Novel water open caisson construction technology

A construction technology and caisson technology, applied in caissons, infrastructure engineering, construction, etc., can solve problems such as complicated technology, difficult correction, and large installation deviation, so as to achieve simple and easy operation technology, reduce construction period, and reduce installation The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

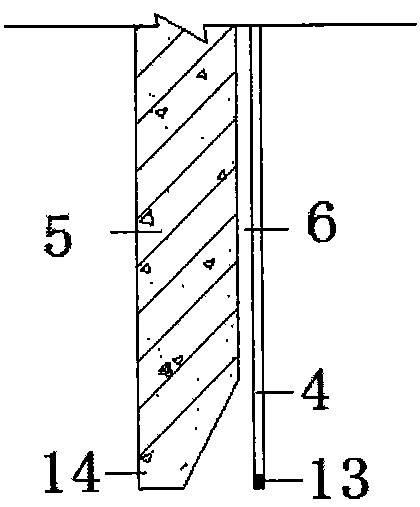

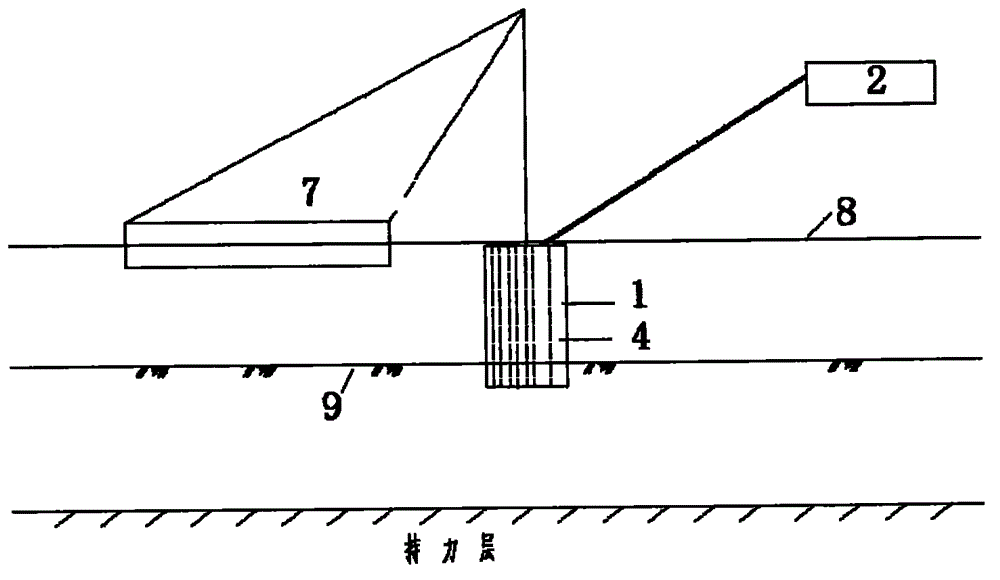

[0019] The caisson 1 is prefabricated as a whole in the onshore prefabrication site. During the prefabrication, steel members should be embedded in the inner wall 6 of the caisson according to the design and layout requirements of the vertical compressed air pipe 4 to fix the vertical compressed air pipe 4, and the end of the vertical compressed air pipe should be installed High pressure air nozzle 13. A bevel 14 will be left at the bottom of the caisson 1 to reduce sinking resistance.

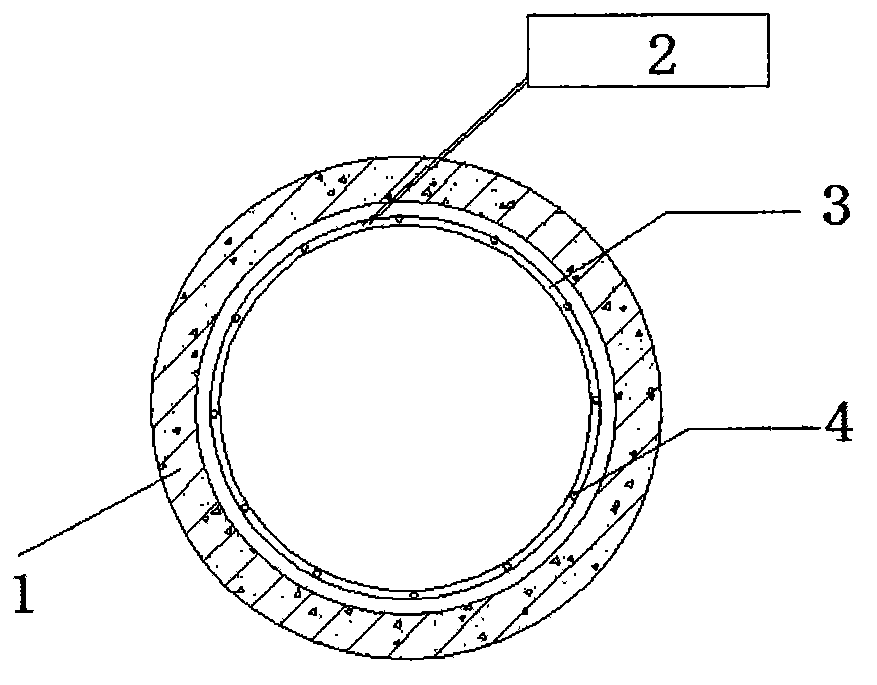

[0020] Fix the vertical compressed air pipe 4, and connect the vertical compressed air pipe 4 with the compressed air parallel pipe 3. The diameter of the vertical compressed air pipe 4 is generally Steel pipes shall be able to withstand high pressure air pressure. The vertical layout spacing of the vertical compressed air pipes 4 is determined according to the soil conditions in the construction area and the capacity of the air compressor 2, generally not exceeding 2 meters. The pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com