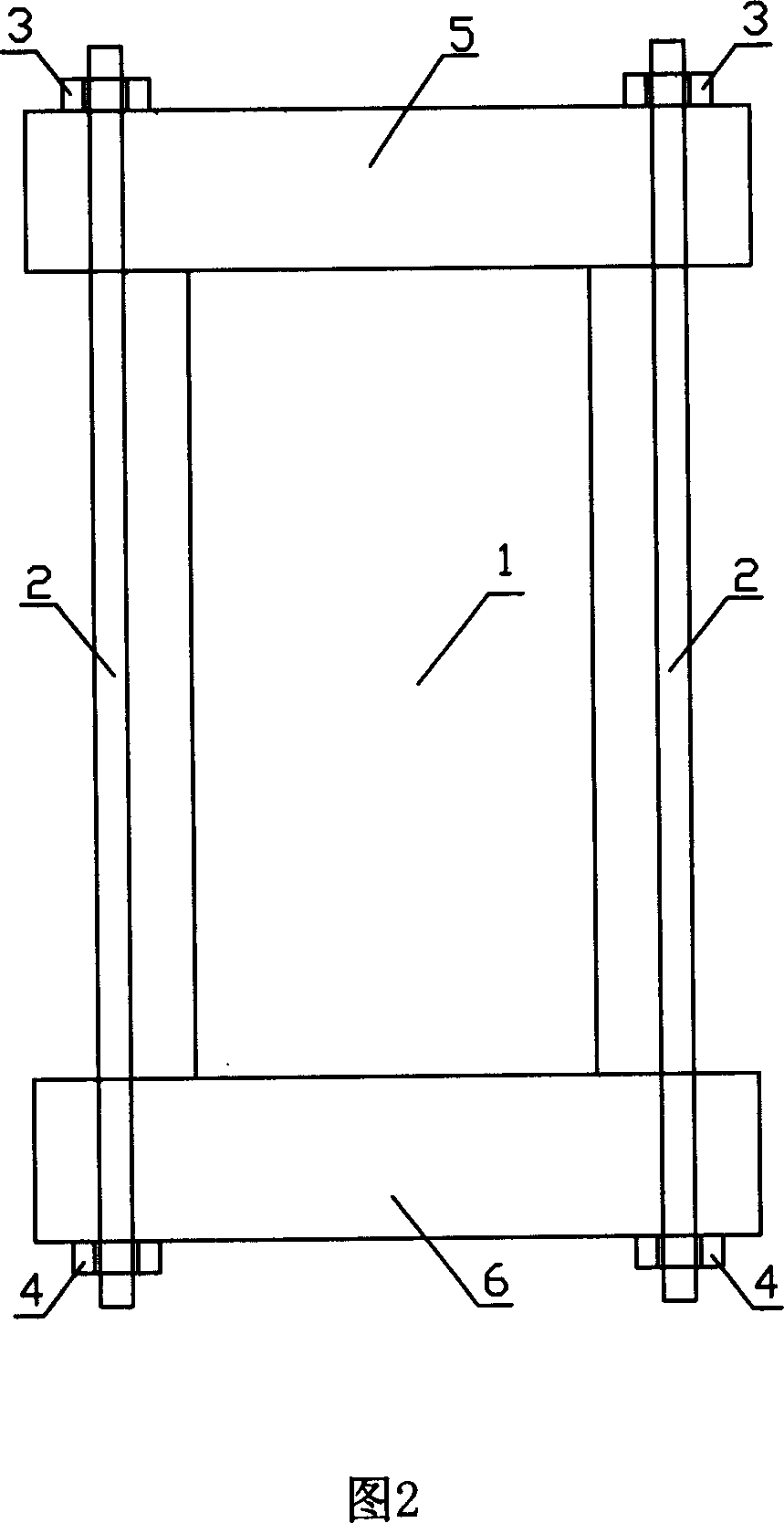

[0022] As shown in Figures 1, 2 and 3, an external transverse prestressed reinforced concrete beam includes a reinforced concrete beam 1, a tie rod 2, an upper anchor 3, a lower anchor 4, an upper pressure piece 5 and a lower pressure piece 6. Four upper pressing pieces 5 and lower pressing pieces 6 are respectively arranged on the upper surface and the lower surface of the reinforced concrete beam 1, the length of the upper pressing piece 5 and the lower pressing piece 6 are greater than the width of the reinforced concrete beam 1, and both ends of the upper pressing piece 5 and the lower pressing piece 6 are arranged along the The concrete beam 1 protrudes in the width direction, and the upper pressing part 5 and the lower pressing part 6 are provided with a row of holes on both sides of the width direction of the reinforced concrete beam 1, and the tie rod 2 passes through the upper pressing part on the two outer sides of the reinforced concrete beam 1 width. A piece 5 and a...

