Exhaust pipe connection structure and exhaust pipe connection method

A technology of connection structure and connection method, which is applied in the direction of non-detachable pipe connection, pipe/pipe joint/pipe fitting, exhaust device, etc., can solve the problems of time-consuming processing and non-optimal welding, and achieve the effect of improving shape accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, the best mode for carrying out the present invention will be described in more detail based on the accompanying drawings.

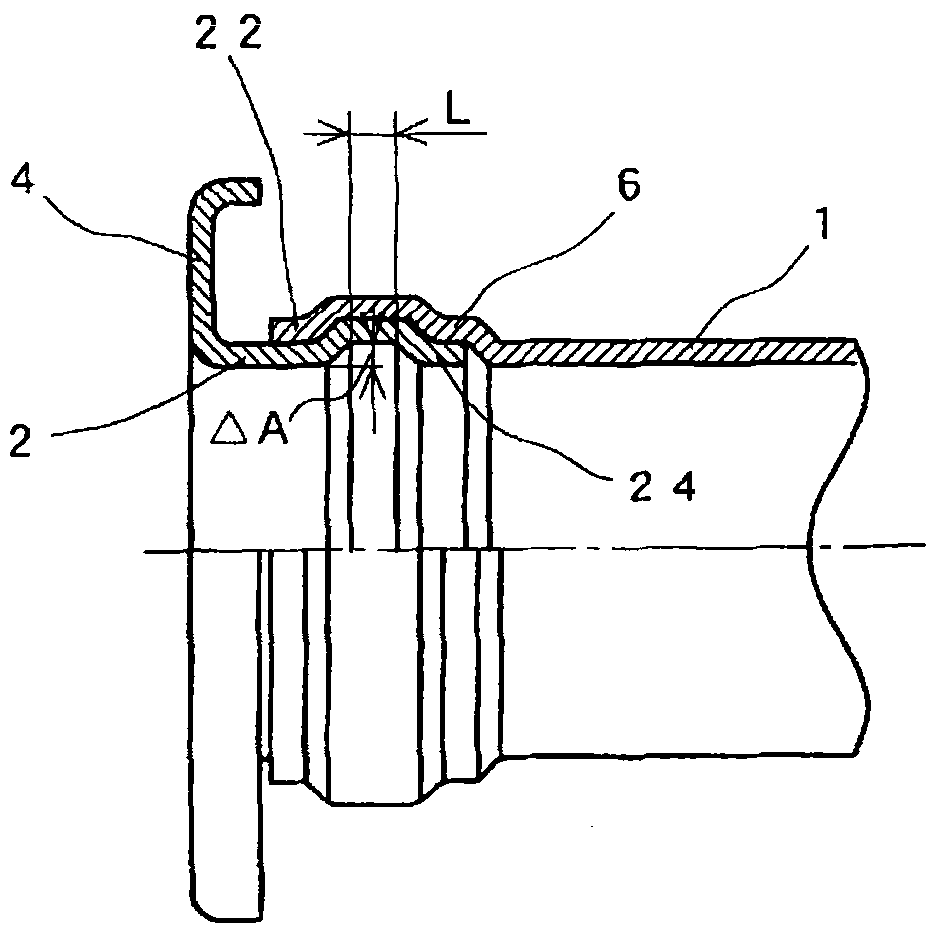

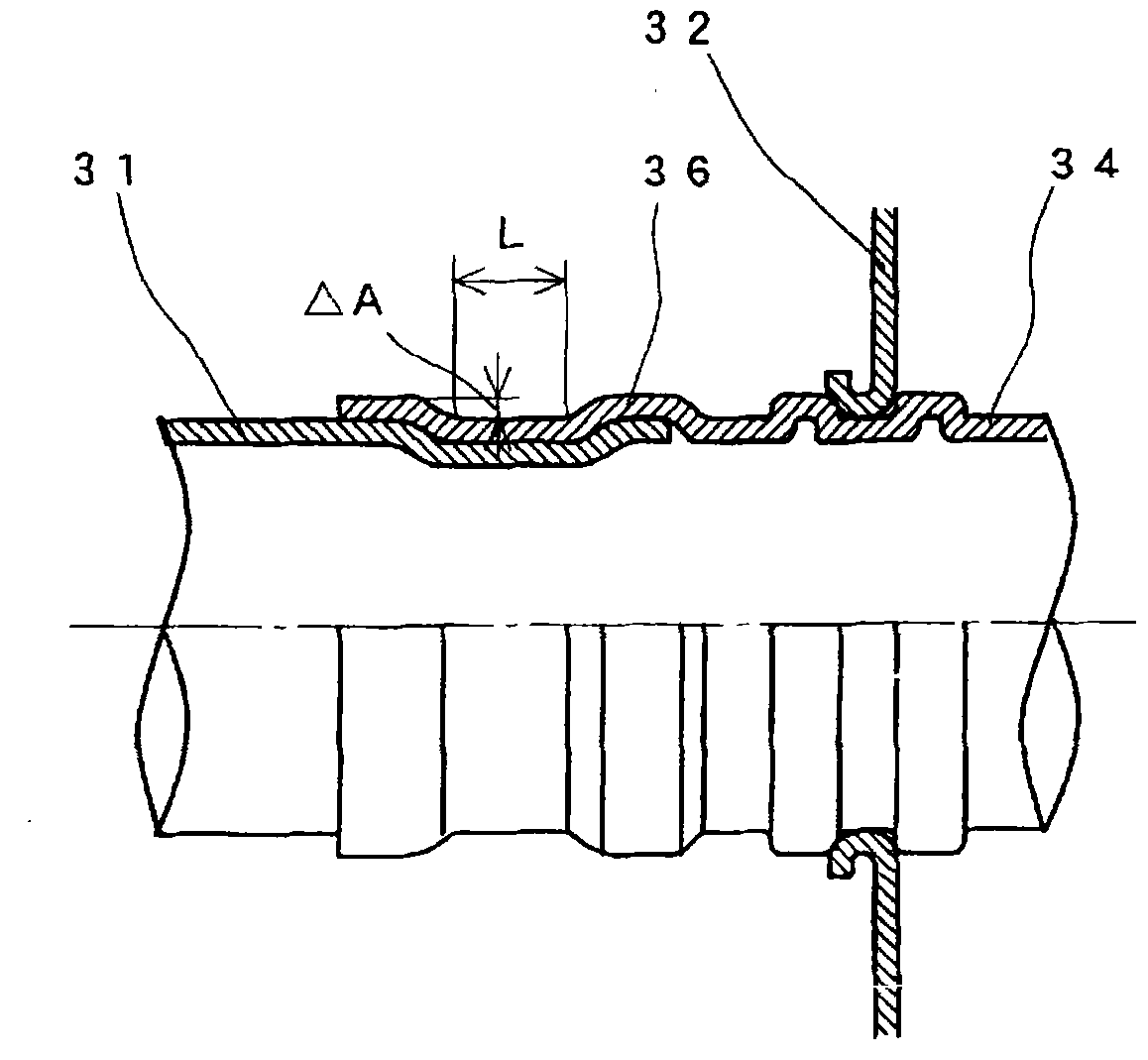

[0039] Such as figure 1 As shown, numeral 1 denotes an exhaust pipe, and a connecting pipe 2 is inserted into the exhaust pipe 1 for mutual connection. The flange 4 is integrally formed in advance on one end side of the connecting pipe 2 by, for example, press working. Also, an enlarged diameter portion 6 is preliminarily formed at one end of the exhaust pipe 1 so that the connection pipe 2 can be inserted thereinto. The outer periphery of the connecting pipe 2 is inserted into the inner periphery of the enlarged diameter portion 6, and the portion where the enlarged diameter portion 6 and the connecting pipe 2 overlap each other is radially molded for mutual connection.

