Steel structure hangar tunnel and installation method

An installation method and steel structure technology, applied in the field of sheds and caves, can solve problems such as low line standards, long construction period, and large transportation interference, and achieve the effects of shortening construction time, fast construction progress, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

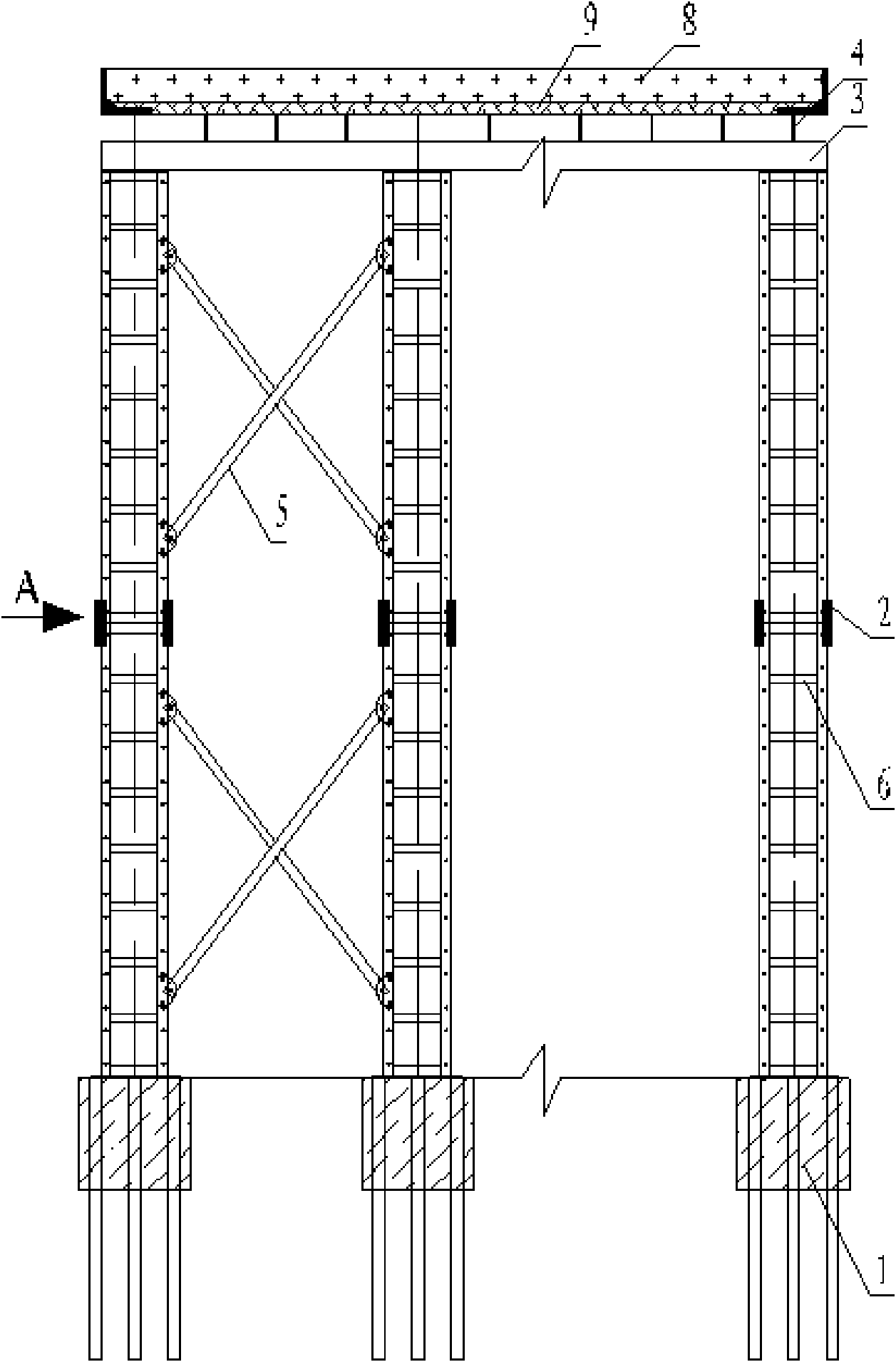

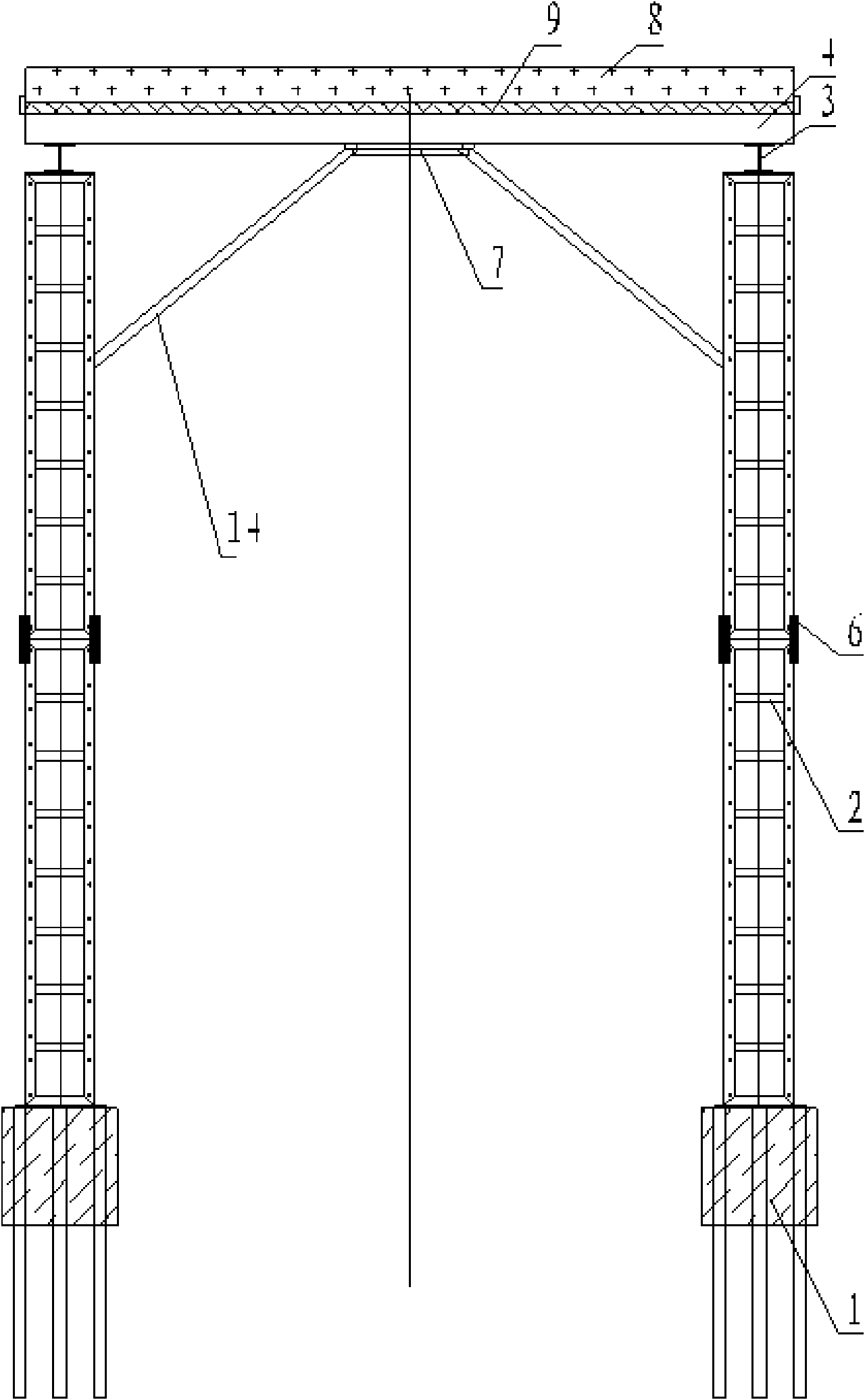

