Flexible hangar tunnel used for isolating and protecting flying rocks or falling rocks

A shed hole and rockfall technology, which is applied in the direction of protective equipment, buildings, etc., can solve the problems of difficult construction of open holes or shed holes, and achieve the effects of reduced fixed strength requirements, reduced size requirements, high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

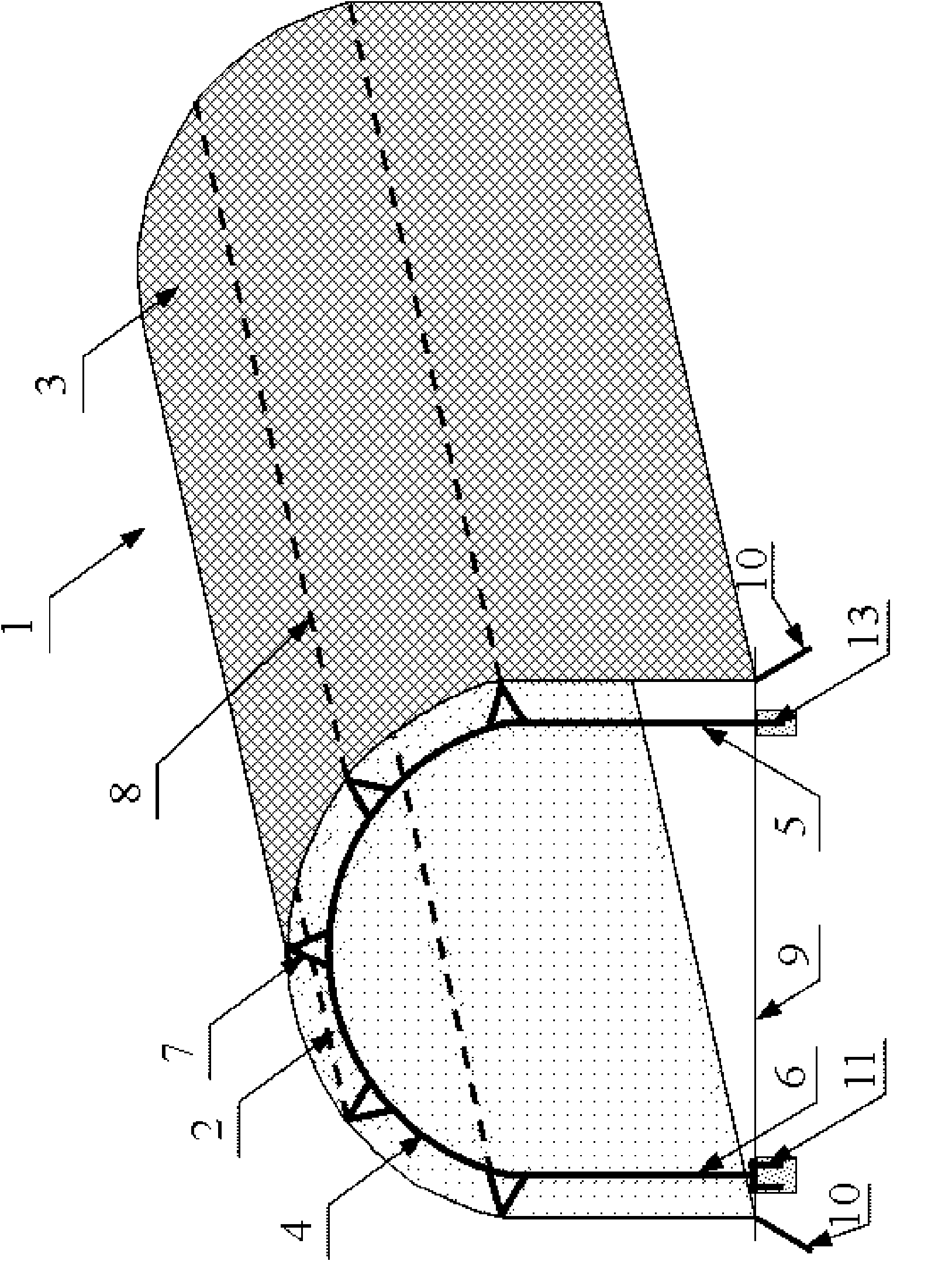

