Combined beam of FRP, wood and steel reinforced concrete

A technology of reinforced concrete and composite beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of low elastic modulus, large creep, and easy to be affected by the environment, so as to achieve convenient operation and improve bending stiffness and strength , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

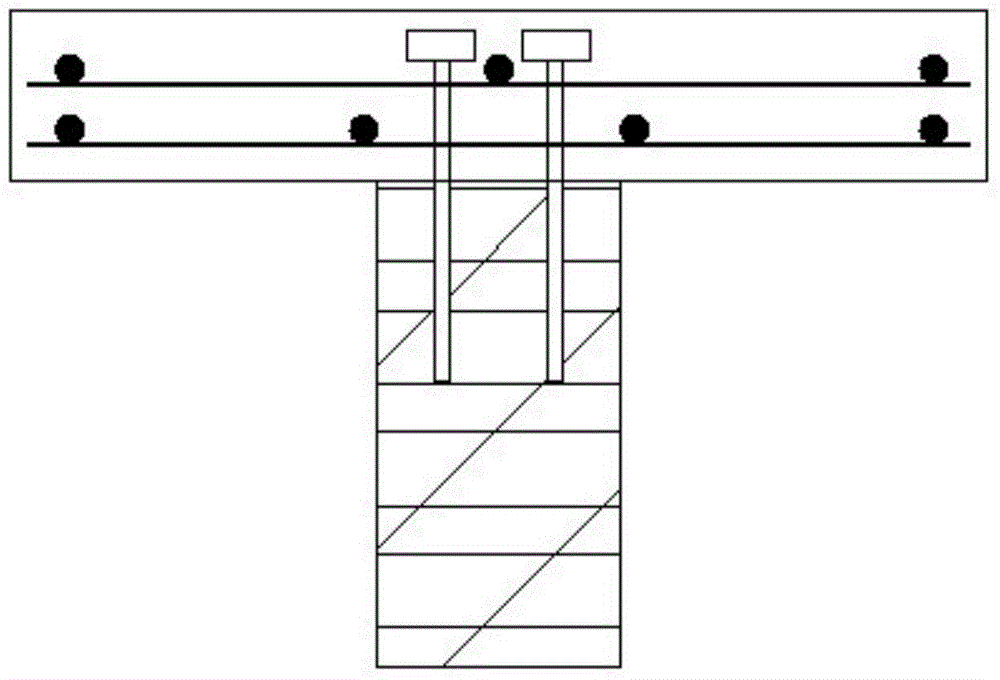

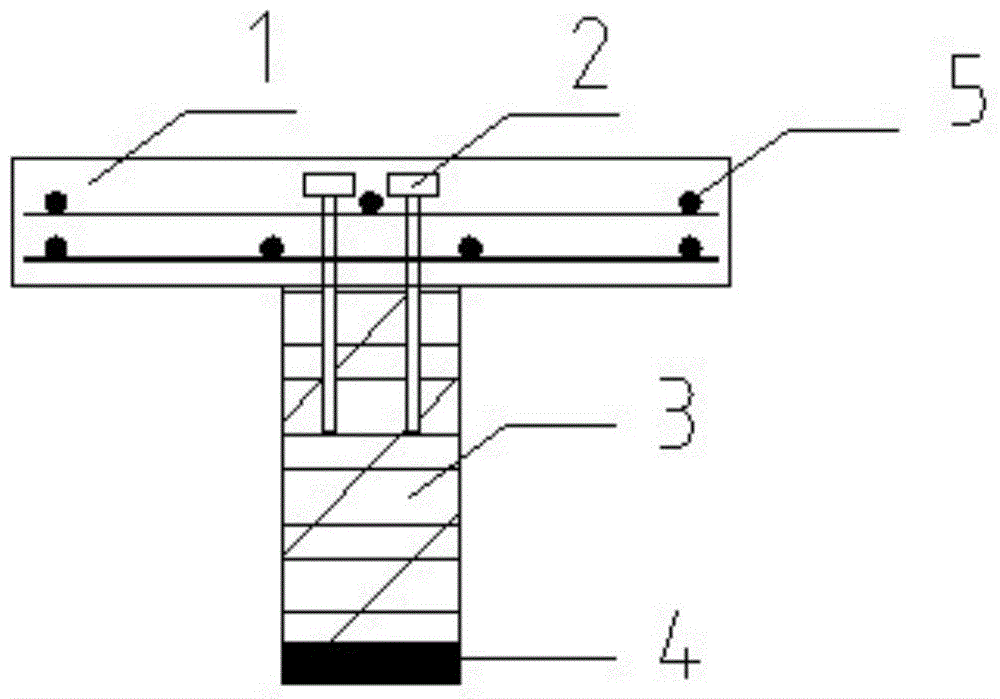

Method used

Image

Examples

Embodiment 1

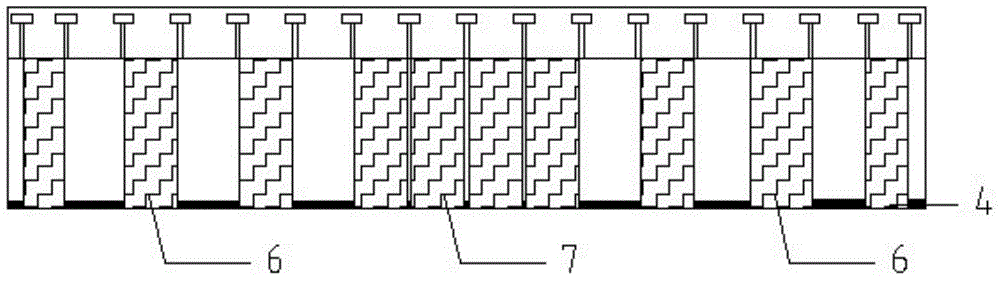

[0027] If the FRP reinforcement 4 provided at the bottom or middle and lower section of the wood-reinforced concrete composite beam can meet the strength design requirements, there is no need to continue to reinforce the composite beam, such as Figure 4 shown.

Embodiment 2

[0029] If the FRP reinforcement 4 set in the bottom or middle lower section of the wood-reinforced concrete composite beam and the FRP cloth set in the pure bending section cannot meet the strength design requirements, the FRP reinforcement 4 can be used in the lower side of the wooden beam 3 to continue reinforcement, such as Figure 5 shown.

Embodiment 3

[0031] Through calculation or detection, it is found that the neutral axis of the composite beam under load appears in the reinforced concrete wing plate of the wood-reinforced concrete composite beam, so the upper part of the side of the wooden beam 3 can be reinforced with FRP reinforcement 4, as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com