Composite floor with steel bar trusses, profiled steel plate and regenerated concrete, and manufacturing method for composite floor

A technology of recycled concrete and profiled steel plates, which can be used in floors, building components, buildings, etc., and can solve problems such as large loads and shear damage of oblique sections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

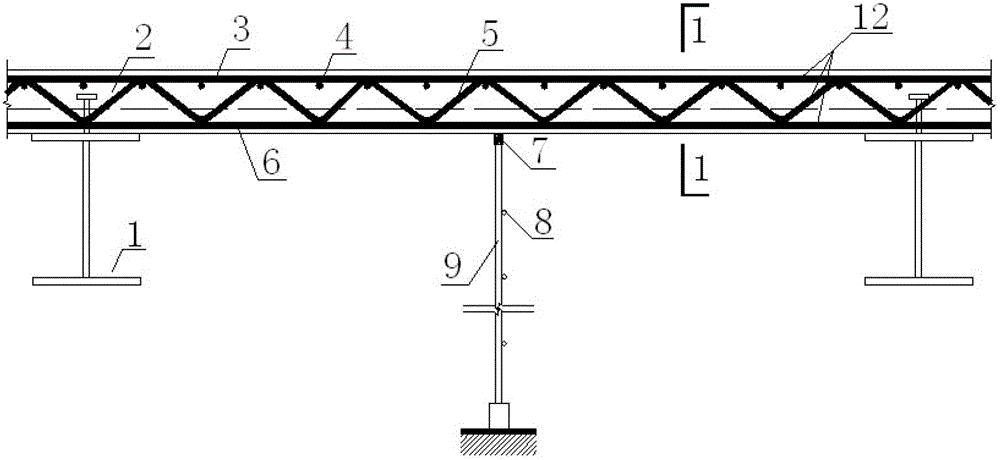

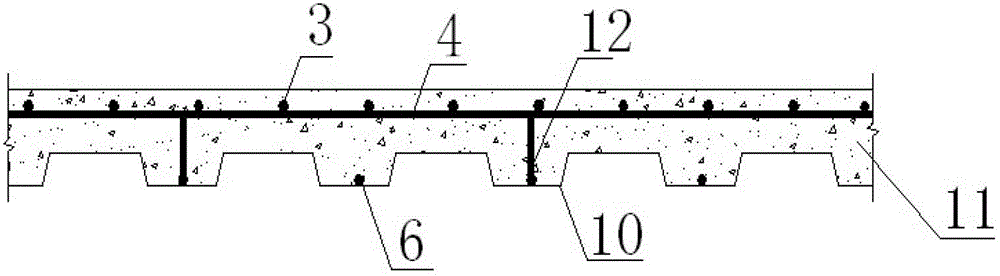

[0025] Such as Figure 1-2 As shown, a kind of steel bar truss-profiled steel plate-recycled concrete composite floor of the present invention mainly consists of profiled steel plate 10, recycled concrete 11 poured on the profiled steel plate 10, oblique lattice type steel bar truss 12 and Composed of transversely distributed ribs 4; profiled steel plate 10 is laid on the steel beam 1 of the main steel structure, the bottom of the profiled steel plate 10 is fixedly connected to the steel beam 1, and each wave groove or compartment of the profiled steel plate 10 is placed with an oblique lattice The steel bar truss 12 of the structural type, the steel bar truss 12 of the oblique lattice type is welded and combined by the serpentine steel bar 5, the tension bar 6 at the bottom of the slab, and the upper longitudinal steel bar 3, and the horizontal distribution bars 4 on the upper part of the concrete slab are erected on the oblique lattice type Steel bar trusses 12 and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com