SBR (styrene butadiene rubber) modified recycling agent for aged asphalt road surface in alpine regions, and preparation method and usage of the recycling agent

A technology for aging asphalt in alpine regions, applied in the field of SBR modified regenerant for thermal regeneration of asphalt pavement aging asphalt. Achieve the effects of improving storage stability, enhancing the anti-freezing and anti-cracking ability of the pavement, and excellent low-temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

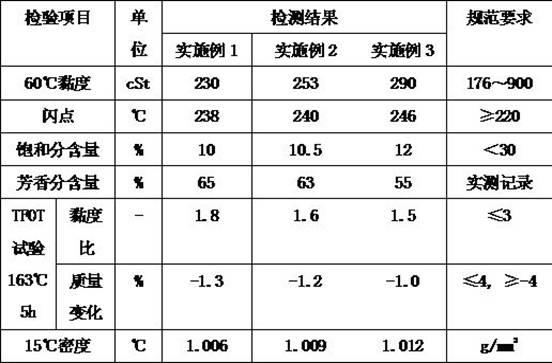

Examples

Embodiment 1

[0028] Example 1 SBR modified regenerating agent for aged asphalt pavement in high-cold area, mass percentage of each component:

[0029] Styrene butadiene rubber (SBR) 9.95%

[0030] 90A asphalt 60%

[0031] Extract oil 30%

[0032] Crosslinking agent 0.05%.

Embodiment 2

[0033] Example 2 SBR modifier and regeneration agent for aged asphalt pavement in high-cold area, mass percentage of each component:

[0034] Styrene Butadiene Rubber (SBR) 30%

[0035] 90A asphalt 15%

[0036] Extracted oil 54.8%

[0037] Crosslinking agent 0.2%.

Embodiment 3

[0038] Example 3 SBR modified regeneration agent for aged asphalt pavement in high-cold area, mass percentage of each component:

[0039] Styrene butadiene rubber (SBR) 19.9%

[0040] 90A asphalt 10%

[0041] Oil out 70%

[0042] Crosslinking agent 0.1%.

[0043] In the above embodiments: Esso 90A or Shell 90A is selected for 90A asphalt, with a ductility of 15°C> 100cm, softening point> 46°C, penetration degree 80-100; extracted oil is selected from furfural oil, vacuum residue, aromatic oil; crosslinking agent is selected from MAW asphalt crosslinking agent.

[0044] In the above embodiments, the preparation method of SBR modified regeneration agent for aged asphalt pavement in high-cold area:

[0045] According to the present invention, the mass percentage of each component of the SBR modified regeneration agent for the aged asphalt pavement in the alpine area,

[0046] ① Pump asphalt into the mixing tank, when the temperature is up to 120℃, pump in and extract the oil, keep the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com