Submersible buoy pulley mooring system

A mooring system and pulley technology, applied in the field of mooring systems, can solve problems such as sudden increase in rope tension and offset of tension on both sides of the floating body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0157] Further description will be made below in conjunction with the accompanying drawings.

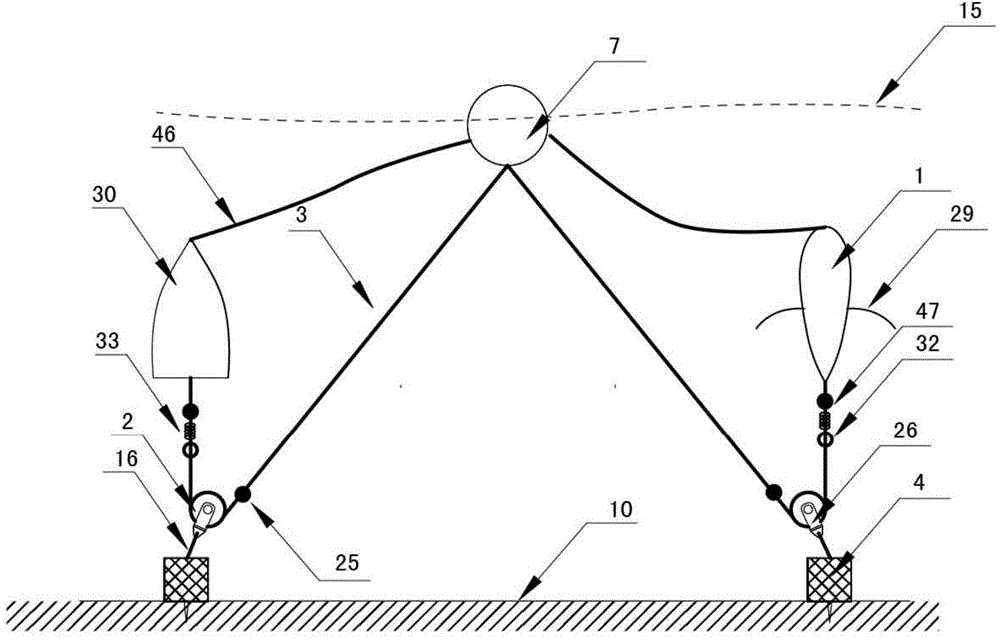

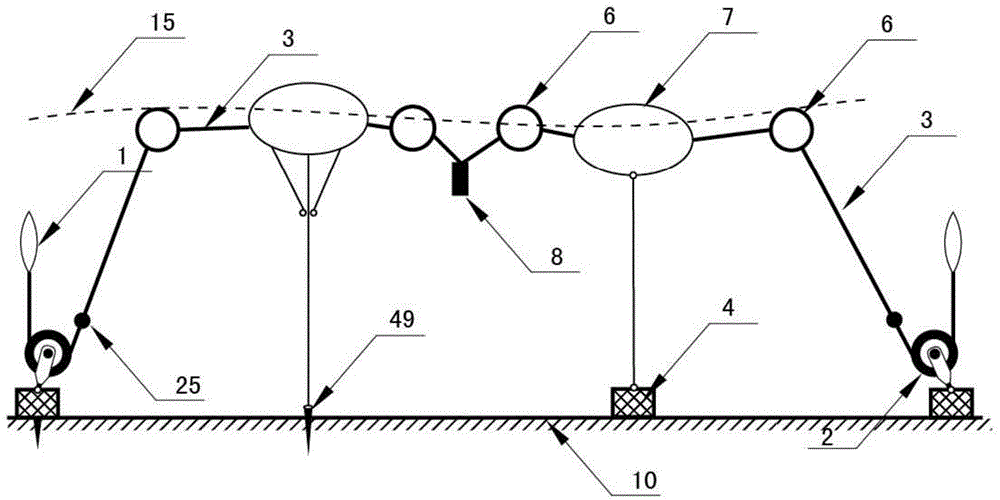

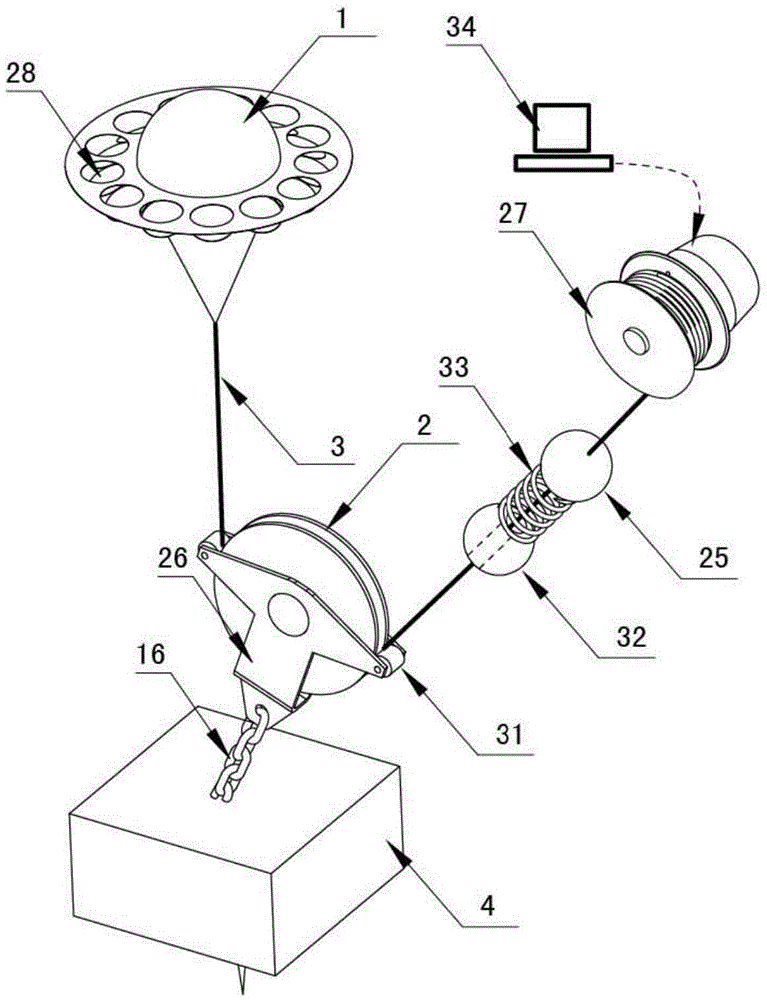

[0158] figure 1 It is a mooring principle diagram of a single floating body submersible buoy pulley: including submersible buoy 1, pulley 2, anchor base 4, rope 3, one end of a rope 3 is tied to the submersible buoy 1 or 30 whose specific gravity is smaller than water, and the other end bypasses the fixed pulley 2. After being tied to the floating body 7 to be moored, there is a knot 25 between the fixed pulley 2 and the floating body 7 to be moored close to the fixed pulley 2. The outline of the knot 25 is larger than the gap between the pulley frame 26 and the pulley 2 and cannot Through, the knot 25 here is a protruding point on the rope, which can be a solid on the rope, or a knot made by the rope itself; Hinge 42, see image 3 connected with the anchor base 4); the above forms a submersible mark pulley anchoring unit; the ropes of multiple groups of peripheral submersible mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com