Side slope rockfall cushioning and protection system

A protection system and slope technology, applied in the field of slope protection and treatment, and rock slopes, can solve the problems of unsolved rockfall accumulation, falling rocks are easy to break through high-strength metal grid mesh and ring metal mesh, and achieve project implementation costs Effects of lowering, material reduction, and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

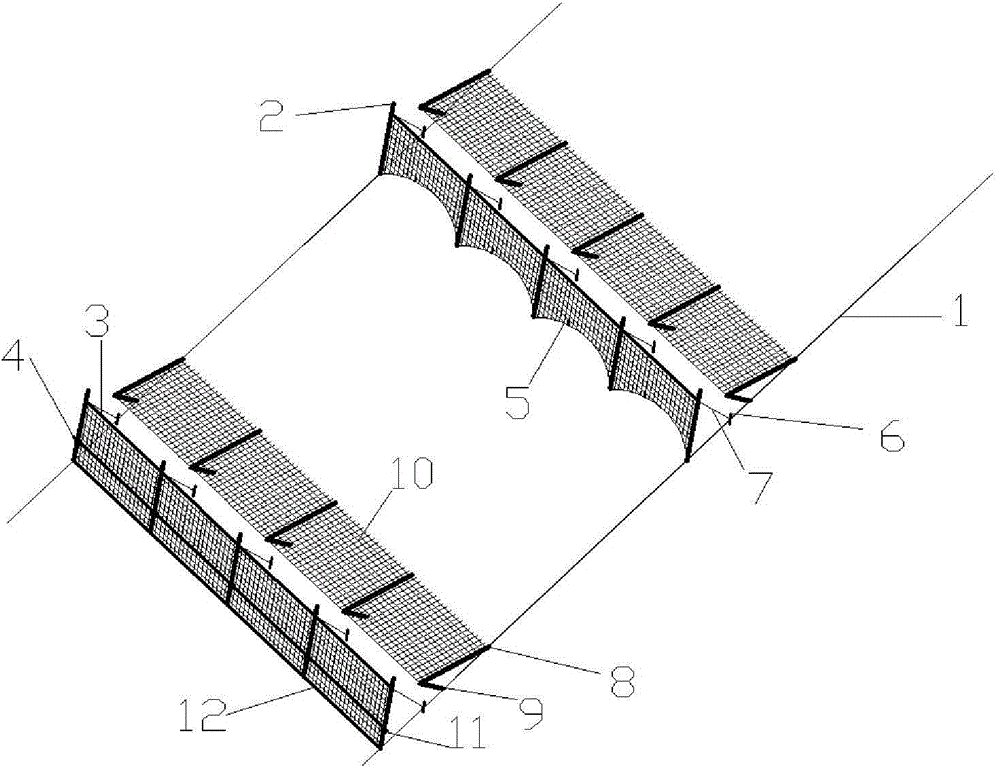

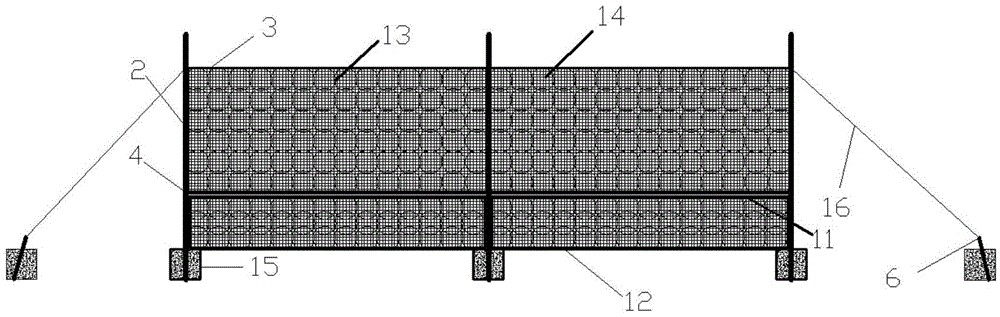

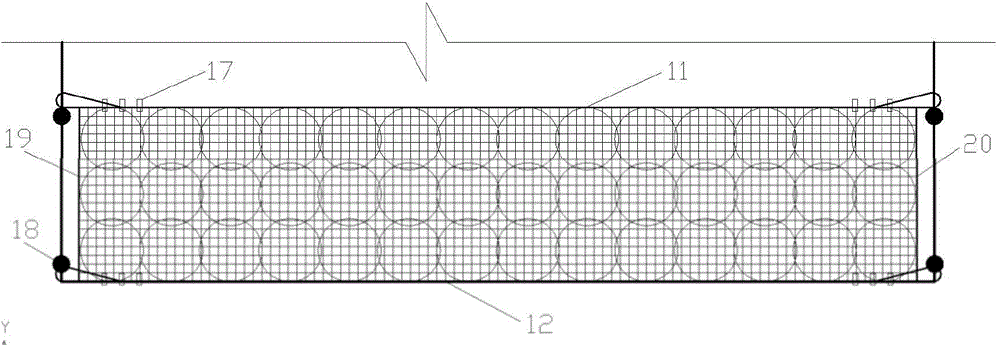

[0035] For a rock excavation slope with slope length S of 25m, a heavy protective layer is set on the slope.

[0036] Use measuring instruments to locate the location of each steel column. The horizontal spacing between adjacent steel columns of the same unit is 5m on the slope, and the net distance between the steel columns of the passive protection unit and the vertical steel columns of the energy-reducing buffer unit is 8m. Install each steel column at the positioning point in accordance with the current national or industry regulations, and meet the conditions: the steel column of the passive protection unit has a net height of 3.5m on the slope, and the angle α with the slope is 75°; the vertical steel column of the energy-reducing buffer unit is at The net height of the slope surface is 1.5m, and the included angle γ with the slope surface is 75°; the oblique steel column of the energy-reducing buffer unit has a net length of 3.5m on the slope surface, and the included an...

Embodiment 2

[0039] For a rock excavation slope with slope length S of 60m, double protection layers are set on the slope surface, and the net distance between the first and second protection layers is 25m.

[0040] Use measuring instruments to locate the location of each steel column. The horizontal spacing between adjacent steel columns of the same unit is 8m on the slope, and the net distance between the steel columns of the passive protection unit and the vertical steel columns of the energy-reducing buffer unit is 10m. Install each steel column at the positioning point in accordance with the current national or industry standards, and meet the conditions: the steel column of the passive protection unit has a net height of 5m on the slope, and the angle α with the slope is 105°; the vertical steel column of the energy-reducing buffer unit is on the slope The net height of the surface is 2m, and the included angle γ with the slope is 90°; the oblique steel column of the energy-reducing b...

Embodiment 3

[0043] For a rock excavation slope with slope length S of 75m, three protective layers are set on the slope surface, and the net distance between adjacent protective layers is 20m.

[0044] Use measuring instruments to locate the location of each steel column. The horizontal spacing between adjacent steel columns of the same unit is 8m on the slope, and the net distance between the steel columns of the passive protection unit and the vertical steel columns of the energy-reducing buffer unit is 10m. Install each steel column at the positioning point in accordance with the current national or industry standards, and meet the conditions: the steel column of the passive protection unit has a net height of 5m on the slope, and the angle α with the slope is 105°; the vertical steel column of the energy-reducing buffer unit is on the slope The net height of the surface is 2m, and the included angle γ with the slope is 90°; the oblique steel column of the energy-reducing buffer unit ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com