Prefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes and construction method thereof

A technology of prefabricated assembly and bellows, which is applied in the direction of infrastructure engineering, erection/assembly of bridges, bridge parts, etc., can solve the problems of unsuitable assembly structure connection, difficult connection quality assurance, high construction accuracy requirements, etc., to achieve good The prospect of project promotion, fast and safe on-site construction, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

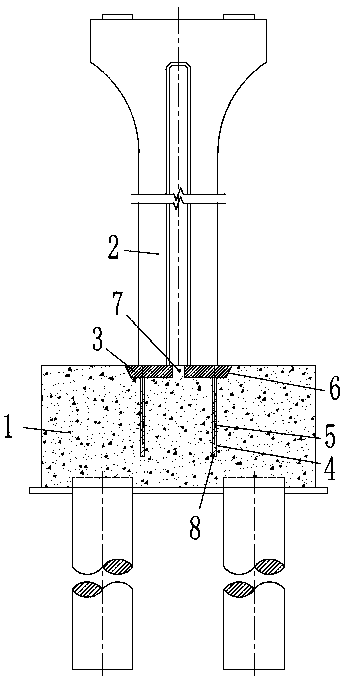

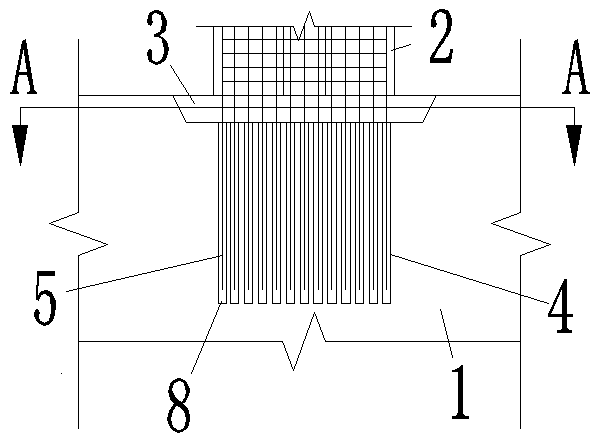

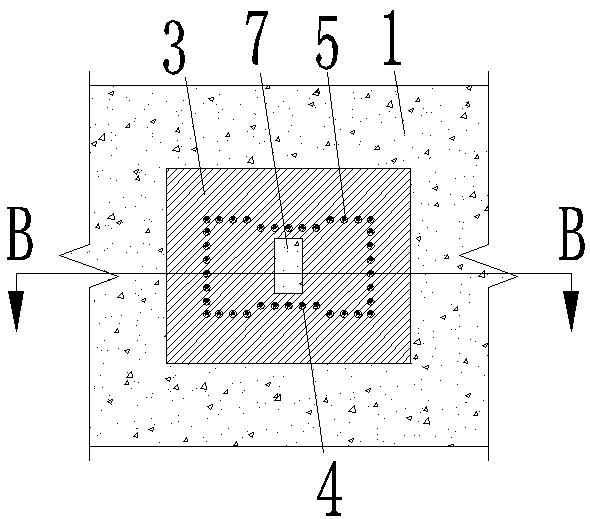

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0023] like Figure 1~5 As shown, a prefabricated assembled pier column structure connected by inserting steel bars into bellows, including a cap 1, a groove 6 is provided on the upper surface of the cap, and a support column 7 for supporting the bottom surface of the pier column 2 is provided inside the groove. Several corrugated pipes 4 are buried vertically around the support column inside the groove, and several main ribs 5 at the bottom of the pier correspond to the corrugated pipes one by one and are inserted into the corrugated pipe. Concrete fill layer 3.

[0024] In the embodiment of the present invention, vertical main reinforcement and transverse stirrup 9 are arranged inside the pier column, and the main reinforcement extends out of the bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com