Preparation method of low-temperature recycled asphalt and mixture

An asphalt mixture and low-temperature regeneration technology, which is applied in the field of recycled asphalt, can solve the problems that the remaining value of asphalt pavement materials is not fully utilized, affects the technical performance of asphalt, and the aging of asphalt components. It is easy to purchase, easy to control quality, and pavement The effect of increased crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A low-temperature recycled asphalt mixture of this embodiment is composed of the following raw materials by mass percentage: including 25% of modified stone, 68% of recycled asphalt mixture, 4.5% of new asphalt, 2% of mineral powder, and 0.5% of asphalt regenerant .

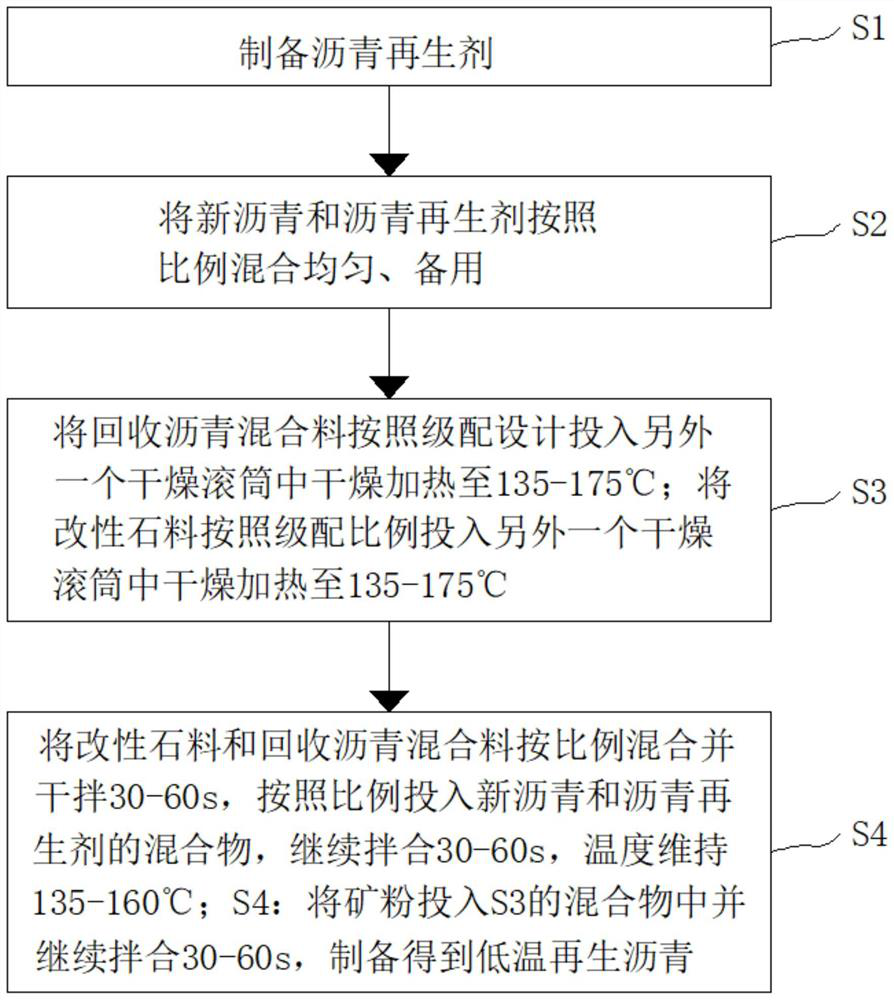

[0031] like figure 1 As shown, the preparation method of a kind of low-temperature regenerated asphalt mixture of this embodiment is:

[0032] S1: Preparation of asphalt rejuvenating agent;

[0033] S2: Mix the new asphalt and asphalt rejuvenating agent evenly according to the proportion and reserve;

[0034] S3: Put the recycled asphalt mixture into a drying drum according to the gradation design to dry and heat it to 120-150°C; put the modified stone into another drying drum according to the gradation ratio, dry and heat it to 135-175°C;

[0035] S4: Mix the modified stone and recycled asphalt mixture in proportion and dry mix for 30-60s, put in the mixture of new asphalt and asphalt regenerant accord...

Embodiment 2

[0046] The difference between this example and Example 1 is that the content of each component of the low-temperature regenerated asphalt mixture and the asphalt regenerant is different, specifically:

[0047] A low-temperature regenerated asphalt mixture of this embodiment is composed of the following raw materials by mass percentage: including 20% of modified stone, 75% of recycled asphalt mixture, 2% of new asphalt, 2% of mineral powder, and 1% of asphalt regenerant .

[0048] The asphalt rejuvenating agent involved in this embodiment is composed of the following raw materials by mass percentage:

[0049] It is composed of the following raw materials by mass percentage: 15% of solution-polymerized styrene-butadiene rubber, 50% of 90# petroleum asphalt, 31% of aromatic oil, 0.5% of crosslinking agent, 0.5% of plasticizer, 1.5% of dispersant, and 1.5% of stabilizer. .

Embodiment 3

[0051] The difference between this example and Examples 1 and 2 is the difference in the content of each component of the low-temperature regenerated asphalt mixture and the asphalt regenerant, specifically:

[0052] A low-temperature recycled asphalt mixture of this embodiment is composed of the following raw materials by mass percentage: including 35% modified stone, 55% recycled asphalt mixture, 6% new asphalt, 3% mineral powder, and 1% asphalt regenerant .

[0053] The asphalt rejuvenating agent involved in this embodiment is composed of the following raw materials by mass percentage:

[0054] It is composed of the following raw materials by mass percentage: 25% of solution-polymerized styrene-butadiene rubber, 35% of 90# petroleum asphalt, 35% of aromatic oil, 0.5% of crosslinking agent, 1.5% of plasticizer, 1% of dispersant, 2% of stabilizer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com