Wood-based composite pipe and preparation method thereof

A composite pipe and wood-based technology, applied in the field of pipelines, can solve the problems of heavy steel or stainless steel pipes, large consumption of mineral resources and energy, non-recyclable products and waste, etc., to achieve good rigidity, low cost, improve the quality of gluing and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

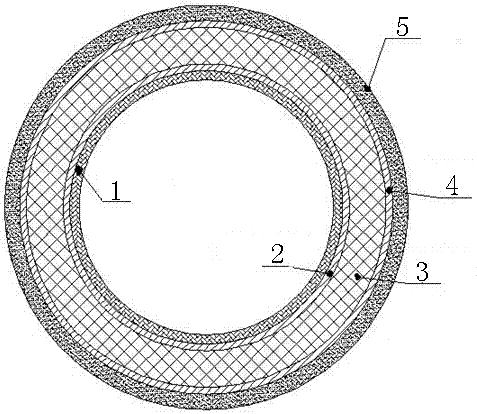

[0026] A method for preparing a wood-based composite pipe, comprising the following steps:

[0027] (1) Preparation of the inner lining layer: the inner lining layer is made of resin and felt fabric or fiber products on the straight pipe mold to form an inner lining layer with anti-seepage and smooth inner wall;

[0028] (2) The treatment of wood-based reinforcement materials is divided into the following three processes:

[0029] 1) Rotate the wood (wood section) into wood veneer;

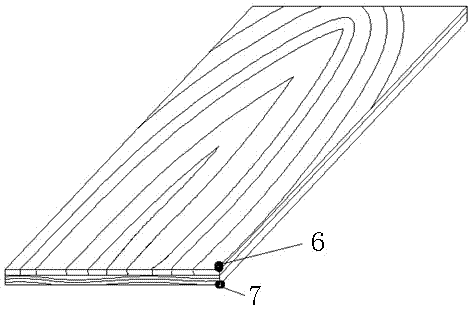

[0030] 2) According to the method of making wooden plywood, the texture of the wooden veneer is criss-crossed, and the water-resistant adhesive is used to glue the wooden plywood with an asymmetric structure;

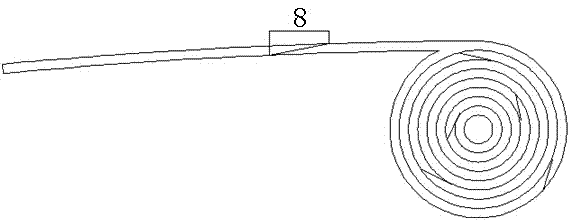

[0031] 3) Saw the wooden plywood into slats of fixed width, and then use a bevel milling machine to mill the end into a bevel, and use the bevel to overlap and glue to lengthen the length required for the winding process, and roll it up for later use;

[0032] (3) Preparation of wood-base...

Embodiment 1

[0041] Taking the production of a wood-based composite pipe with a diameter of 200mm as an example, the specific steps are as follows:

[0042] 1) Treatment of wood-based reinforcement materials:

[0043] a) The wood is peeled and processed, dried to a moisture content of 8% to 10%, and made into 2m (along the fiber direction) × 1m (transverse fiber direction) × 1.0mm (thickness) and 2m (transverse fiber direction) × 1m ( Along the fiber direction) × 1.0mm (thickness) two sizes of wood veneer;

[0044] b) The fiber direction of two types of wood veneers is formed at 90 degrees, and glued with phenolic adhesive to form a two-ply board of 2m×1m×1.8mm (compression rate is about 20%);

[0045] c) Fix the width of the plywood, and cut it into strips with the size of length × width × thickness 2m × 100mm × 1.8mm;

[0046] d) Mill out a 7mm-long slope on each of the two end faces in the length direction of the slat, and glue the front and rear slopes together to form a long coil of...

Embodiment 2

[0055] Taking the production of a composite pipe with a diameter of 300mm as an example, the specific steps are as follows:

[0056] 1) Treatment of wood-based reinforcement materials:

[0057] a) The wood is peeled and processed, dried to a moisture content of 8 to 10%, and made into 2m (in the direction of the fiber) × 1m (in the direction of the fiber) × 1.5mm (thickness) and 2m (in the direction of the fiber) × 1m (in the direction of the fiber) Fiber direction) × 1.2mm wood veneer in 2 specifications and sizes;

[0058] b) Assemble the two kinds of veneer fiber directions at 90 degrees, in which the wood fibers of the 1.2mm veneer are arranged horizontally, and glued with a phenolic adhesive to form a 2m×1m×2.1mm two-layer plywood;

[0059] c) Fix the width of the two-ply board, and cut it into strips with the size of length × width × thickness 2m × 200mm × 2.1mm;

[0060] d) Mill out an 8mm-long bevel on each of the two end faces in the length direction of the slat.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com