Construction method for cast-in-situ caisson formwork-supporting system

A construction method and caisson technology, applied in caissons, infrastructure engineering, construction, etc., can solve the problems of poor verticality, floating formwork, large number of steel pipes, etc., and achieve the effect of reducing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In this embodiment, the steel structure welding process, bolt connection construction process, formwork setting process, and concrete pouring construction process will not be repeated in this implementation, and the embodiments of the structure related to the present invention will be focused on.

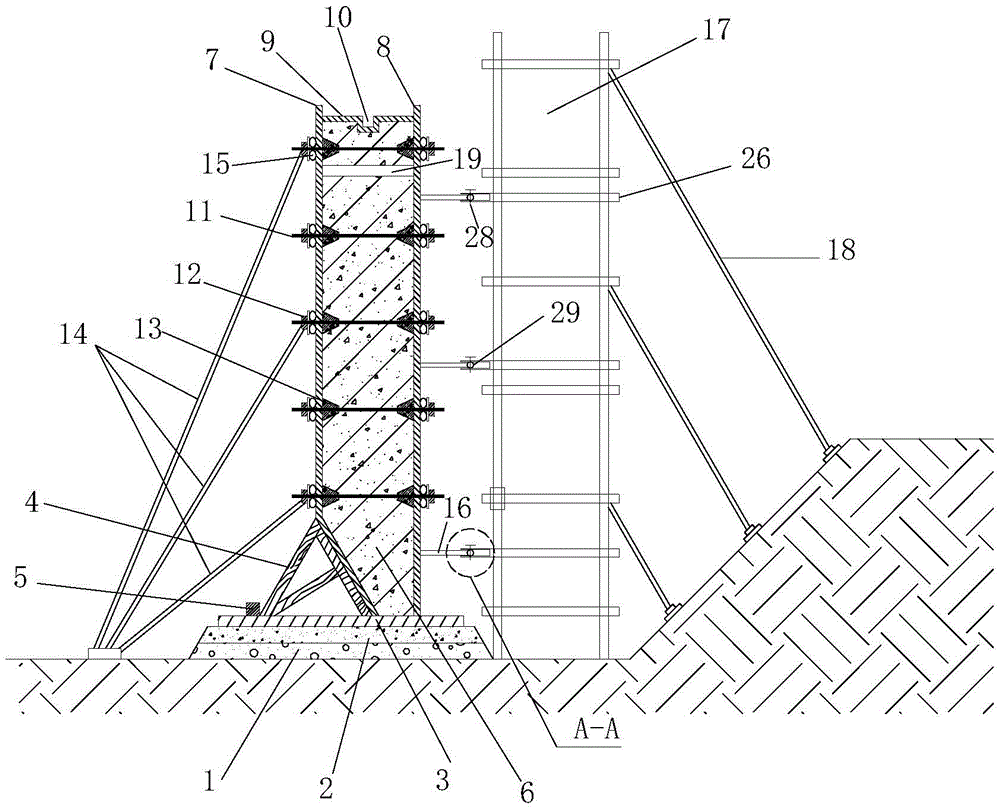

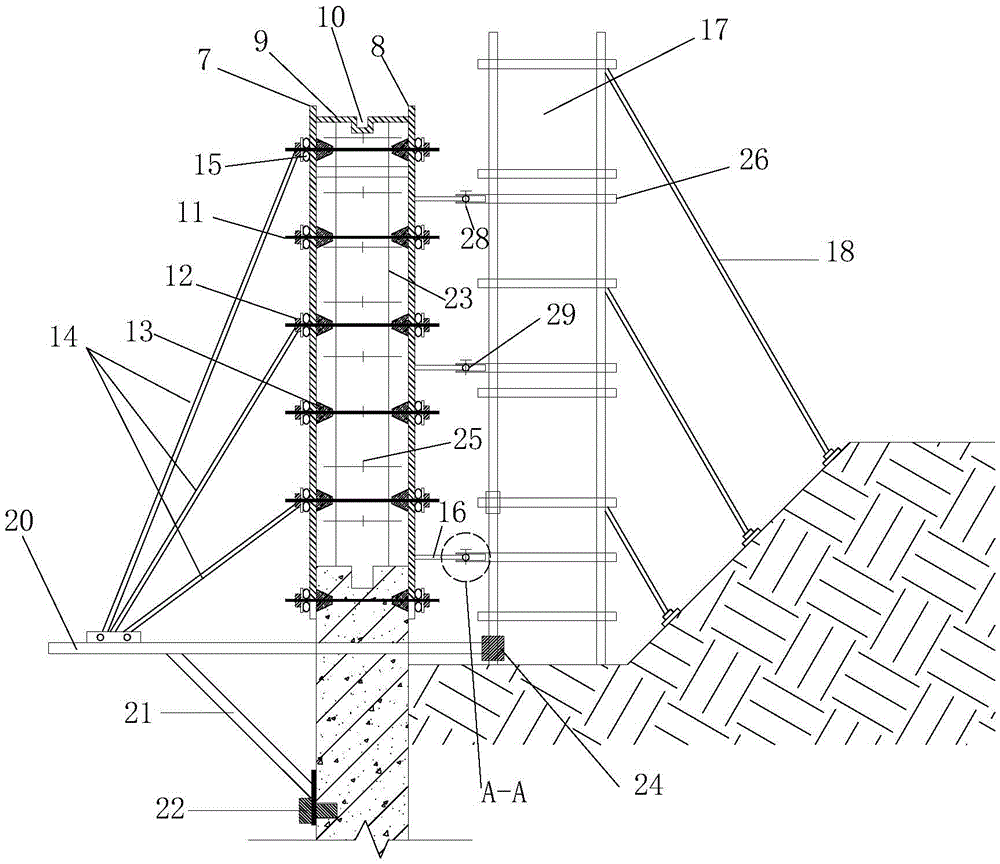

