Slack preventing device for wire rod wound around spool, and slack preventing method therefore

A wire and spool technology is applied in the field of preventing the slack of the wire wound on the spool, which can solve the problems of the slack of the wire 4, the difficulty in increasing the winding speed, and the difficulty in quickly exporting the wire, and achieve the effect of preventing slack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

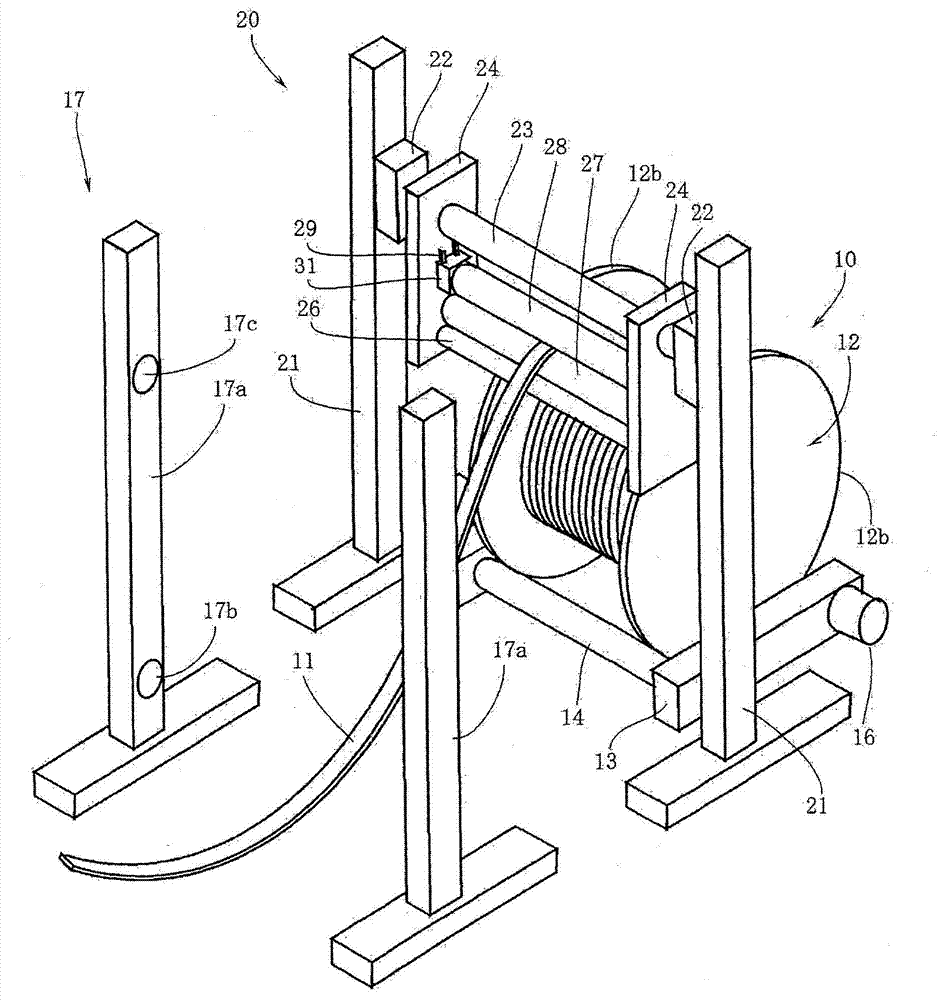

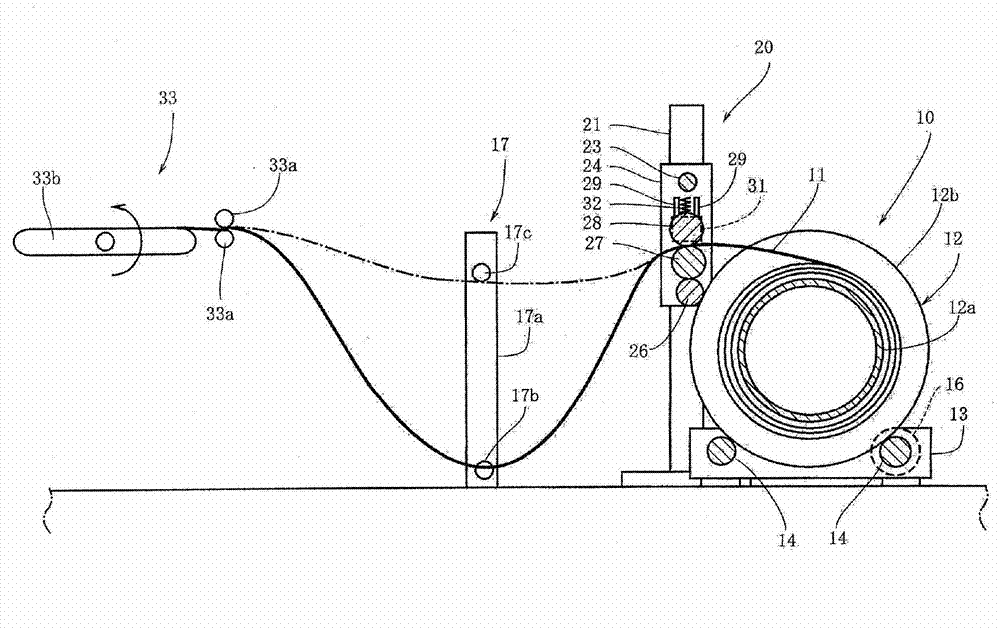

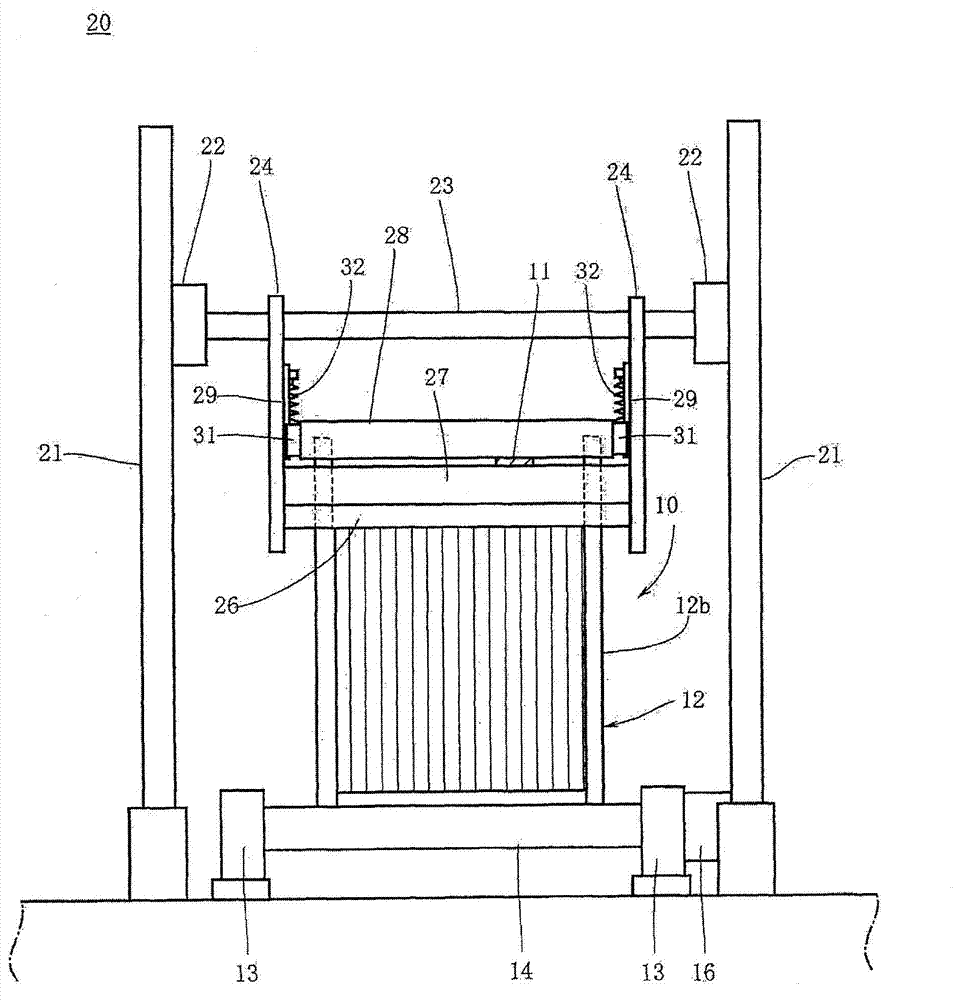

[0022] Next, the form for implementing this invention is demonstrated in detail based on drawing.

[0023] Figure 1~Figure 3 The device 20 for preventing wire slack of the present invention is shown in FIG. The wire slack prevention device 20 is provided together with the wire lead-out machine 10 that pulls the wire 11 out by rotating the bobbin 12 around which the wire 11 is wound. The wire 11 in this embodiment shows the case where a so-called flat wire whose cross-section is rectangular is used, but the wire 11 may be a so-called square wire whose cross-section is square, or may be a circular cross-section. The so-called circular line. In addition, the wire 11 may be, for example, a long strip like a film. The bobbin 12 for winding such a wire 11 has a cylindrical main body portion 12a ( figure 2 and Figure 4 ), the above-mentioned wire 11 is actually wound around the outer periphery of the main body portion 12a; the disc-shaped flange portion 12b is coaxially forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com