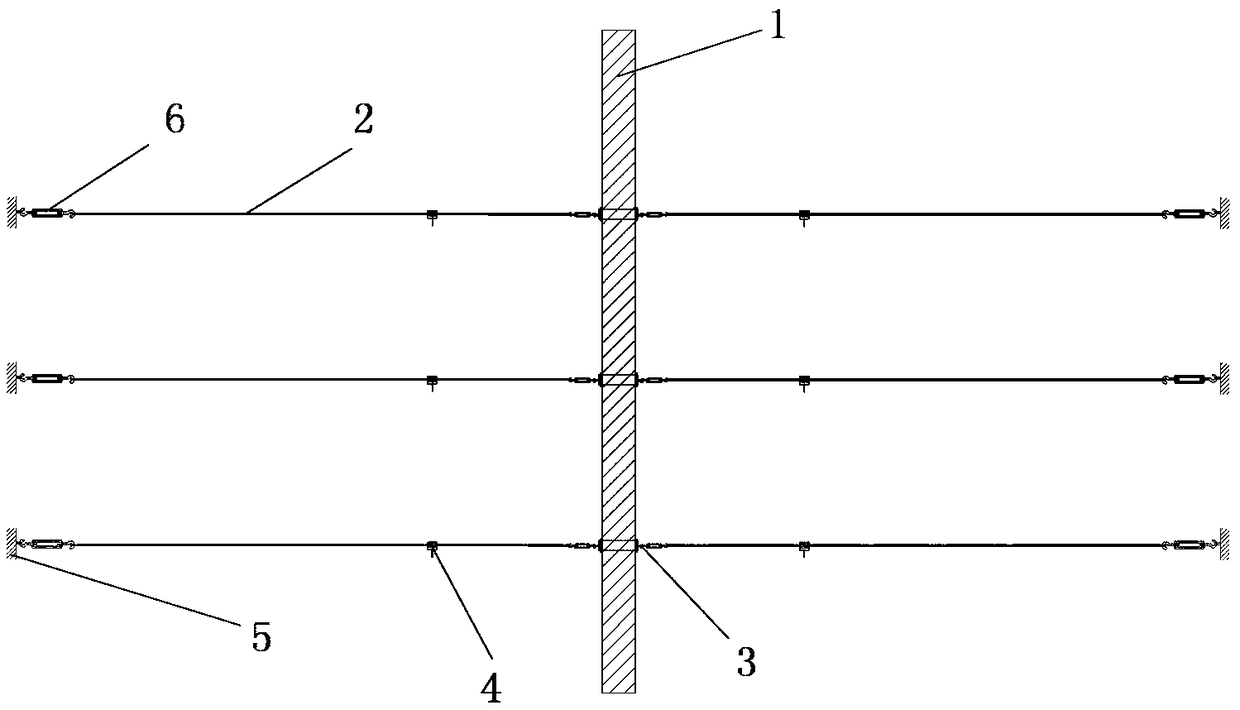

A device and method for preventing out-of-plane instability with force measuring function

An out-of-plane, force-measuring technology, applied in measurement devices, tension measurement, instruments, etc., can solve the problems of increasing friction between the test piece and the device, instability of the test piece plane, influence, etc. Function, device simple and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] S1: Preliminary preparation.

[0030] According to the construction drawings, prepare and process the equipment and appliances, cut six (or eight, even-numbered) flexible steel strands of the same length in advance, and process custom-made restraint belts according to the shape of the specimen (this step should be restrained according to the actual specimen) The shape of the end can be customized), and various types of bolts are prepared;

[0031] S2: Module installation.