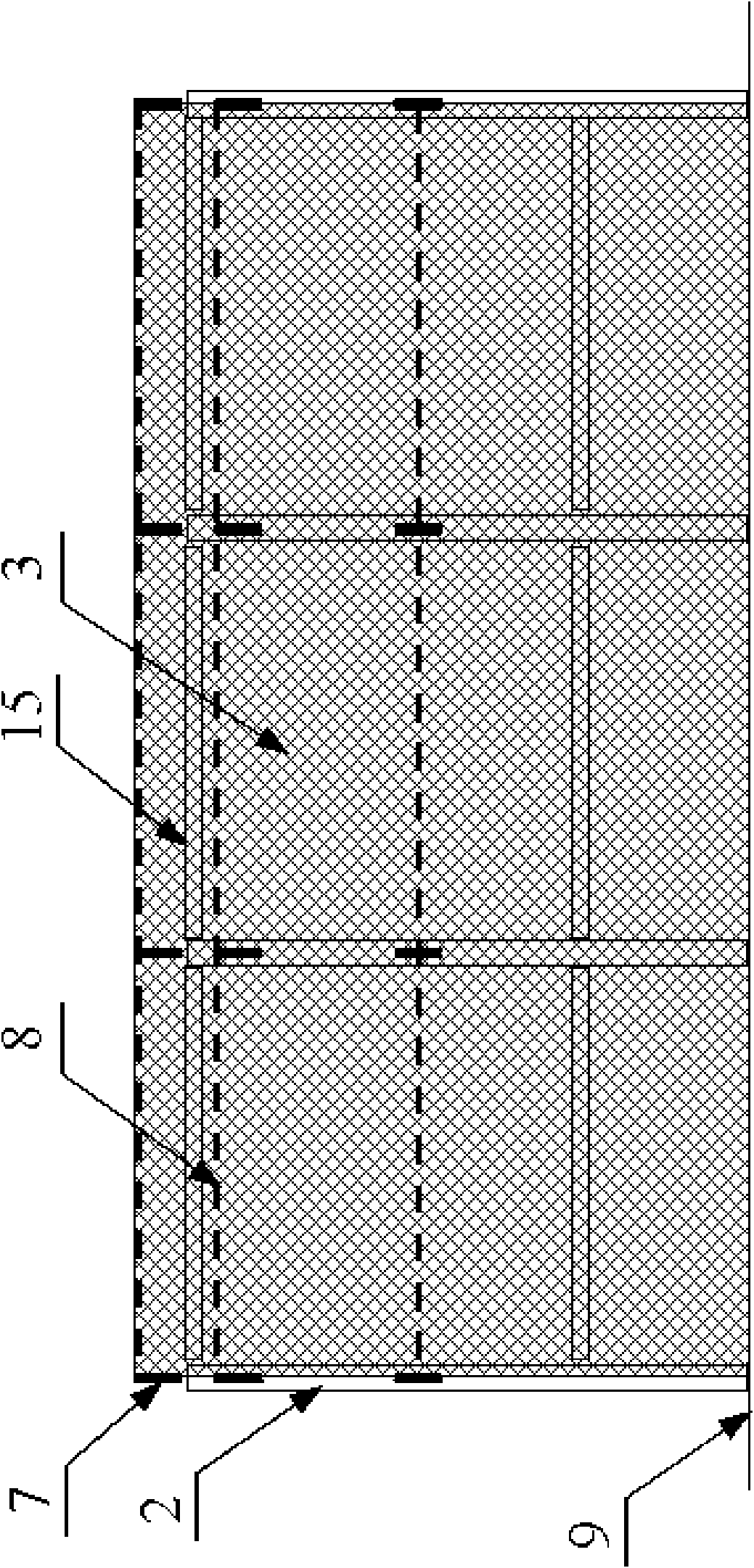

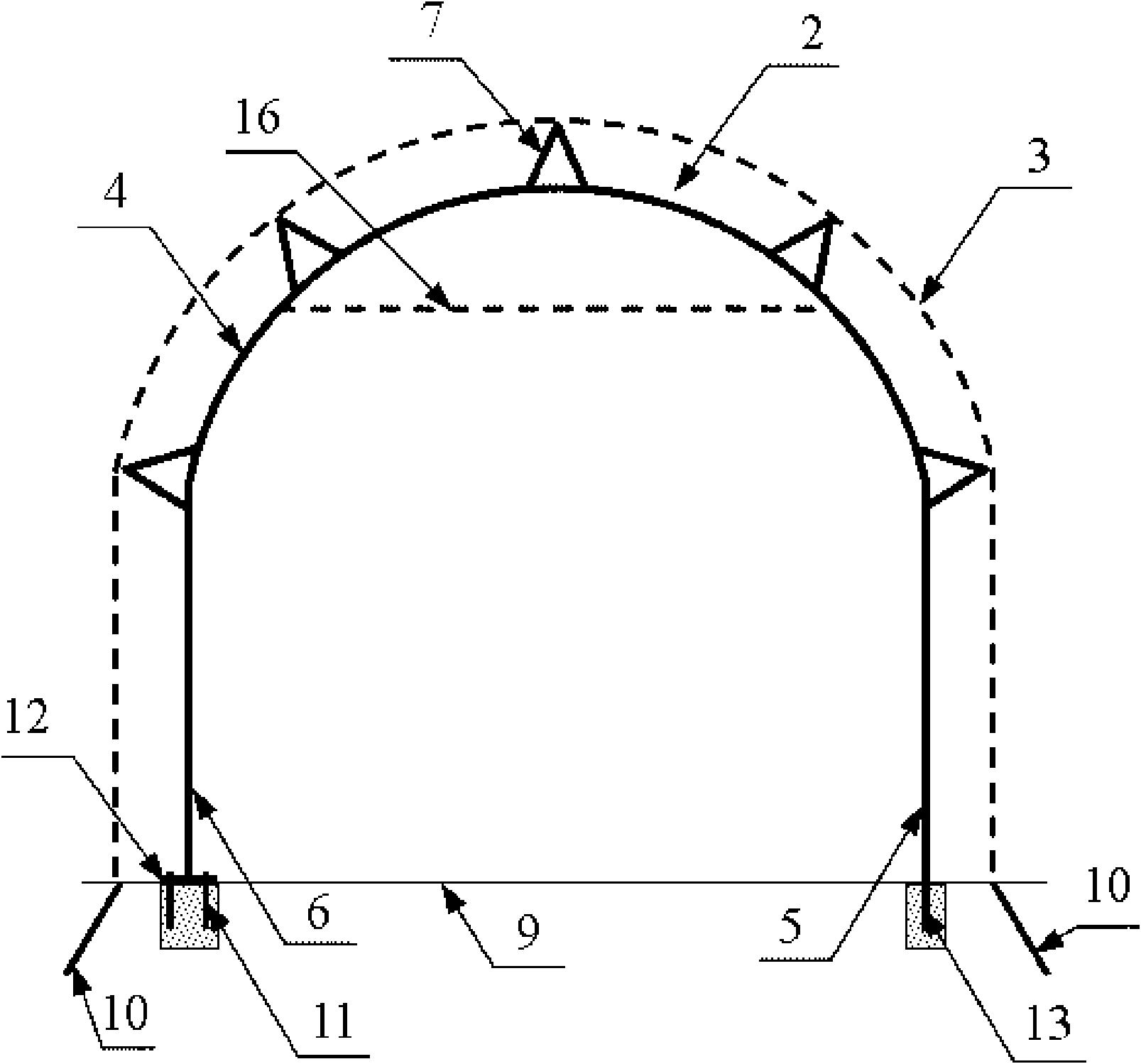

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the flexible shed cave for isolating and protecting flying rocks or falling rocks of the present invention, said shed cave is composed of at least two steel structure arches 2 arranged at intervals along the axis 14 and paving and hanging connected on the steel structure arches 2 Composed of at least one layer of metal mesh 3, the steel structure arch 2 is fixed on the foundation, the metal mesh 3 is located outside the steel structure arch 2 and connected to the foundation, preferably the drooping edge of the metal mesh 3 is at the same level as the ground 9 During installation, the steel structure arch 2 is arranged at a certain distance along the axis 14 until the entire installation length, and the metal mesh 3 is hung on or outside the steel structure arch 2 along the entire arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com