Steel tube concrete - steel support - steel plate external wrapping concrete shear force wall and manufacturing method thereof

A technology of steel pipe concrete and outsourcing concrete, which is applied to walls, building components, and earthquake resistance. It can solve problems such as poor ductility and influence on lateral force resistance, achieve slow decay of bearing capacity and stiffness, and improve shear bearing capacity and bearing capacity. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

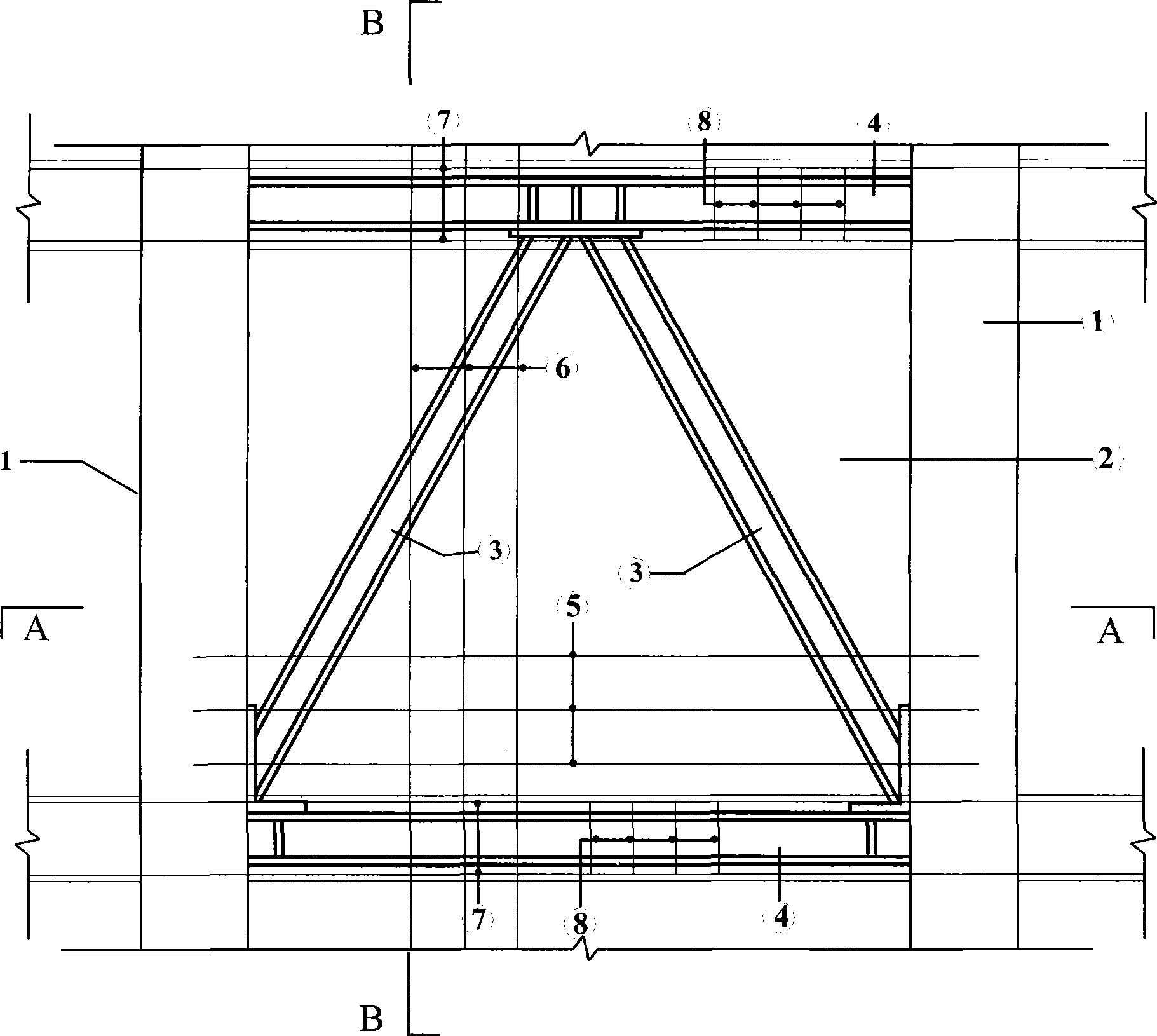

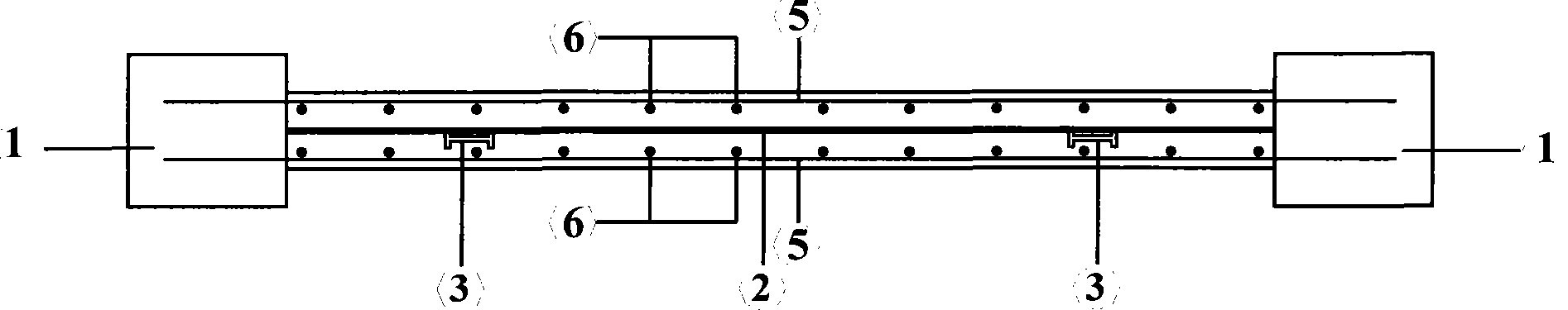

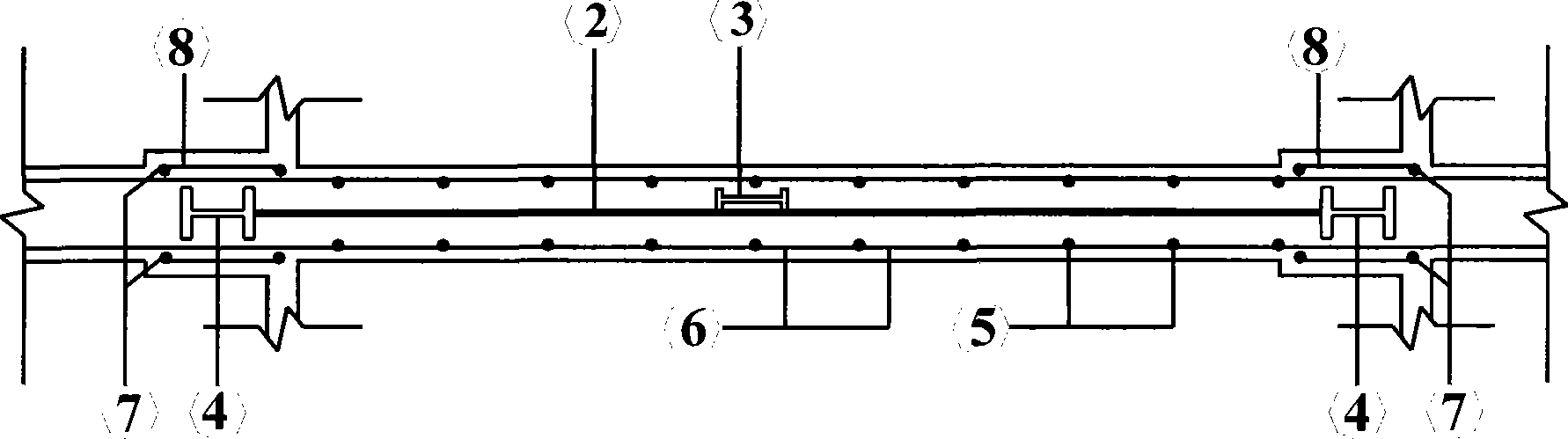

[0032] Schematic diagram of the structural reinforcement of a structural unit of steel tube concrete-steel braces-steel plate-wrapped concrete shear wall is as follows figure 1 , figure 2 and image 3 shown.

[0033] The production method is as follows:

[0034] 1) Fabricate steel pipe concrete frame column 1, install partitions inside steel pipes at beam-column joints, weld short steel beams outside the columns, and pre-weld vertical plates on steel pipe walls to prepare for anchoring steel plates 2 embedded in wall panels, and reserve The hole is used for anchoring the transverse reinforcement 5;

[0035] 2) Make the profiled steel beam 4 in the frame beam, the edge of the profiled steel beam 4 is welded to the flange of the preset short steel beam at the column edge, and the web of the steel beam and the web of the short steel beam are rubbed with double splint high-strength bolts type connection;

