Fabricated open caisson structure and construction method thereof

A prefabricated caisson technology, applied in infrastructure engineering, caissons, buildings, etc., can solve problems affecting the construction of caisson structures, reducing the use of underground space, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

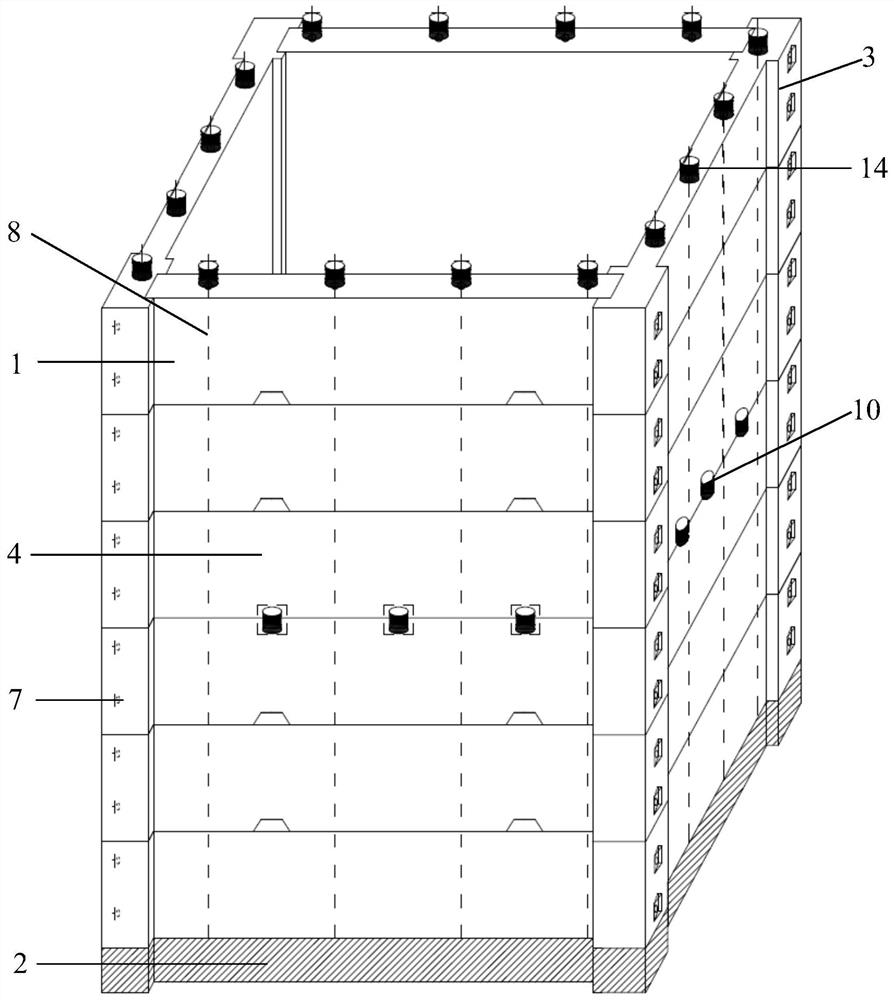

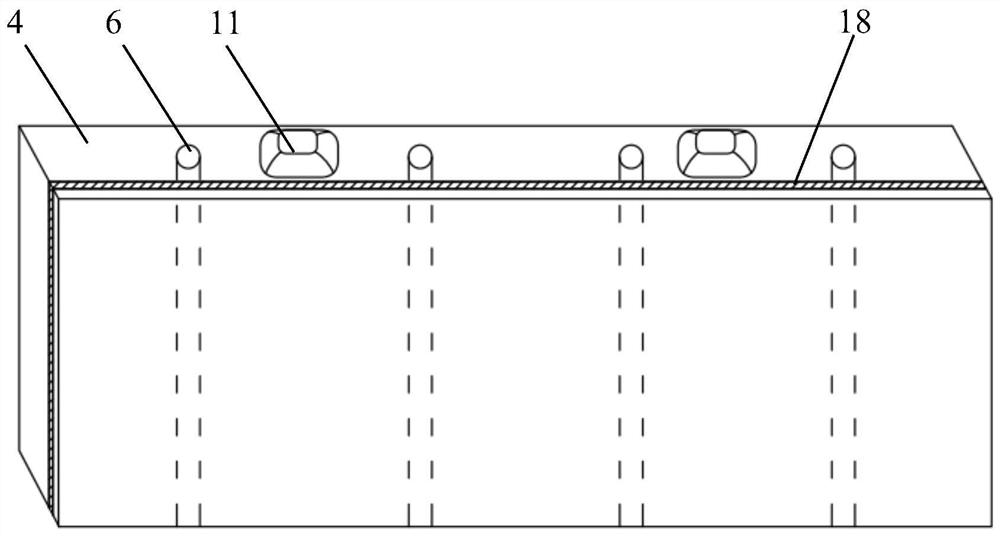

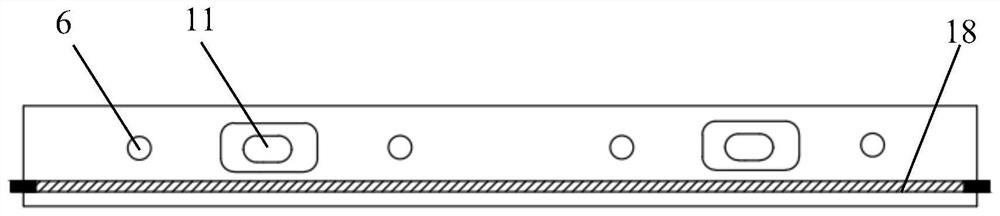

[0042] like Figure 1~9 As shown, an assembled caisson structure, the caisson structure is composed of a shaft wall structure (1) and a floor structure (2), and it is characterized in that the shaft wall structure (1) is composed of a multi-section ring structure (3) each segment of the annular structure (3) is composed of a plurality of prefabricated well slice structures (4) connected end to end; the prefabricated well slice structure (4) is internally provided with horizontal reserved channels (5) and longitudinal reserved channels (6); the transverse connecting member (7) can be accommodated in the transverse reserved channel (5), and the transverse connecting member (7) can connect a plurality of prefabricated well slice structures (4) in a single ring structure (3) Tighten and lock; the longitudinal connecting member (8) can be accommodate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com