Connection device and connection method for preventing steel structure column foot from being tensioned

A connecting device and steel structure technology, which is applied in basic structure engineering, building construction, construction, etc., can solve the problems of weak safety redundancy of column feet, increase of column foot area, and hidden safety hazards in steel structure systems, etc., to achieve The effect of improving safety redundancy, improving connection stiffness, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

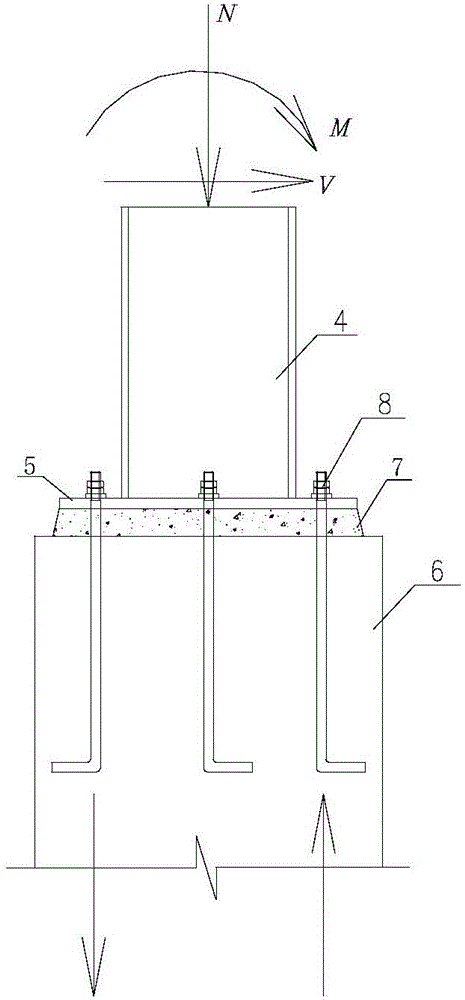

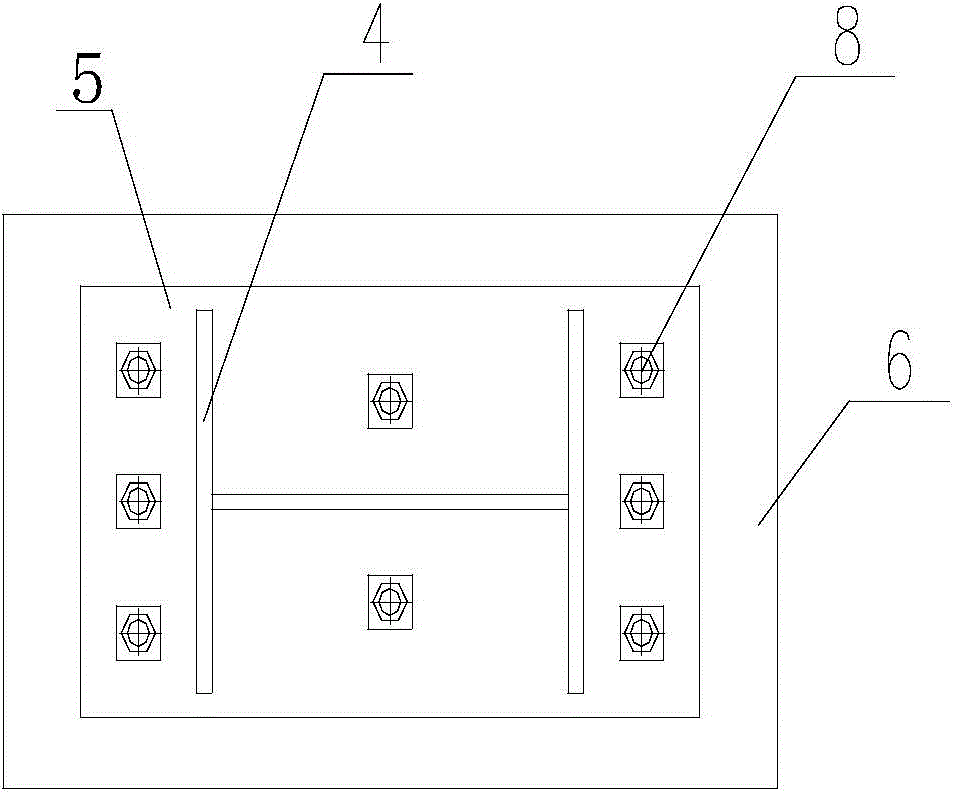

[0040] The steel structure column foot of the present invention is a tension-free connection member, such as Figure 4 , 5 As shown in, 6, it is composed of prestressed tie rod pair 1, combined gusset plate 2 and embedded casing 3. The prestressed tie rod pair 1 is formed by connecting the upper and lower steel tie rods 11 with threads on the two ends to be integrated by the positive and negative buckle sleeves 12; the lower steel tie rod 11 of the prestressed tie rod pair 1 passes through and is embedded in the concrete foundation. 