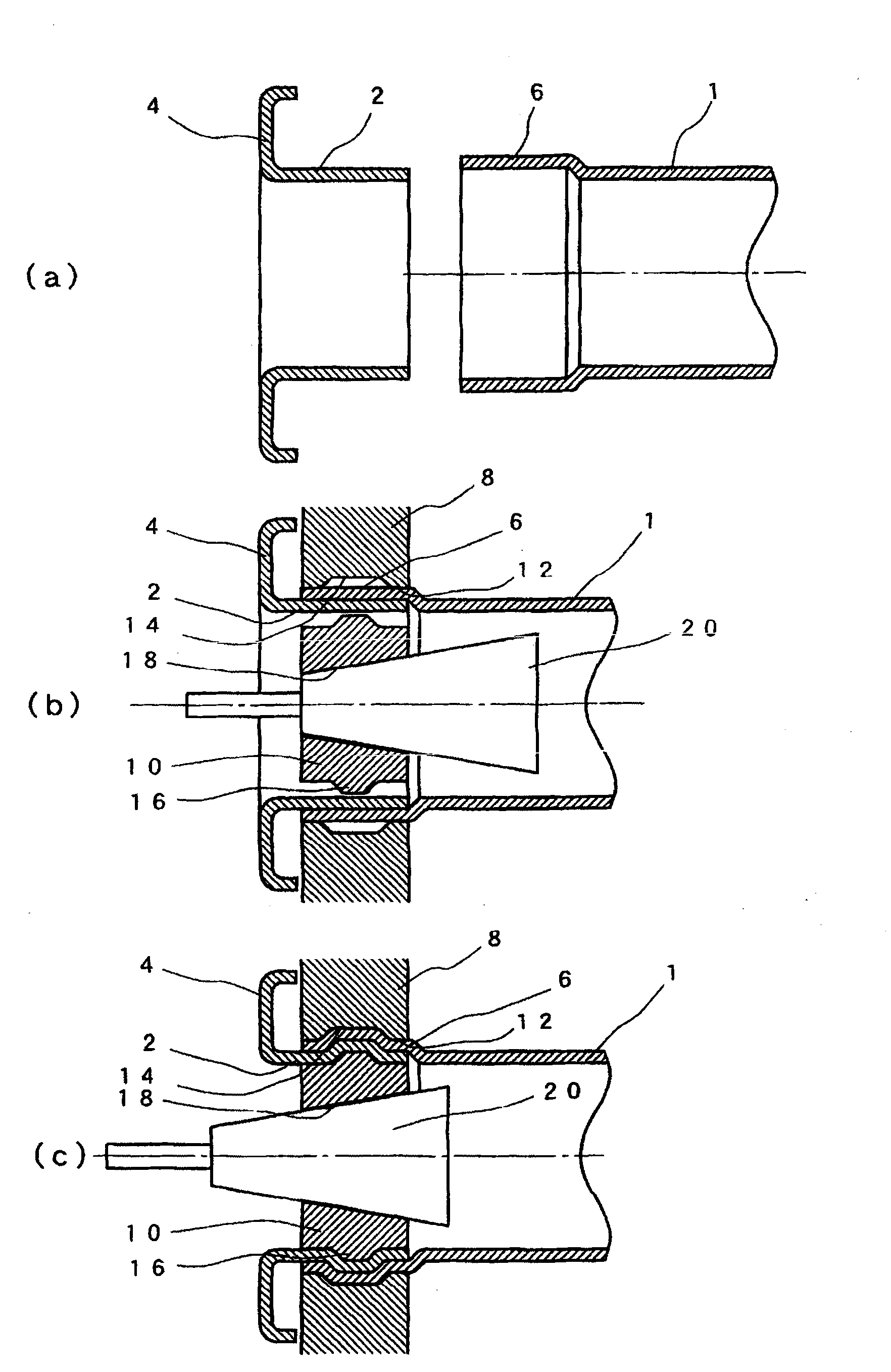

[0040] Next, refer to figure 2 Connection methods are described in process order. Such as figure 2 As shown in (a), the enlarged diameter portion 6 is formed in advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com