Embodiment 2

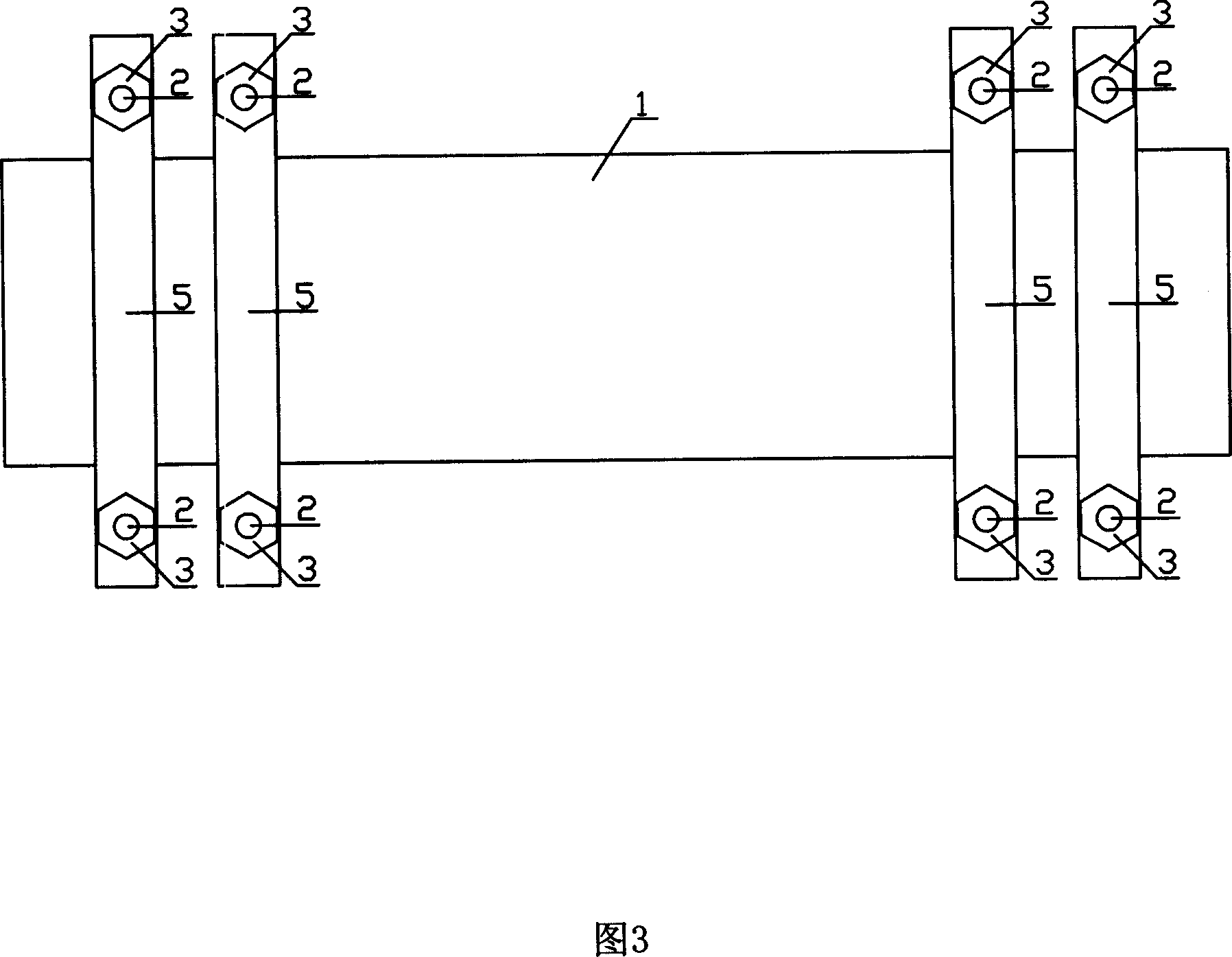

[0028] Considering that the bearing capacity of the original reinforced concrete transfer beam is quite different from the actual needs, by increasing the number of tie rods 2, the method of increasing the number of rows and columns of tie rods is adopted. In this embodiment, six upper pressing pieces 5 and lower pressing pieces 6 are respectively arranged symmetrically on the upper surface and the lower surface of the reinforced concrete beam 1, and each upper pressing piece 5 and lower pressing piece 6 are arranged in the width direction of the reinforced concrete beam 1. A row of tunnels are arranged on both sides of the exterior. The tie rod 2 passes through the upper pressing part 5 and the lower pressing part 6 on the two outer sides of the width of the reinforced concrete beam 1. After the tie rod 2 is tightened, it passes through the upper anchorage 3 and the The lower anchorage 4 is fixed between the upper pressing piece 5 and the lower pressing piece 6, and the streng...

Embodiment 3

[0030] If the height of the original reinforced concrete transfer beam is limited, but the tie rod 2 needs to be longer to avoid excessive prestress loss, the tie rod 2 should be arranged obliquely. As shown in Figure 5, a row of tunnels are arranged on the outer sides of the reinforced concrete beam 1 in the width direction of the upper pressure piece 5 and the lower pressure piece 6, and the holes on the upper pressure piece 5 and the lower pressure piece 6 are not in the same vertical direction. On the line, but staggered by a certain distance, facing diagonally. In this way, the tie rod 2 and the bottom surface of the reinforced concrete beam 1 pass through the upper pressing part 5 and the lower pressing part 6 at an angle. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com