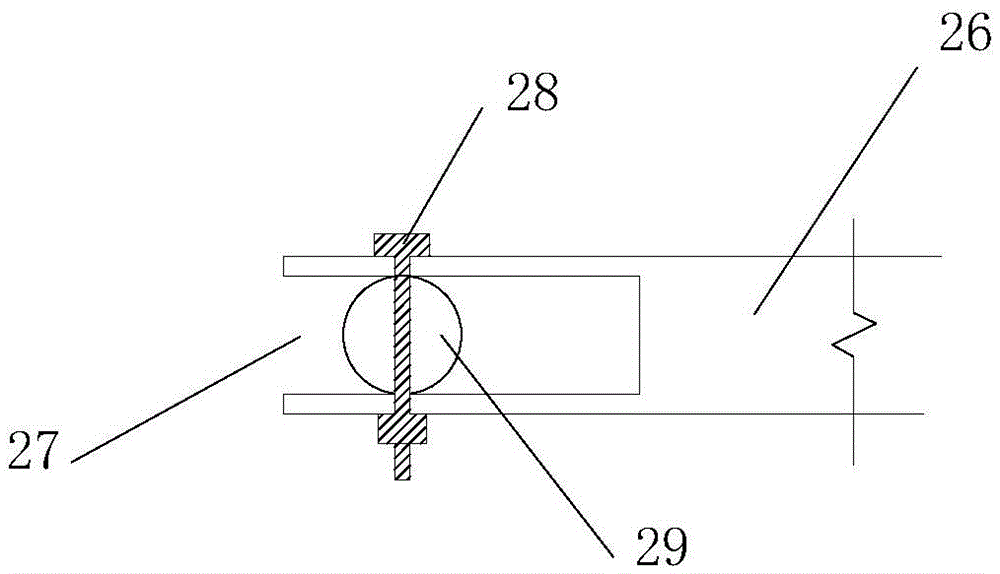

[0027] figure 1 It is a structural schematic diagram of the first section of the caisson formwork system of the present invention. refer to figure 1 As shown, the cast-in-place caisson formwork support system of the present invention mainly includes: pad frame 4, inner formwork 7, outer formwork 8, screw rod 11, oblique support 14, transverse support 16, wall-penetrating steel pipe 20, movable rod 29, embedded Pieces 22, double-row scaffolding 17.

[0028] refer to figure 1 As shown, before the construction of the caisson formwork, a layer of sand and gravel cushion 1 is first laid on the bottom of the caisson, and a layer of plain concrete cushion 2 is poured on the sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com