Beam string structure

A technology of string beams and steel beams, applied in the field of building structures, can solve problems such as structural safety hazards, cable relaxation, chemical instability, etc., and achieve the effect of eliminating safety hazards and avoiding cable relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

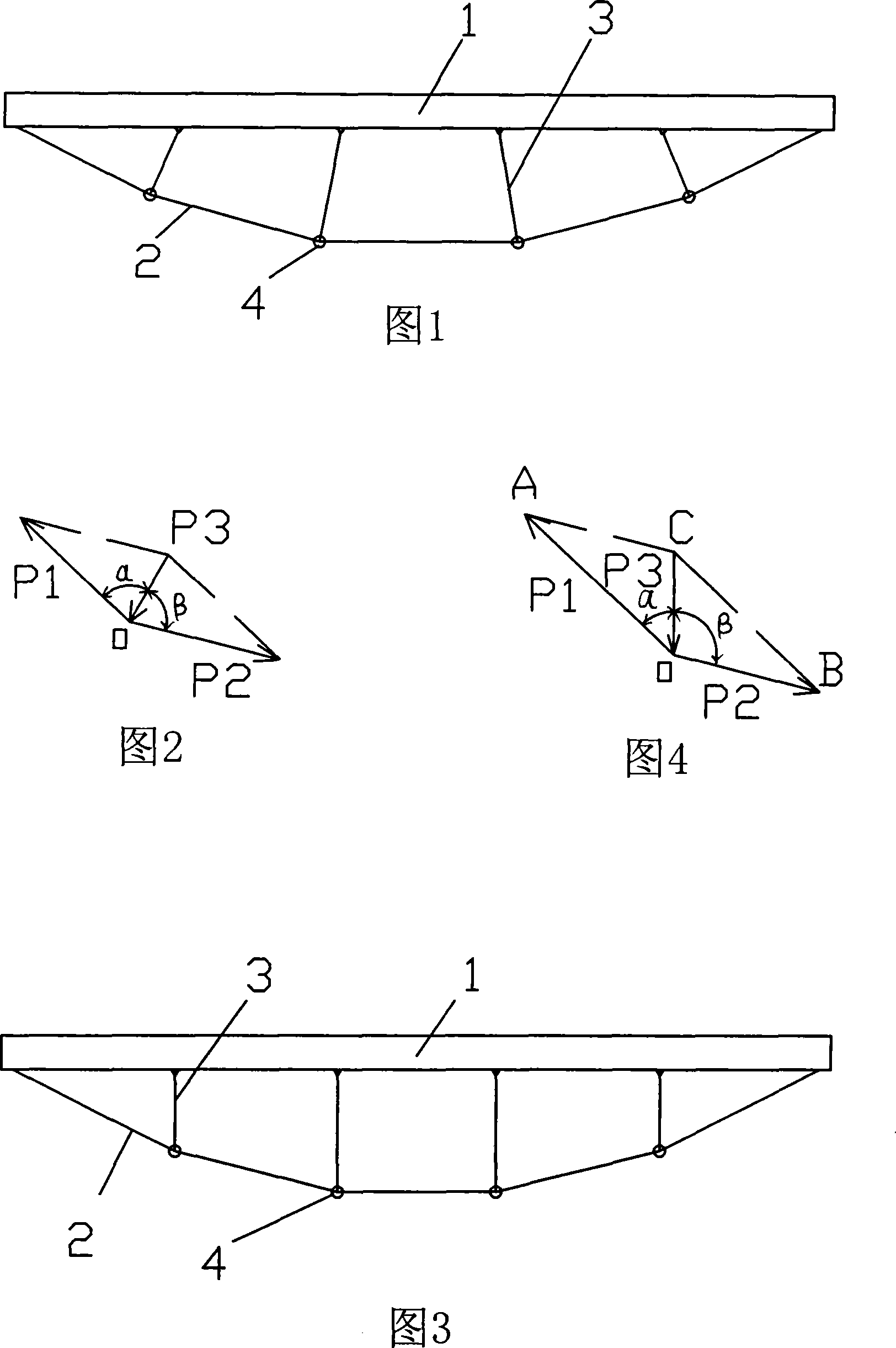

[0014] As shown in Figure 1, a string string beam of the present invention comprises: a rigid beam 1, a stay cable 2 and several struts 3, the upper ends of the struts 3 are hinged to the rigid beam 1, and the lower ends of the struts 3 pass through the cable clamps 4 It is fixedly connected with the cable 2, and the two ends of the tensioned cable 2 are respectively fixedly connected with the two ends of the rigid beam 1. The cable 2 forms an axisymmetric fold line, and two adjacent fold lines form a fold line angle. Each turning point is located on the same parabola, and the characteristic is that each strut 3 is respectively located on the bisector of the angle of the broken line where it is located.

[0015] As shown in Figure 2, the connection point between any strut and the connected cable is taken as the research object of static force balance. , according to the balanced quadrilateral law to form a balanced force system, since the angle α is equal to the angle β, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com