Steel cantilever combined bridge deck slab widening and reconstruction structure and construction method thereof

A technology for transforming structures and construction methods, applied in the direction of bridge reinforcement, bridges, bridge parts, etc., to achieve the effects of reliable quality, controllable construction period and little traffic disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

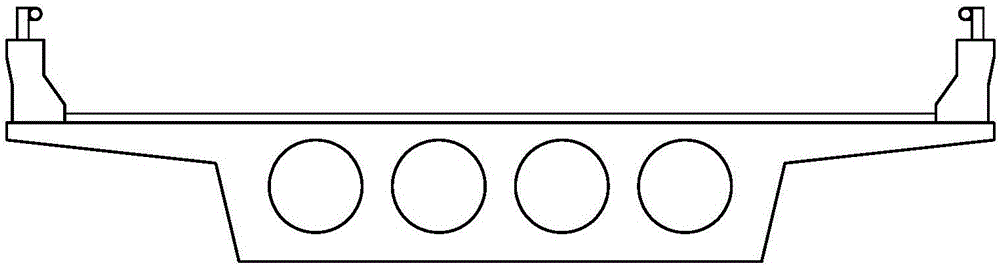

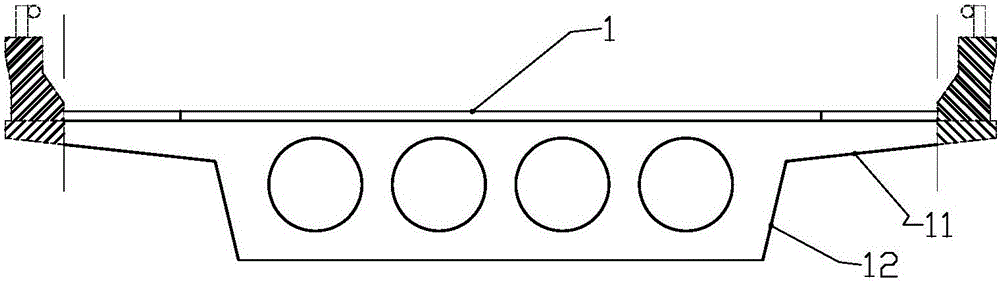

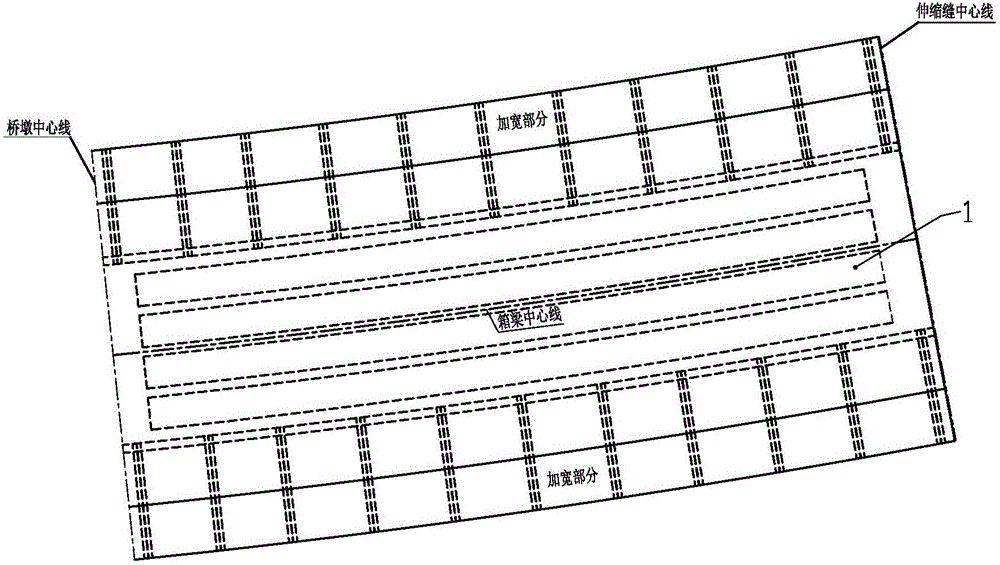

[0053] A plan to widen and transform the box girder of a steel cantilever composite bridge deck: the main part of the original box girder is retained, the cantilever ends on both sides (including the original bridge guardrail) are cut off, and the hollow steel cantilever is used as an auxiliary support. The composite bridge deck is extended from the original cantilever to the design width, and the concrete anti-collision guardrail of the original bridge is changed to a steel guardrail.

[0054] The reconstruction of the box girder by widening the steel cantilever composite bridge deck has certain restrictions on the widening capacity of the box girder. At the same time, it is necessary to reasonably determine the parameters such as the cutting position of the original box girder cantilever and the layout spacing of the steel cantilever along the bridge direction. The construction of the composite bridge deck should be considered. Convenience, and the impact of concrete shrinkag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com