Pressure cylinder with composite piston rod and method for preparing a composite piston rod

A composite material fiber and pressure cylinder technology, applied in the field of pressure cylinders, can solve the problems of weight reduction, high cost price, unsatisfactory, etc., and achieve the effect of additional reliability, fast and easy manufacturing, and high pressure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The drawings are only schematic and not drawn to scale. Some dimensions may be particularly exaggerated to larger or smaller extents for clarity. Corresponding parts are provided with the same reference symbols as far as possible in the figures.

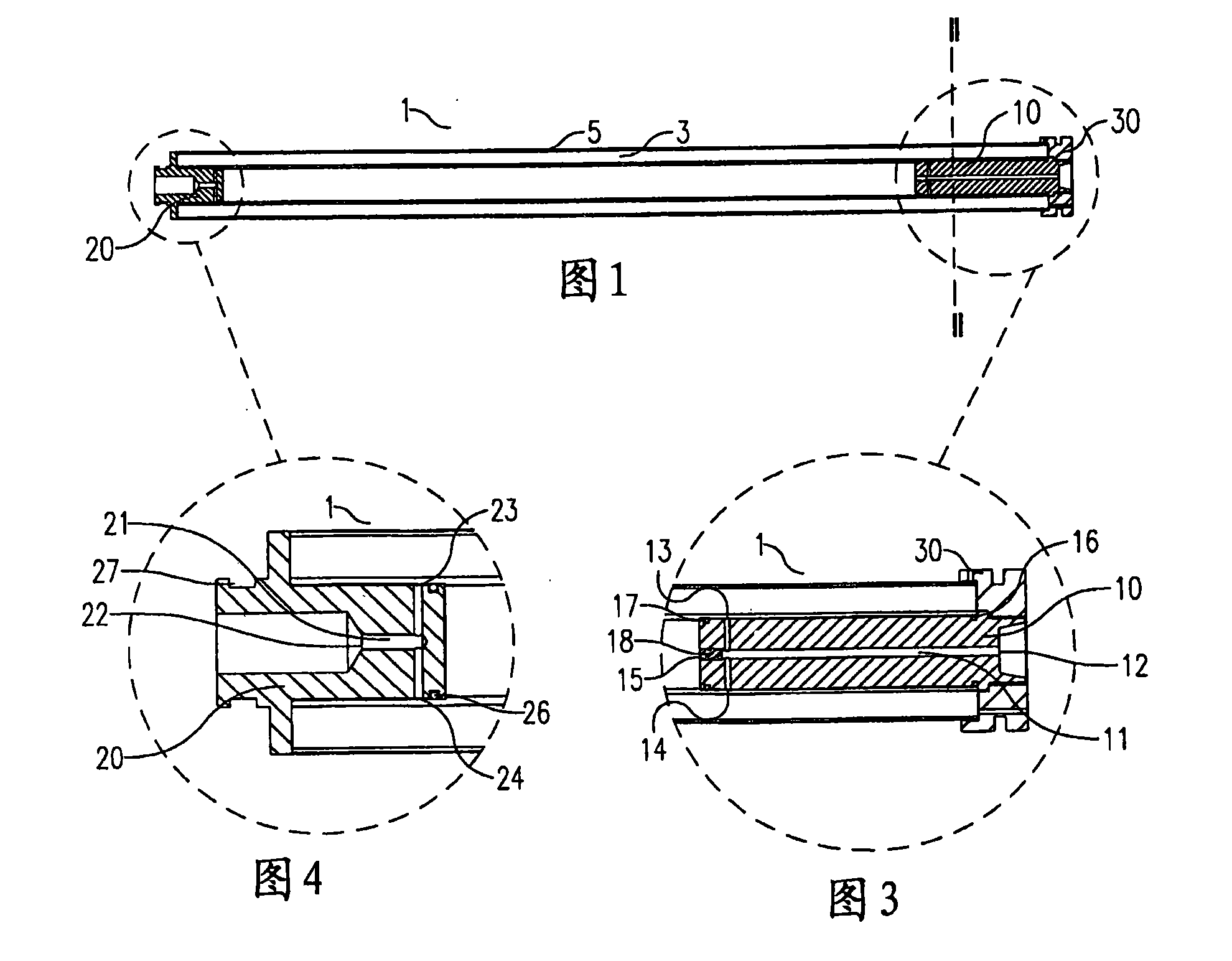

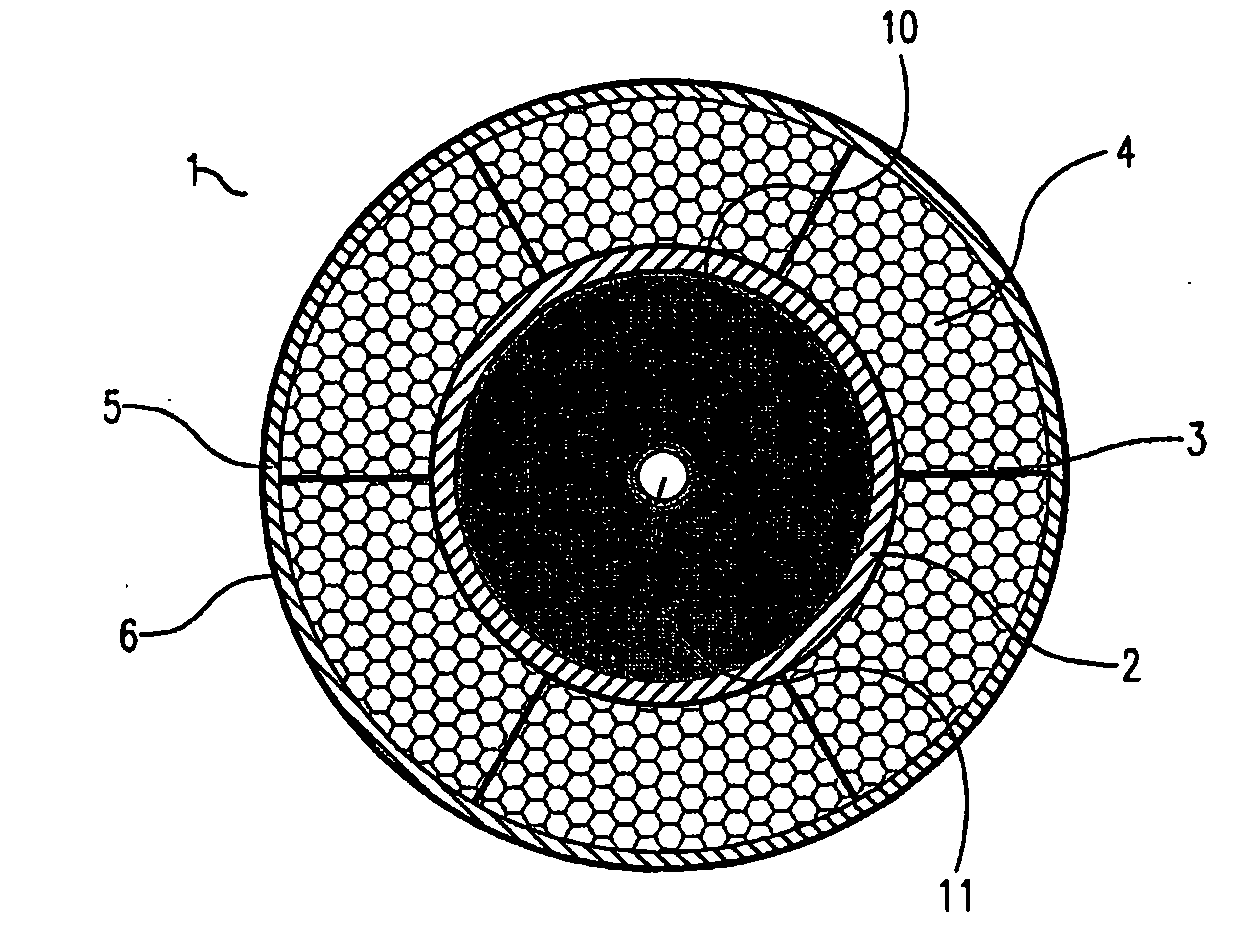

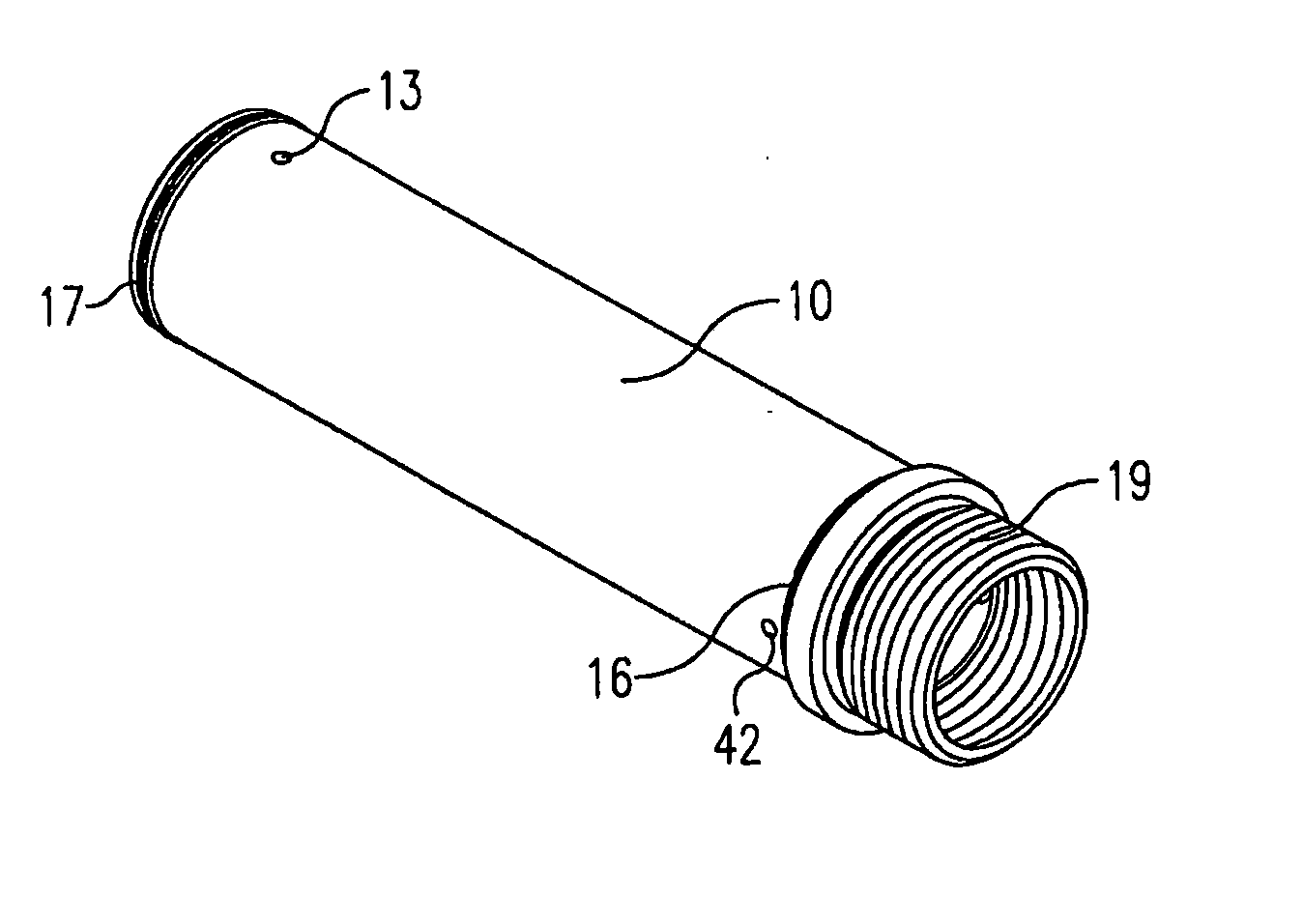

[0030] An exemplary embodiment of a piston rod used in a pressure cylinder according to the invention is shown in longitudinal section in figure 1 . The hollow piston rod 1 comprises a layer of core material 3 under a peripheral sheath 5 and is provided with an insert 10 at the proximal end and a closure 20 at the distal end. The distal end of the anodized high grade aluminum insert 10 is matingly bonded to the piston rod, while the proximal end of the insert 10 is screwed to the piston 30 by means of threads (not shown). The distal end of the insert 10 may also comprise a thread and thus be connected to the piston rod by means of a threaded connection.

[0031] figure 2 , 3 , 4 respectively show along the figure 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com