6 The embedded casing 3 on the tension side is connected with the nut 13; the upper steel tie rod 11 of the prestressed tie rod pair 1 passes through the hole in the pre-welded composite gusset plate 2 on the tension side of the steel column and the nut 13 Connection; the upper and lower steel tie rods 11 of the prestressed tie rod pair 1 apply prestress to the steel tie rod 11 by rotating the positive and negative buckle sleeve 12.

[0041] Wherein, ...

Embodiment 2

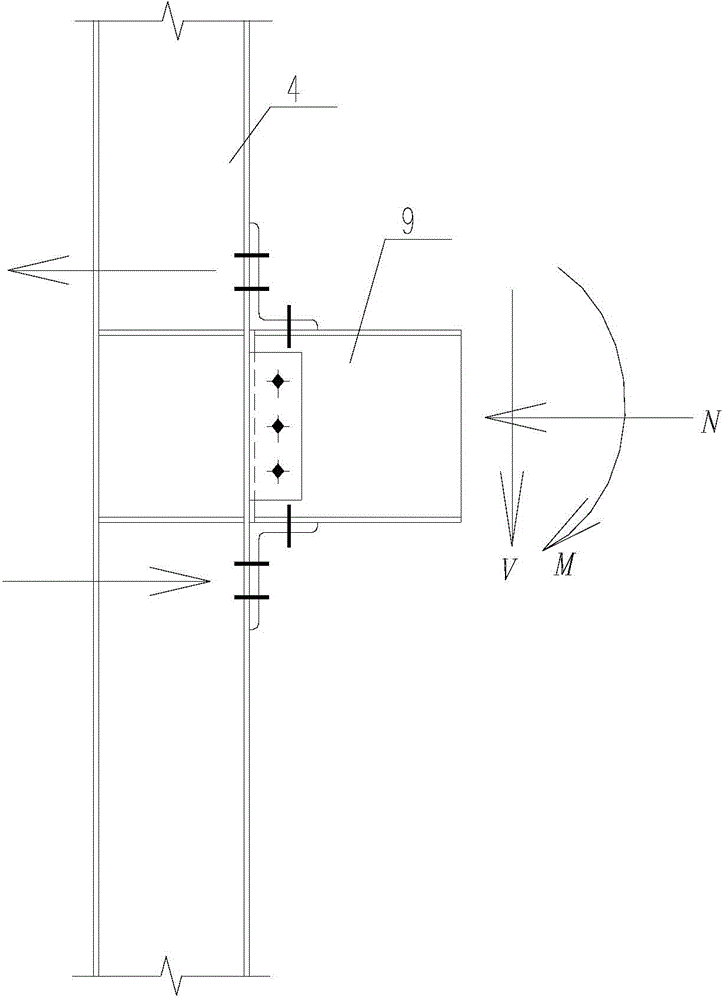

[0054] The tension-free connection member and method of the steel structure column foot of the present invention are applied to beam-column connection.

[0055] Such as Picture 9 , 10 As shown, the tension-free connection member of the column foot of the steel structure of the present invention is applied to the connection of beams and columns, and is composed of a prestressed tie rod pair 1 and a combined gusset plate 2.

[0056] Such as Image 6 As shown, the pre-stressed tie rod pair 1 is formed by connecting two sections of steel tie rods 11 with threads at both ends through positive and negative buckle sleeves 12, and the steel tie rod 11 is made of high-strength round steel.

[0057] The combined gusset plate 2 is composed of three plates, of which the right-angled sides of the two right-angled triangle plates and the rectangular plate are welded together in a "∏" shape.

[0058] The combined gusset plate 2 is pre-welded on the outside of the tension flange of the steel beam 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com