Construction method of in-water pier and pier top beam section of bare rock riverbed

A construction method and technology of piers in water, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as difficult construction and large amount of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

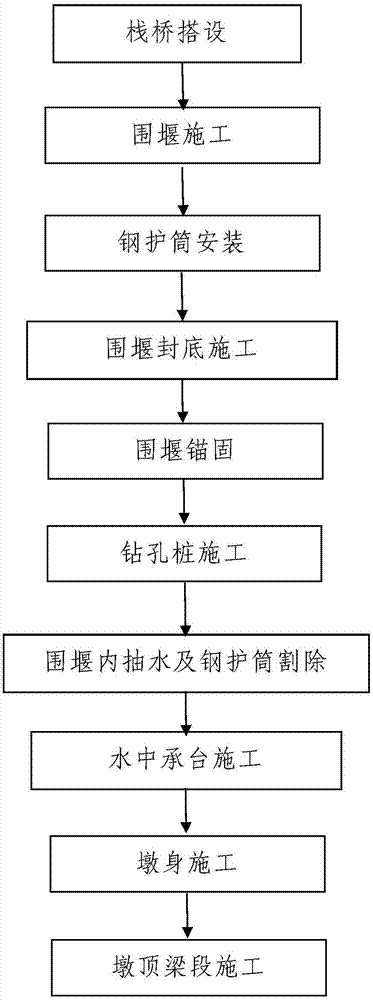

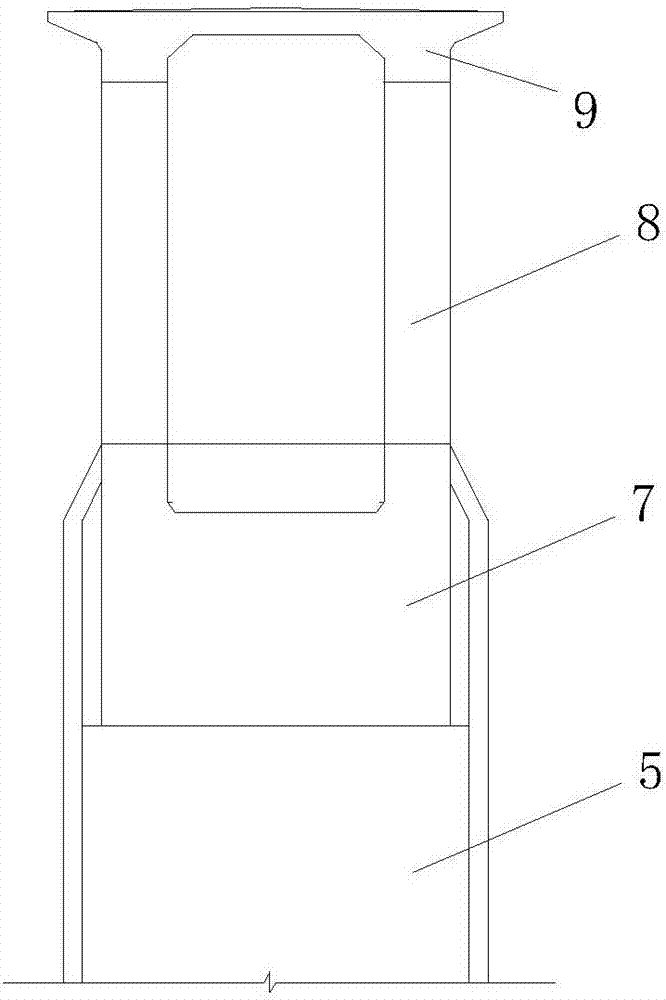

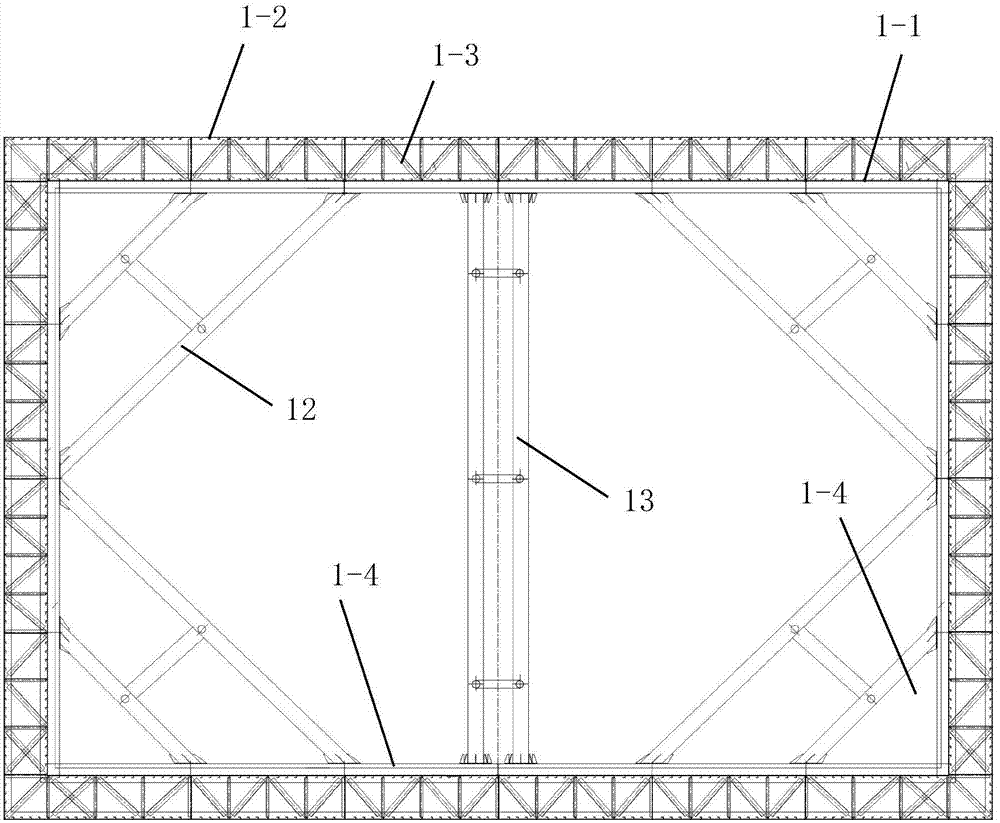

[0093] Such as figure 1 A kind of construction method of pier and pier top beam section shown in the bare rock riverbed, the pier in the water is a reinforced concrete pier supported on the bare rock riverbed 4-4, the pier in the water includes a pile foundation, supported on the pile The horizontal cap on the foundation and the pier body arranged on the horizontal cap, the height of the pier body is not less than 50m, see Picture 1-1 The horizontal cap is a reinforced concrete cap for construction using a steel cofferdam 1, the steel cofferdam 1 is a cubic steel box and its cross-section is rectangular, and the cubic steel box is divided into multiple sections from bottom to top. a cofferdam section arranged vertically, the cofferdam section at the bottom in the cubic steel box is a steel cofferdam bottom section; Figure 5 , the pile foundation includes N bored piles 17 supporting the horizontal cap, and the pier top beam section 14 supported on the water pier is a reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com