Full-automatic numerical control hydraulic turnout tamping wagon

A fully automatic, tamping vehicle technology, applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of manual cooperation, equipment damage, low operation efficiency of portable small road maintenance equipment, etc., and achieve the effect of meeting the operation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

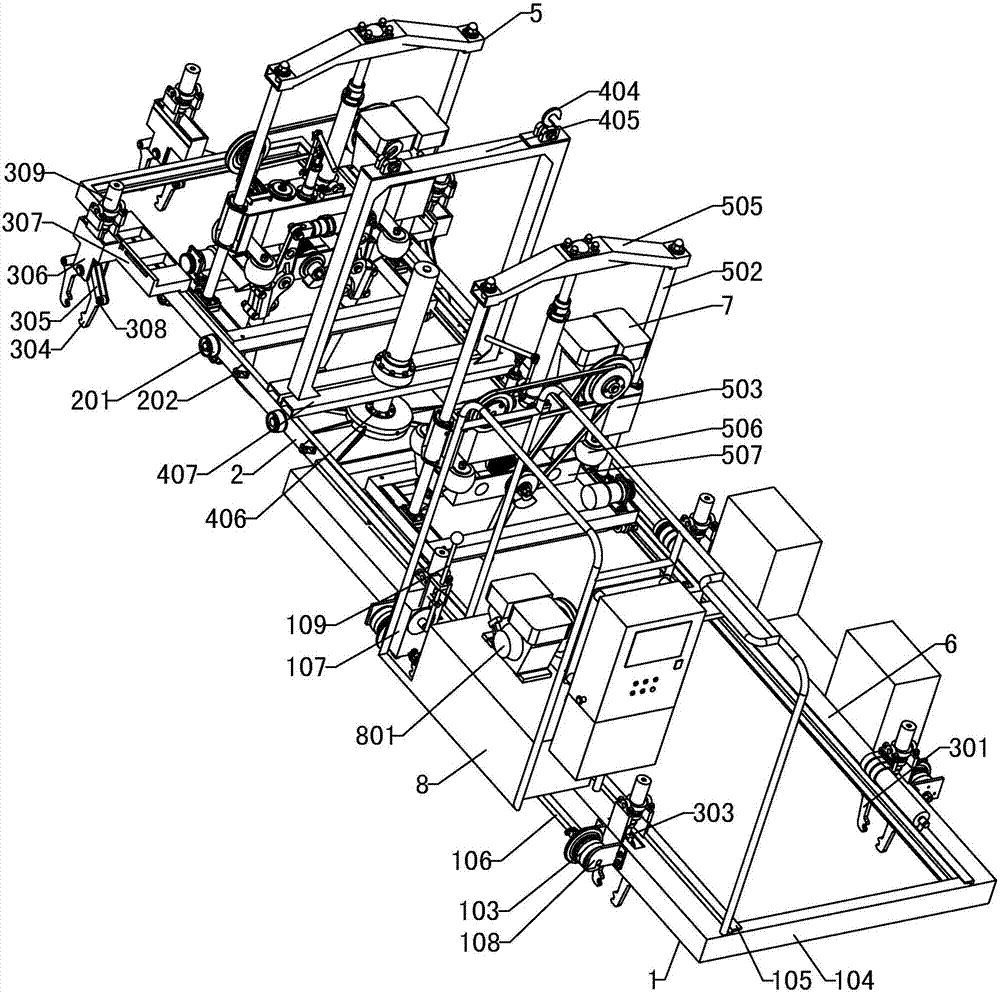

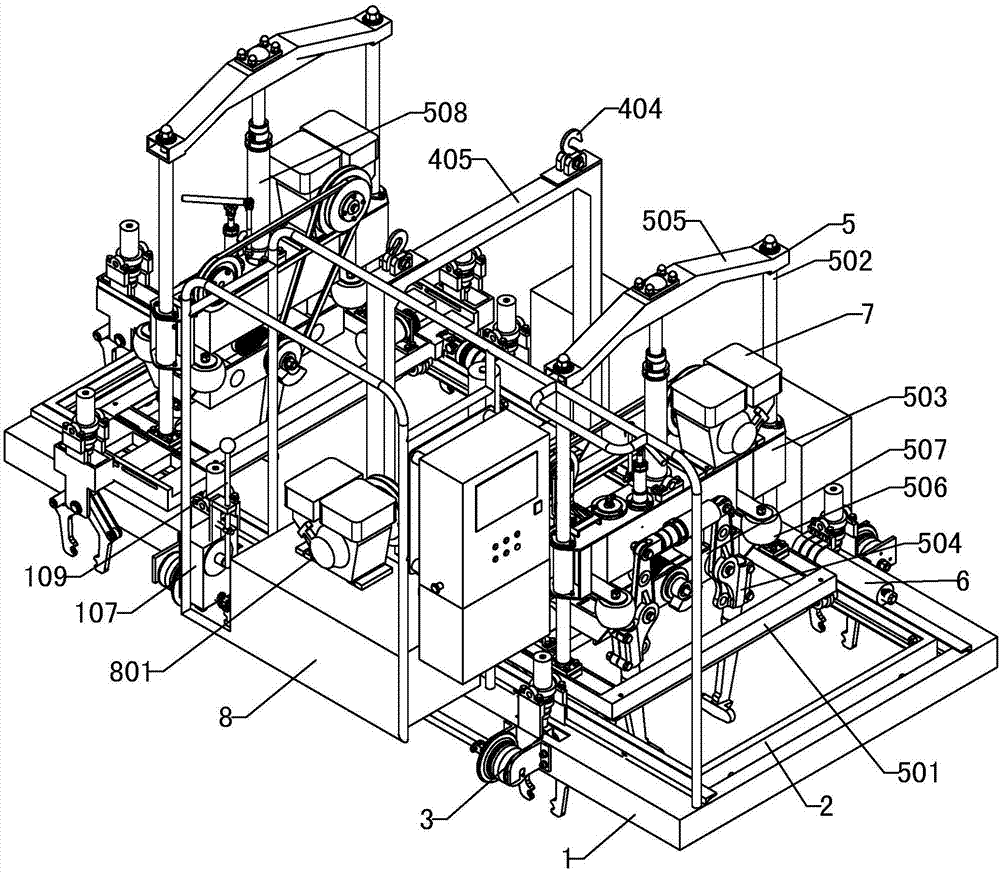

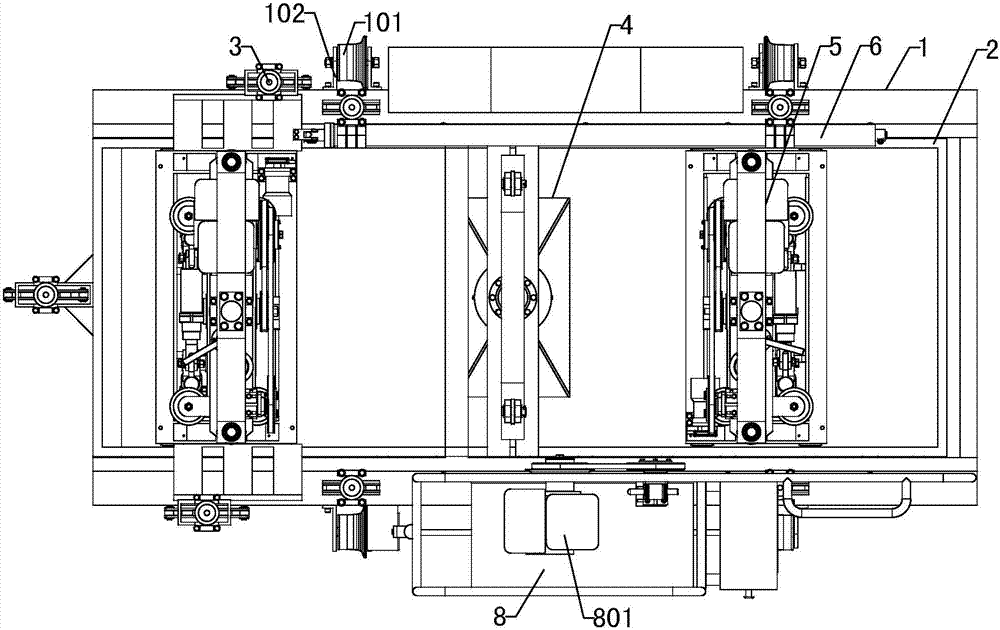

[0040] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0041] Refer to attached Figure 1~5 : Fully automatic CNC hydraulic turnout tamping vehicle, including a tamping mechanism 5, a self-propelled chassis is installed at the bottom of the tamping mechanism 5, the chassis includes a bottom walking chassis 1 and a mobile chassis 2, and the walking chassis 1 is front and rear along the railway line traveling direction The traveling mechanism is set, and the mobile chassis 2 is connected to the traveling chassis 1 in a horizontal and telescopic manner. The tamping mechanism 5 is provided with two groups. There is a rail clamping mechanism 3 for clamping the rail, and the middle part of the mobile chassis 2 is provided with a lower mechanism 4 that drives the whole machine up and down and can rotate; one side of the walking chassis 1 and a tamping mechanism 5 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com