[0016] Embodiments of the present invention: first make parts such as steel pier 6, tie rod 5, longitudinal beam 3 and crossbeam 4 in the factory, make base 1 on the ground where the shed hole is built, steel pier 6 is installed on the base 1, According to the design height, the steel pier 6 is connected by bolts to assemble the column 2, the longitudinal beam 3 is fixed on the top of the column 2, the beam 4 is installed on the longitudinal beam 3, and finally the plank 9 and backfill soil 8 are laid on the beam 4 , you can get the shed hole. The tie rods 5 are connected between the columns 2 to ensure the structural stability of the shed hole. Insulating plate 7 is installed below crossbeam 4 to ensure safety, and oblique support 14 can also be installed between column 2 and crossbeam 4, improves stability.

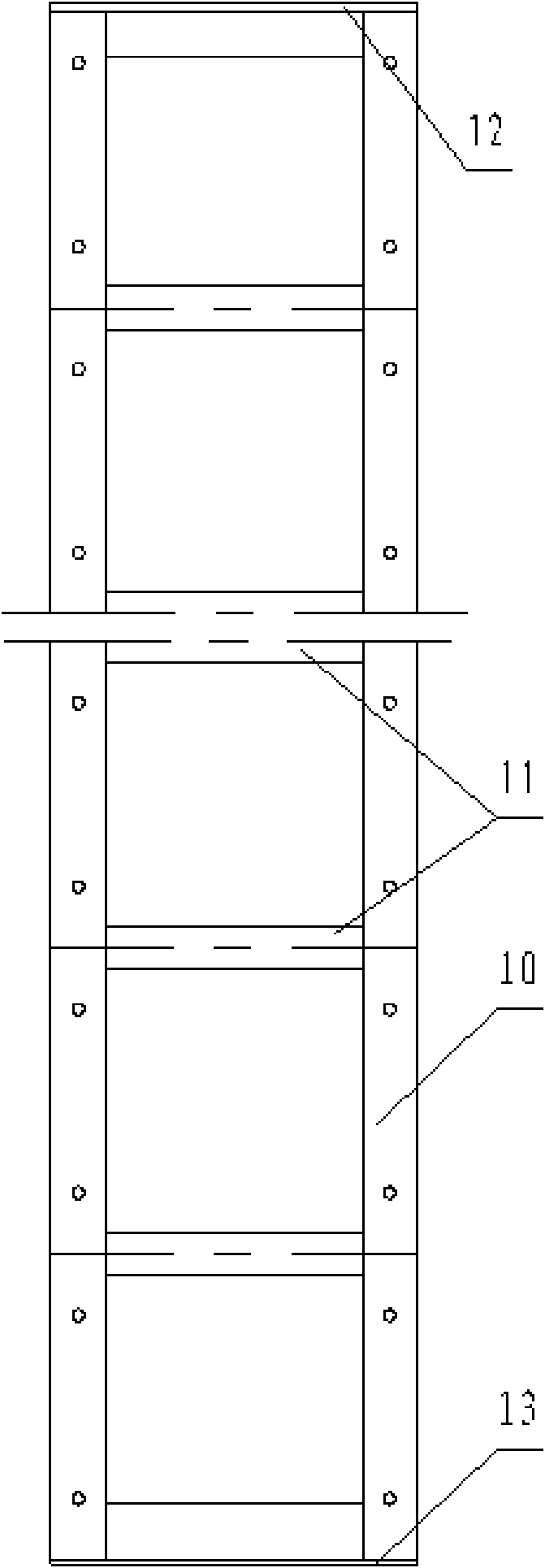

[0017] The structure of the steel pier 6 includes an upper iron plate 12 and a lower iron plate 13, four angle steels 10 are welded between the upper iron plate 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com