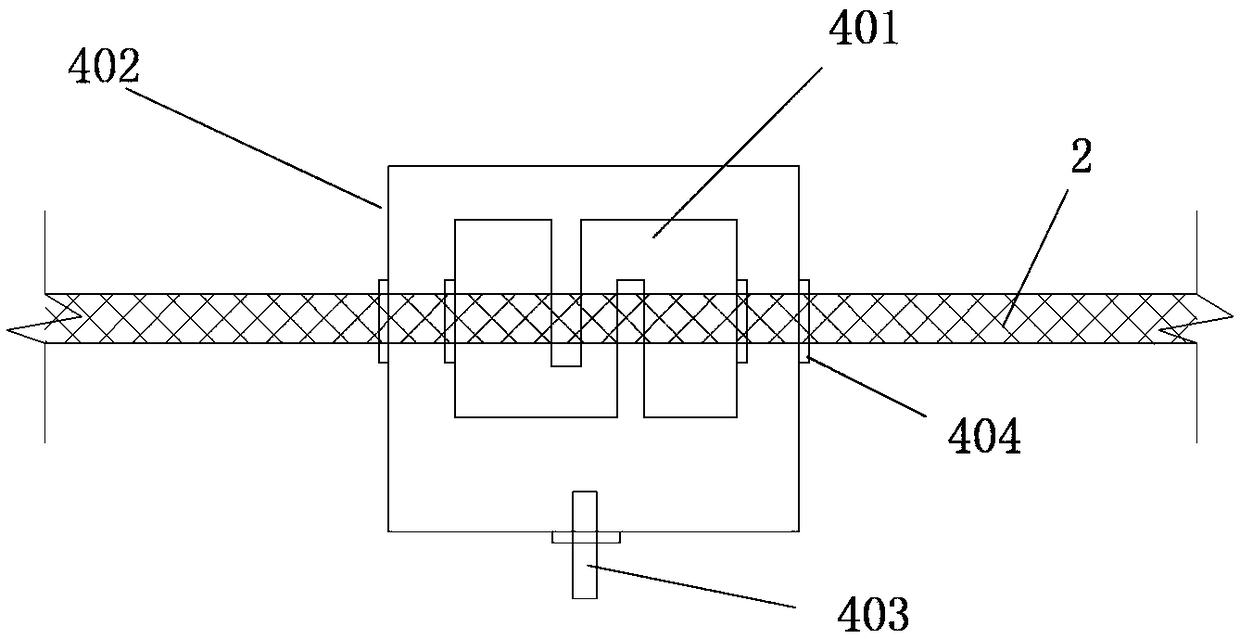

[0032] S2.1, the installation of the force measuring module (4). Place the load cell (401) in the protective case (402), fix it on the flexible steel cable (2) with the connecting bolt (404), and transmit each value measured by the load cell (401) through the signal output line (403). The rope force is transmitted to the external computer equipment, and the pre-testing of the force measuring device is carried out to check whether the installation is correct;

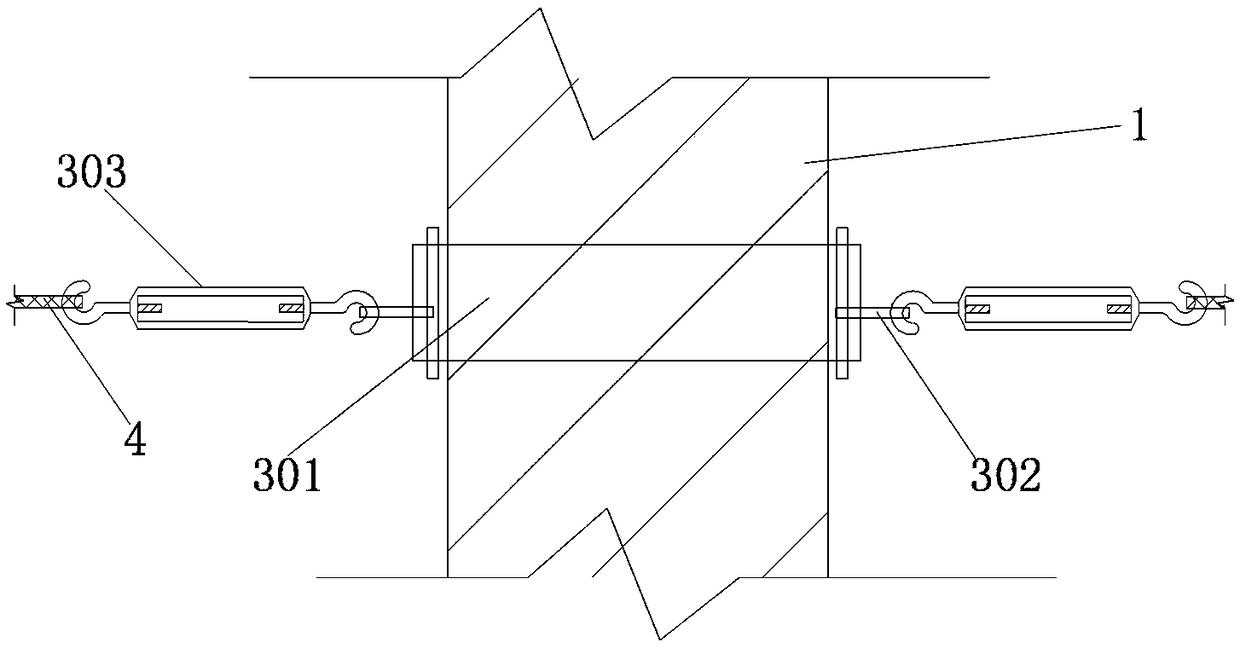

[0033] S2.2. Installation of the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com