Bridge composite foundation consisting of open caisson and pile and construction method

A composite foundation and construction method technology, which is applied in the direction of foundation structure engineering, caissons, buildings, etc., can solve the problems of large post-construction settlement, complex mechanical mechanism, weak applicability of soil foundation, etc., and achieve increased compaction and consolidation , Pile foundation construction is convenient, and the effect of reducing post-construction settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

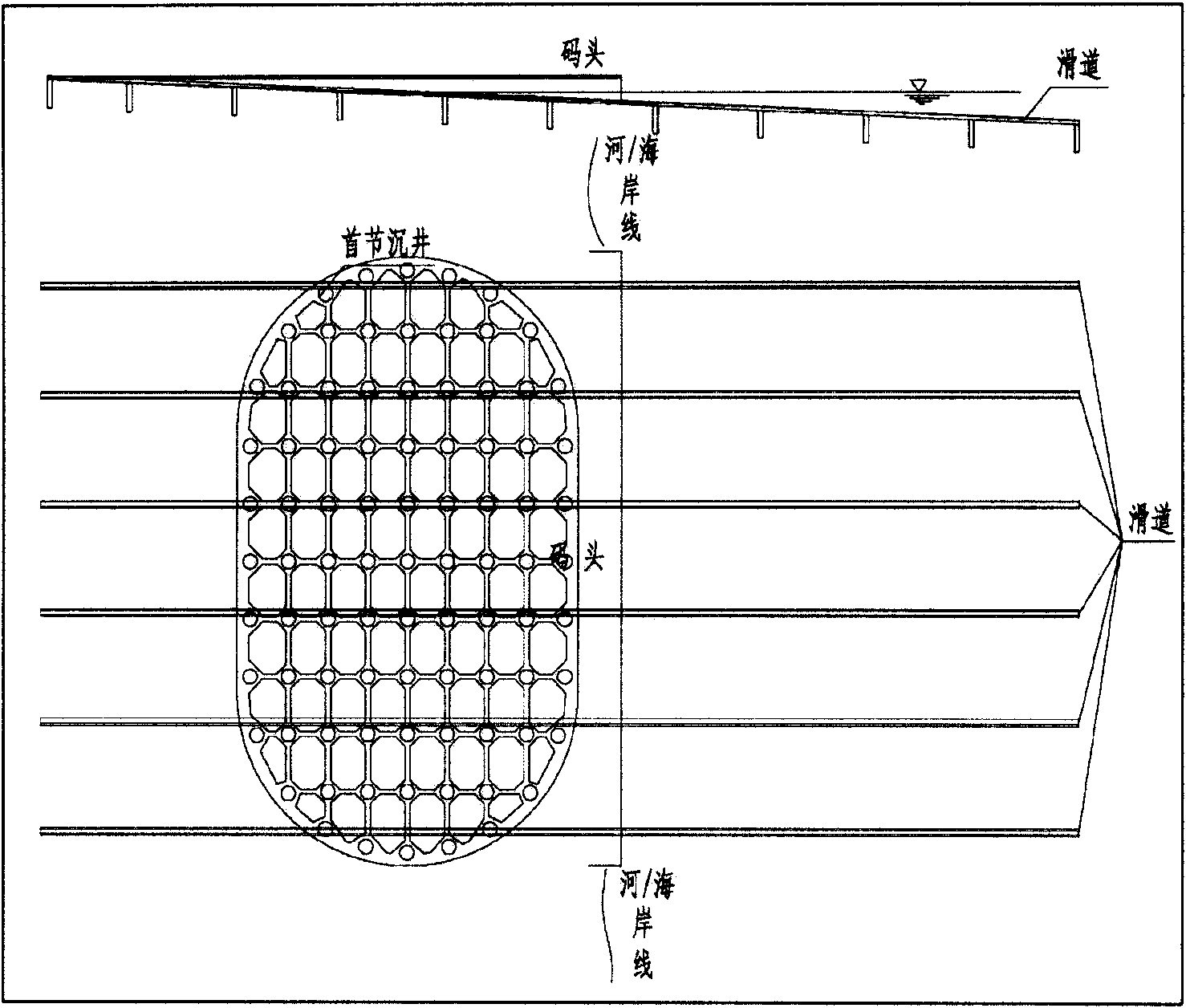

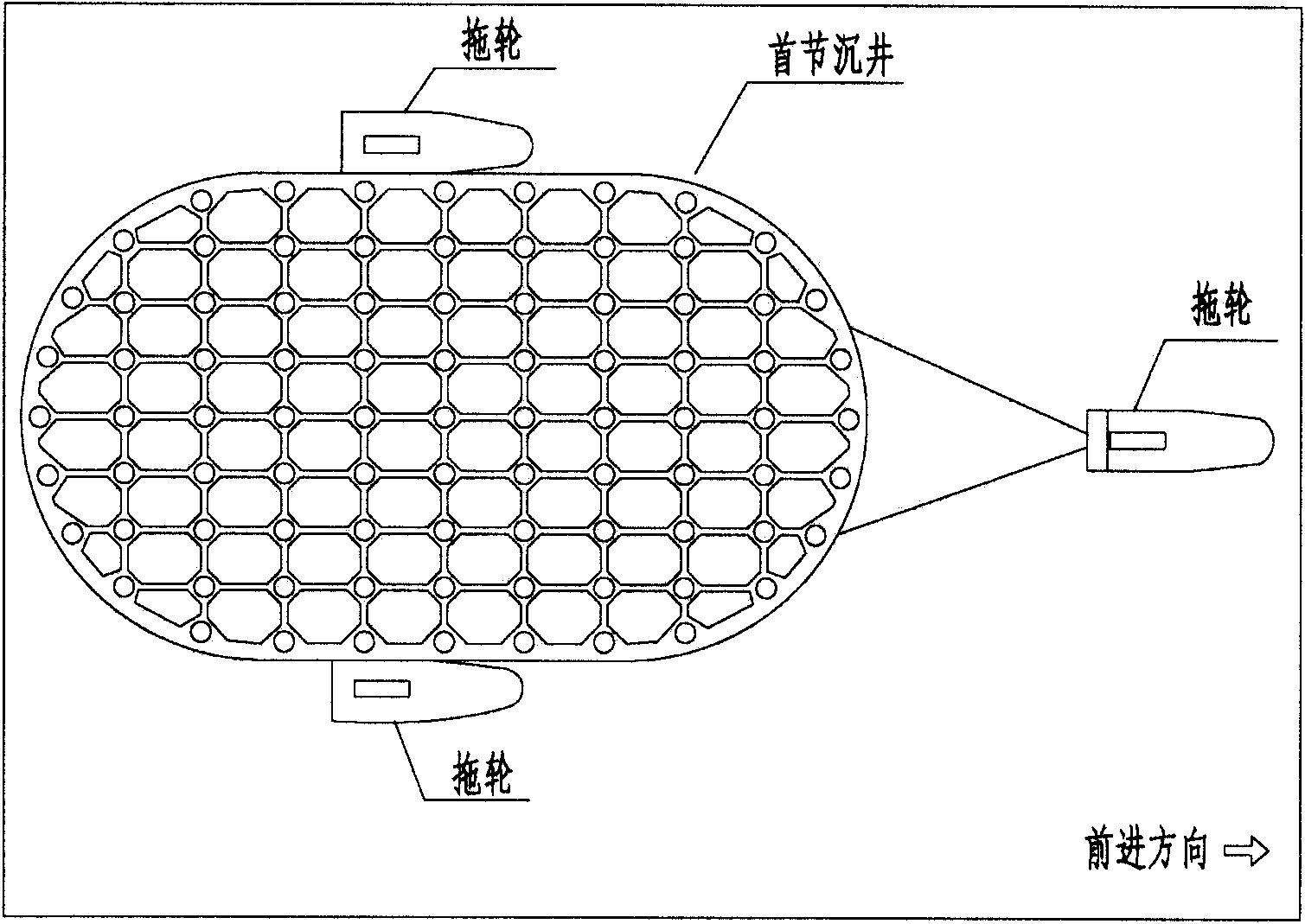

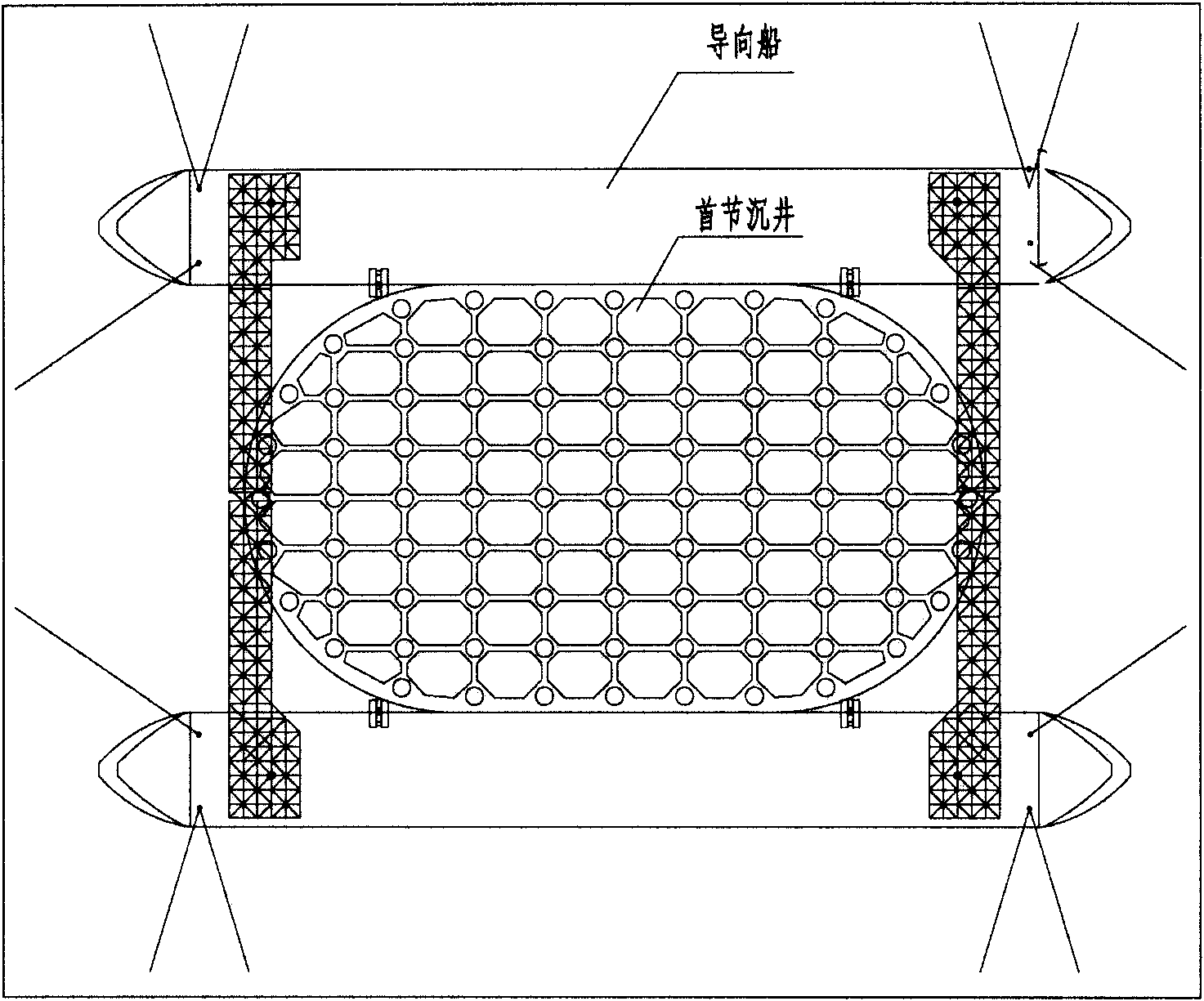

[0062] See figure 1 , 2 , which is a composite foundation structure schematic diagram of "a bridge composite foundation composed of caissons and piles and construction method" of the present invention, in which there are: roof 1, shaft wall 2, partition wall 3, bottom sealing concrete 4, well hole 5, Piling reserved hole 6, pile 7, riprap 8, sea (or river, river) bed 9.

[0063] Among them, the partition wall 3 is a vertical and horizontal wall structure; a reserved hole 6 for sinking piles is set at the junction of the vertical and horizontal partition walls 3 of the caisson, and the steel pipe piles or concrete driven piles 7 are all sunk through the reserved holes 6 for sinking piles. , after the pile foundation construction is in place, concrete is poured between the pile 7 and the wall of the hole 6 reserved for sinking the pile, so as to realize the firm connection between the caisson and the pile 7.

[0064] The "composite bridge foundation composed of caissons and pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com