Hydraulic synchronous lifting hoisting technology and equipment for ultra-large members

A hydraulic synchronous lifting and ultra-large technology, applied in the direction of lifting devices, etc., can solve the problems that large cranes cannot complete hoisting, etc., and achieve the effects of high equipment automation, good safety and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

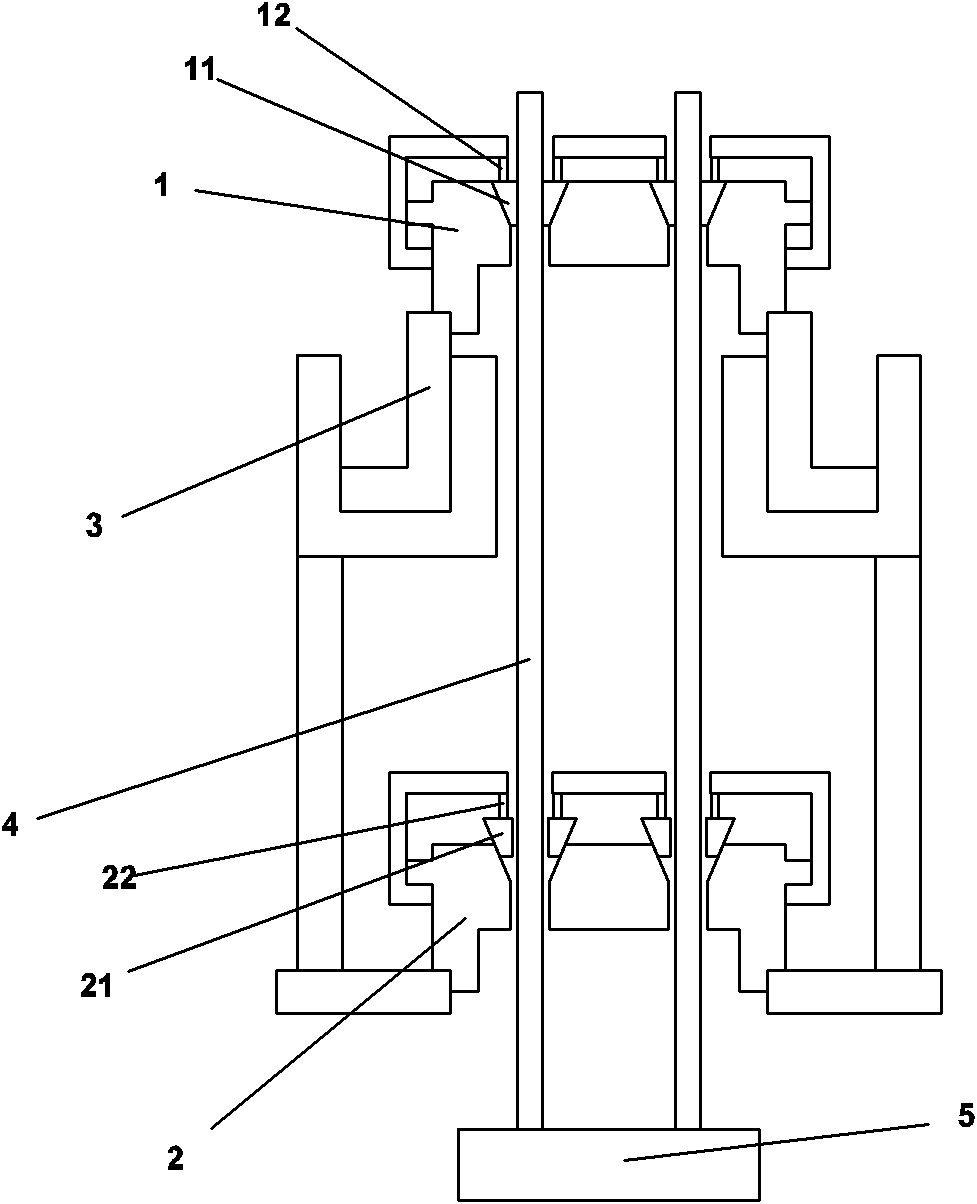

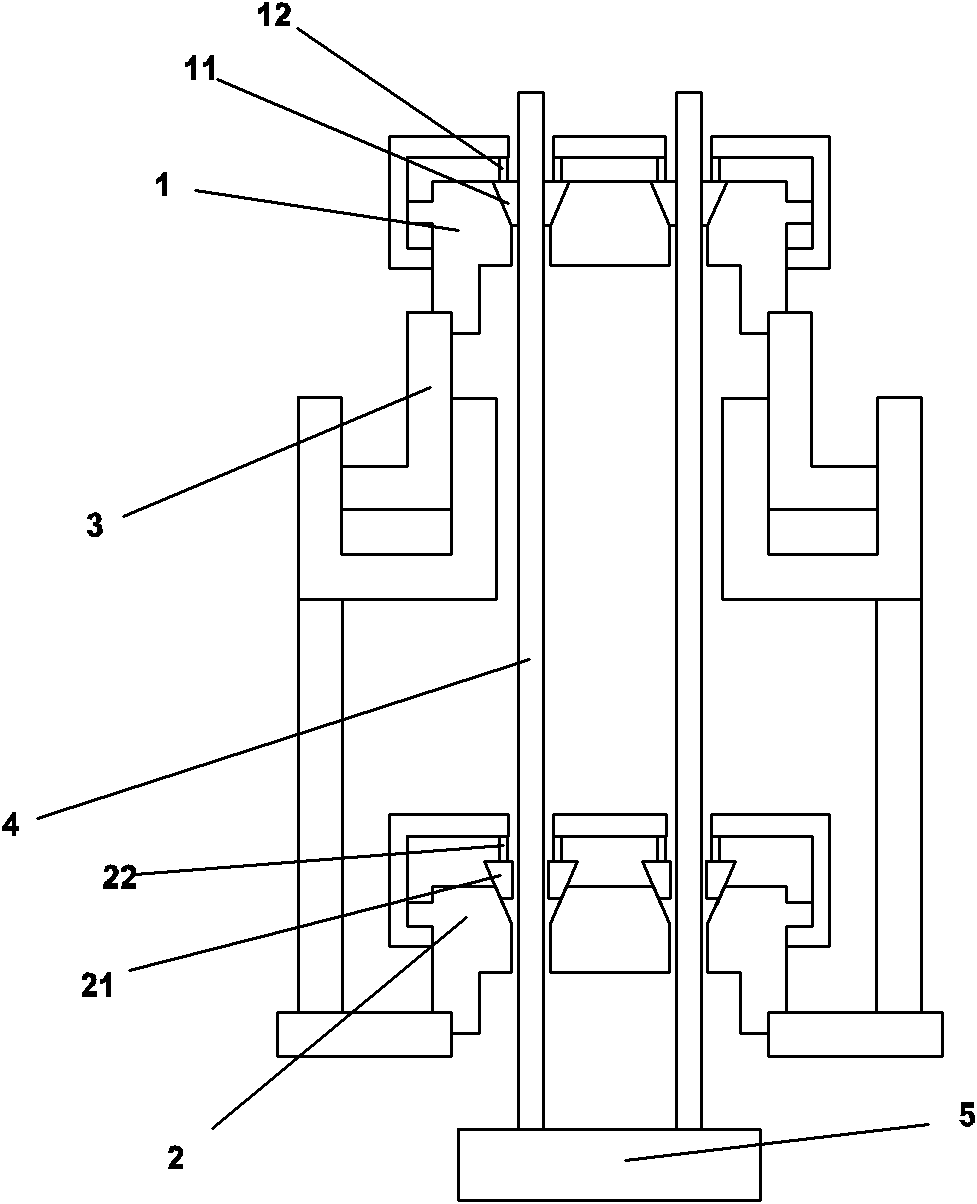

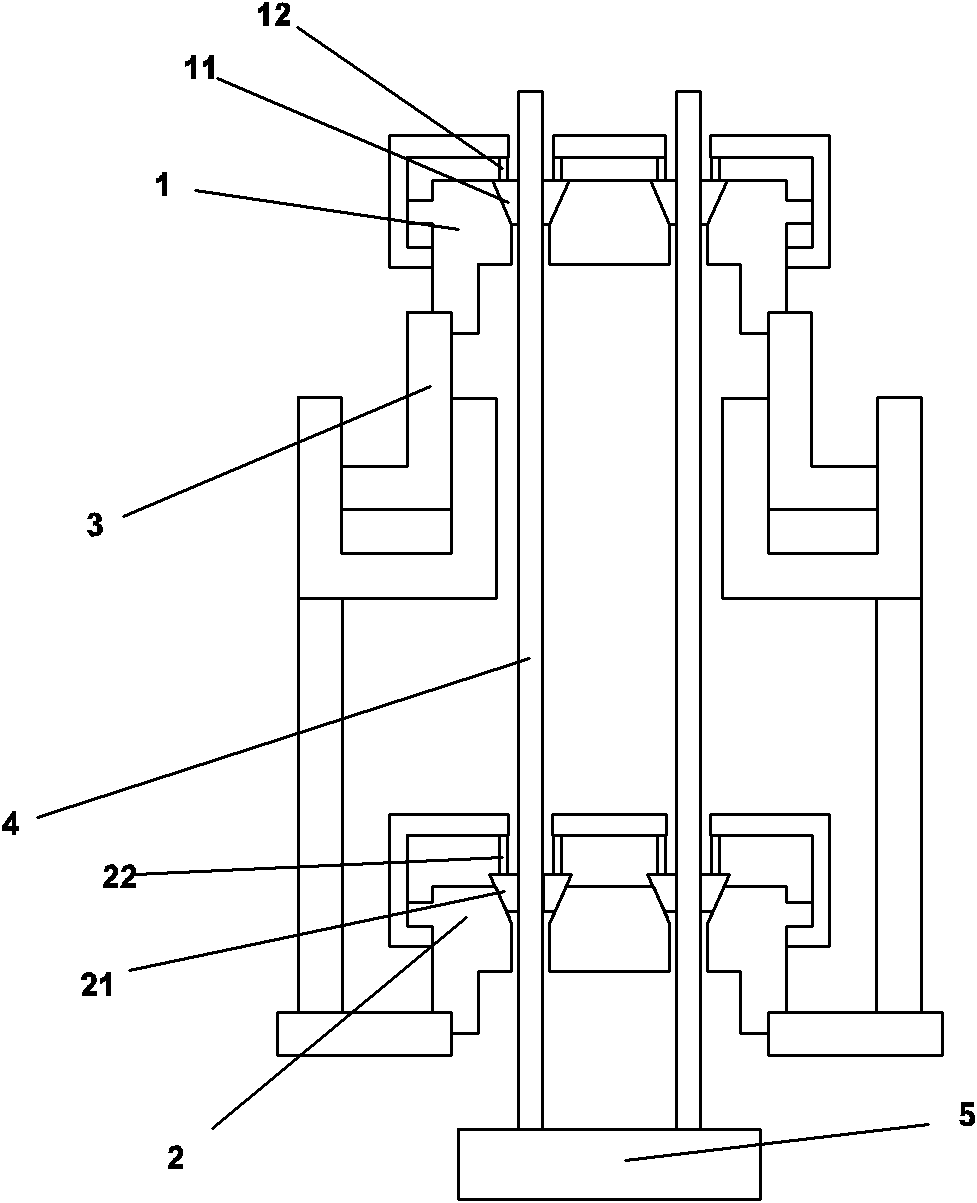

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, the structural composition of the present invention has upper support 1 and lower support 2, and lower support 2 is main support frame, and upper support 1 and lower support 2 are respectively provided with upper wedge-shaped anchor 11 and lower wedge-shaped anchor 21, last wedge-shaped anchor 11 and The lower wedge anchors 21 are self-locking downward wedge anchors; the upper wedge anchor 11 and the lower wedge anchor 21 are respectively connected to the upper anchor cylinder 12 and the lower anchor cylinder 22, that is, the upper anchor cylinder 12 and the lower anchor cylinder 22 can be controlled by telescopic The upper wedge-shaped anchor 11 and the lower wedge-shaped anchor 21 make it in a working state or a relaxed state. The upper bracket 1 is connected to the main cylinder 3. The main cylinder 3 can control the rise or fall of the upper bracket 1 through telescopic control, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com