Small full-automatic hydraulic tamping wagon

A fully automatic, tamping vehicle technology, which is applied to the upper structure of the track, roads, tracks, etc., can solve the problems of expensive large-scale road maintenance machinery and equipment, high use costs, and affecting the progress of the project, so as to achieve stable tamping operations and improve The effect of work quality and traffic interference is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

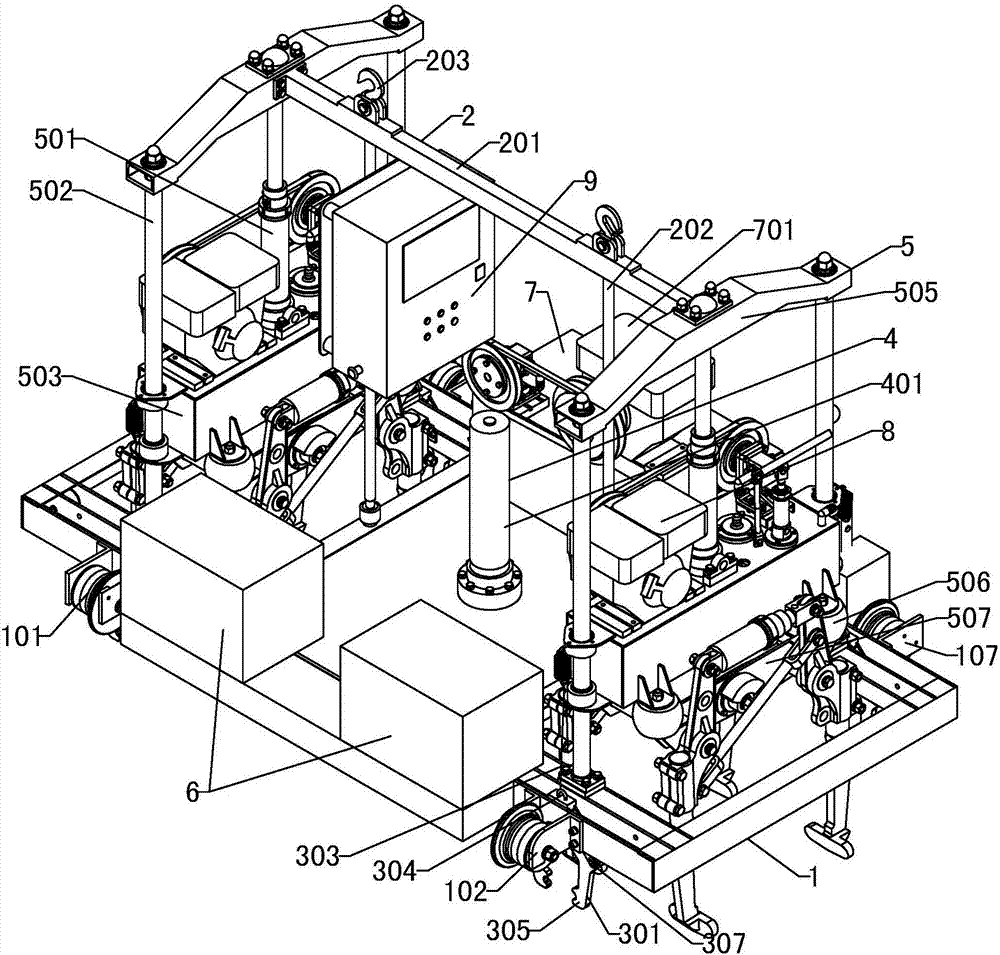

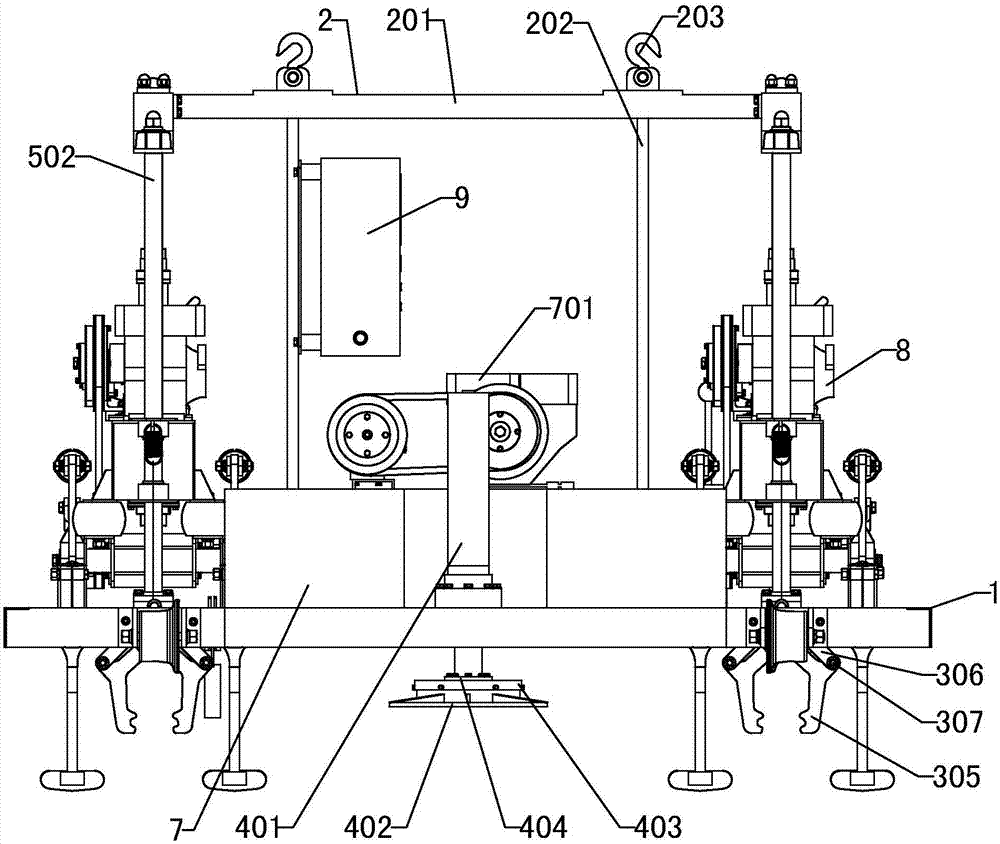

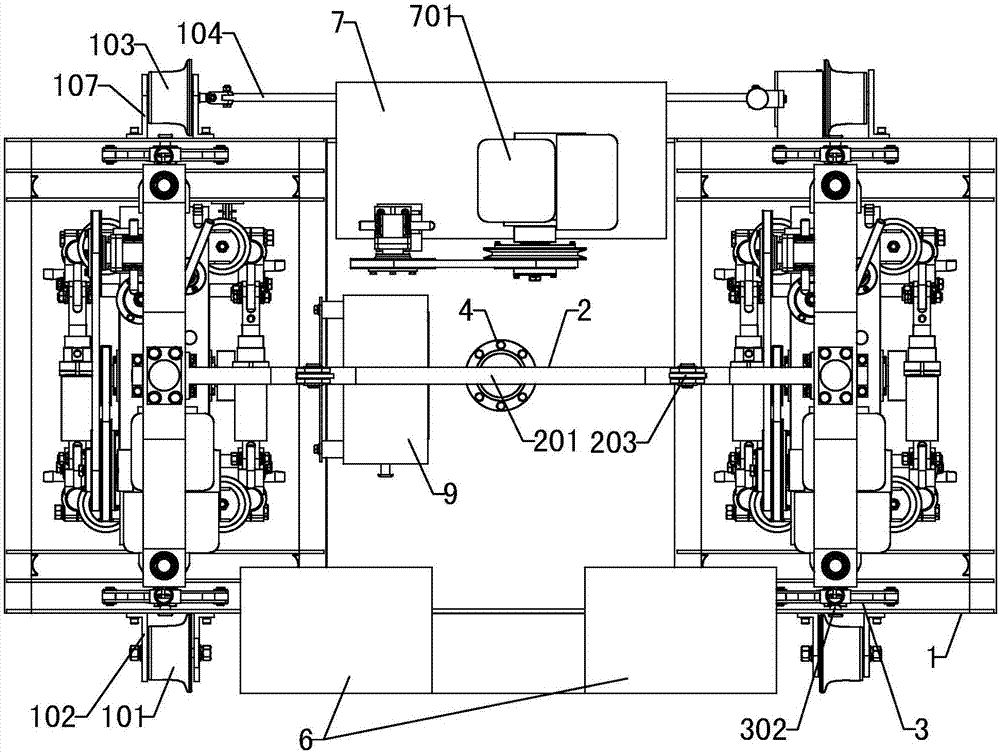

[0037] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0038] Refer to attached Figure 1~4 : Small automatic hydraulic tamping vehicle, comprising a tamping mechanism 5, the bottom of the tamping mechanism 5 is installed on the walking chassis 1, the lower part of the walking chassis 1 is provided with a walking mechanism to drive it to move, and the tamping mechanism 5 is provided There are two groups, two groups of tamping mechanisms 5 are symmetrically installed on the left and right sides of the walking chassis 1 walking direction, and the both sides of the walking chassis 1 walking direction are respectively provided with multiple groups of rail clamping mechanisms 3 for clamping the rails. There is a lower mechanism 4 that drives the whole machine up and down and can realize the rotation of the whole machine. Power devices are respectively provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com