[0036] 3) Making the steel plate 2 embedded in the wall panel, the st...

Embodiment 2

[0043] The second structural form of steel tube concrete-steel braces-steel plate-wrapped concrete shear walls is as follows: Figure 4 As shown, an X-shaped steel brace 3 is set on the steel plate 2, and its upper end is connected with the steel pipe concrete frame column 1 and the upper steel beam 4 at the same time. The lower end is connected with the steel pipe concrete frame column 1 and the lower shaped steel beam 4 at the same time. Other aspects are the same as the first form.

Embodiment 3

[0045] The third structural form of steel tube concrete-steel braces-steel plate-wrapped concrete shear walls is as follows: Figure 5 Shown, be that a figure-eight shaped steel brace 3 is set on the steel plate 2, and its upper end is connected with the upper shaped steel beam 4. The lower end is connected with the steel pipe concrete frame column 1 and the lower shaped steel beam 4 at the same time. Other aspects are the same as the first form. Embodiment 4, 5, 6

[0046] When the height-to-width ratio of the shear wall is less than 1, it is better to adopt multiple composite concealed support network layout. The fourth, fifth and sixth structural forms of steel tube concrete-steel braces-steel plate-wrapped concrete shear walls are as follows: Figure 6 , Figure 7 , Figure 8 As shown, the height-to-width ratio of the shear wall is less than 1 at this time, and the steel brace in the wall panel can be selected from one of the above three methods, and the other structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com